How Do Voyah Parts Maintain Structural Integrity and Safety in High-End Electric Vehicles?

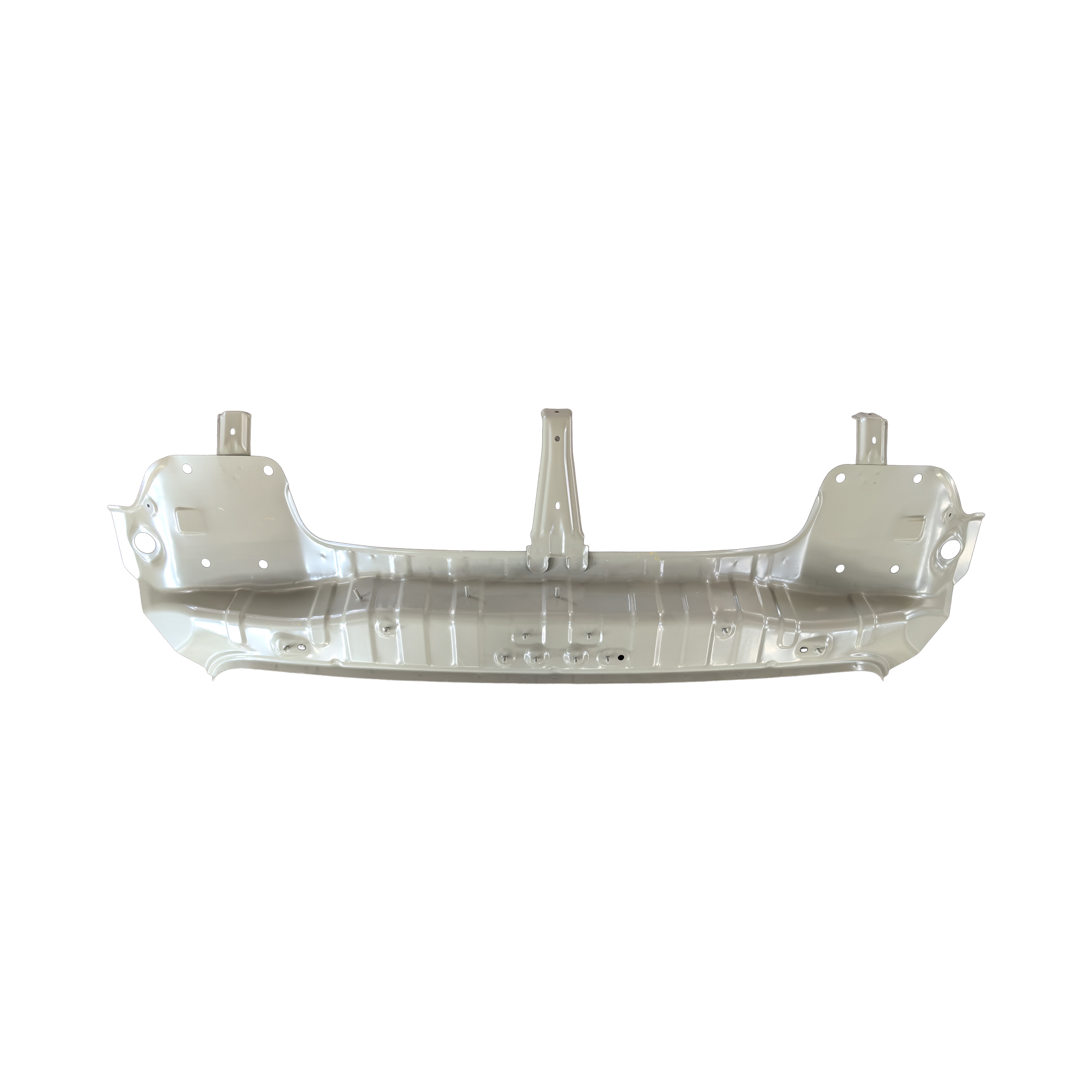

Modern high-end electric vehicles demand a combination of performance, lightweight construction, and precise styling. Voyah Parts provide metal sheet metal replacement components that preserve the structural framework of the vehicle while offering high impact resistance. Each panel, including doors, hoods, and bumpers, is engineered to match the original dimensions and strength specifications, ensuring that vehicles maintain designed energy absorption zones. This precision helps safeguard passengers during collisions and minimizes deformation in case of minor impacts, maintaining both safety and handling stability.

The high-strength alloys used in Voyah Parts are carefully selected to balance rigidity with flexibility. Panels can endure frequent vibrations, pressure, and environmental stress without permanent warping. Such durability is essential for flagship electric models where both lightweight design and robust structural support are required. The ability to absorb and distribute impact forces helps maintain passenger compartment integrity and supports the vehicle’s overall crashworthiness.

Corrosion resistance is another crucial factor for long-term safety. Urban and suburban driving conditions expose vehicles to moisture, road salts, and pollutants, which can compromise untreated metal over time. Voyah Parts feature anti-corrosion coatings and surface treatments that extend service life, preserving both functionality and appearance. Panels maintain their protective qualities even in challenging climates, ensuring vehicles remain reliable and safe throughout extended periods of use.

Jiangsu Juncheng Vehicle Industry Co., Ltd.’s expertise is particularly relevant here. With nearly a decade of specialization in automotive metal components, Juncheng combines precision engineering with advanced material selection to produce replacement parts that meet exacting safety and structural standards. Their robust quality management systems guarantee dimensional accuracy and consistent performance, which are critical for maintaining safety in high-end electric vehicles. By leveraging such industry-leading manufacturing practices, Voyah Parts achieve the reliability required for modern vehicle safety applications.

Durable Voyah sheet metal replacements also prevent secondary damage to adjacent components. Properly aligned panels reduce stress on suspension mounts, hinges, and electronic enclosures, protecting sensitive systems and maintaining long-term operational stability. This ensures that even after multiple repairs or maintenance cycles, the vehicle continues to meet design safety and structural specifications.

In What Ways Do Voyah Parts Support Efficient Maintenance and Appearance Restoration?

Efficiency in automotive repair relies heavily on parts that fit precisely and reduce the need for adjustment. Voyah Parts are manufactured to strict tolerances, allowing technicians to replace components without trimming or modifications. This precision ensures a streamlined workflow in workshops, reducing labor costs and installation errors. Vehicles are restored to original specifications, preserving both aesthetic quality and structural integrity.

The uniform surface and material consistency of Voyah Parts simplify painting, coating, and finishing processes. Replacement panels align seamlessly with adjacent structures, eliminating visible gaps and ensuring smooth, uniform surfaces. This allows for faster refinishing and reduces material waste, which is particularly important in high-end electric vehicles where design precision and visual quality are emphasized. Accurate fitment also supports energy efficiency by maintaining proper aerodynamics and surface alignment.

The modular nature of Voyah Parts enables broad application across multiple high-end models, such as the VOYAH FREE and VOYAH DREAMER, without requiring a wide range of unique inventory. Service centers can maintain fewer variations of stock while servicing complex repair and maintenance needs. Standardized design and high compatibility reduce troubleshooting during installation, supporting consistent, repeatable results.

Jiangsu Juncheng Vehicle Industry Co., Ltd. contributes to this efficiency through its advanced production technologies. By combining precision stamping, metal forming, and quality control processes, Juncheng ensures that each component fits exactly as intended. This reduces the risk of installation errors, supports workshop productivity, and ensures that repairs meet original equipment standards. Their ability to deliver high-quality components efficiently enhances the overall maintenance process for electric vehicles.

Using high-precision replacement parts also promotes environmentally responsible practices. Minimal trimming, reduced material waste, and fewer repeated refinishing cycles contribute to sustainable repair operations. This approach aligns with the demands of modern automotive workshops aiming to optimize cost, quality, and environmental performance simultaneously. The combination of reliability, precision, and efficiency ensures that Voyah Parts not only restore functionality but also enhance service quality in professional repair environments.

Why Are Durable Voyah Sheet Metal Replacement Parts Critical for Long-Term Vehicle Performance?

Long-term reliability in electric vehicles requires replacement parts that resist deformation, corrosion, and wear. Voyah Parts utilize high-strength metal alloys with advanced surface treatments to provide long-lasting structural stability. Panels retain their shape under repeated impact or pressure, ensuring that crumple zones and load-bearing areas continue to function as designed. This durability contributes directly to passenger protection and overall vehicle longevity.

Precision fit is essential for maintaining structural balance. Misaligned panels can transmit uneven stress to other components, causing accelerated wear, rattling, or misfit in doors, fenders, or adjacent body sections. Properly installed Voyah Parts preserve vehicle handling characteristics, noise reduction, and aerodynamic efficiency, all of which are especially critical for lightweight high-performance electric models.

Environmental resistance extends the lifespan of these replacement parts. Coatings and corrosion-resistant alloys protect panels against urban pollutants, moisture, and road salts. This ensures long-term visual appeal and prevents weakening of structural connections. Vehicles equipped with Voyah Parts require fewer interventions over their service life, supporting cost-effective ownership and maintaining the integrity of internal systems.

Internal systems such as battery enclosures, electronics, and suspension mounts rely on the protection provided by external panels. Durable sheet metal replacements act as shields against impact and environmental stress, ensuring the reliable performance of these sensitive components. Consistent quality and material strength reduce maintenance frequency while maintaining the functionality of critical systems, enhancing vehicle dependability.

Jiangsu Juncheng Vehicle Industry Co., Ltd.’s expertise further reinforces this reliability. Their experience in precision manufacturing and material selection ensures that Voyah Parts meet the stringent requirements of high-end electric vehicles. With robust quality assurance processes, Juncheng guarantees that each panel delivers consistent performance, contributing to long-term structural integrity, safety, and aesthetic quality. Their established position in the industry provides confidence to manufacturers and repair networks that the components will meet professional standards consistently.

Durable Voyah Parts also support economic and sustainable vehicle maintenance. Reduced part replacements, minimal material waste, and precise fit decrease both labor and material costs over the vehicle’s life. Electric vehicles, in particular, benefit from components that maintain light weight while providing structural reliability. This combination of efficiency, safety, and sustainability highlights the strategic importance of high-quality sheet metal replacement parts in modern automotive repair.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体