What Makes Lifan Parts an Important Component in Modern Automotive Body Repair?

Automotive body repair has evolved into a highly technical process where precision and material quality play a decisive role in vehicle safety and longevity. Lifan Parts represent a category of sheet metal replacement parts that cater to various Lifan vehicle models, ensuring that repairs restore both structure and design integrity. These metal body components, including hoods, fenders, door shells, and side panels, are carefully manufactured to match the exact specifications of original vehicles.

Each piece serves not only as an exterior shell but also as a critical element contributing to the vehicle’s safety framework. By replicating the geometry, thickness, and material strength of original body parts, these replacements ensure proper energy absorption during collisions, maintaining passenger protection levels. For workshops and repair centers, high-precision Lifan Parts make the replacement process more efficient, reducing fitting time and post-installation adjustments. In addition, their corrosion-resistant coatings extend the service life of the repaired vehicle, offering both durability and visual consistency.

The use of high-quality Lifan Parts in body repair also supports better workflow management within the automotive service industry. Technicians can rely on consistent sizing and predictable performance, which simplifies inventory planning and speeds up customer turnaround. This reliability builds customer trust, especially in competitive markets where speed and accuracy define success. The ability to perform quick and accurate repairs not only boosts productivity but also enhances the reputation of workshops that specialize in accident recovery or structural body replacement.

Modern manufacturing processes used in producing Lifan Parts involve advanced stamping, welding, and surface treatment methods. These ensure that every replacement component meets rigorous dimensional and mechanical standards. As a result, technicians can restore vehicles to their original condition without compromising safety or aesthetics. This precision-oriented approach reflects the overall evolution of the automotive body repair sector, where the focus lies on sustainable quality and dependable performance rather than short-term fixes.

How Do Lifan Parts Improve the Efficiency and Quality of Vehicle Maintenance?

Efficiency in automotive maintenance depends largely on the precision of replacement components. Lifan Parts are designed to simplify the repair process by maintaining high dimensional accuracy and compatibility. When mechanics work with poorly matched panels, issues such as gaps, alignment errors, and vibration noises often occur. The use of precisely engineered sheet metal replacement parts avoids these problems, ensuring a clean and accurate installation.

These components are manufactured using advanced metal forming and surface treatment technologies, ensuring both strength and a smooth finish suitable for painting and coating. Their structural stability supports long-term performance under stress, whether the vehicle operates in humid climates or experiences frequent vibration. The result is a seamless integration between new and existing components, improving both appearance and durability.

The efficiency advantages of Lifan Parts extend to the overall workflow in automotive workshops. Because these parts are designed to fit directly, technicians can save significant time during the installation process. The simplified replacement process reduces the need for post-repair alignment or refinishing work, which lowers labor costs and improves customer satisfaction. This level of accuracy enables repair businesses to handle more vehicles in less time, leading to higher operational output and profitability.

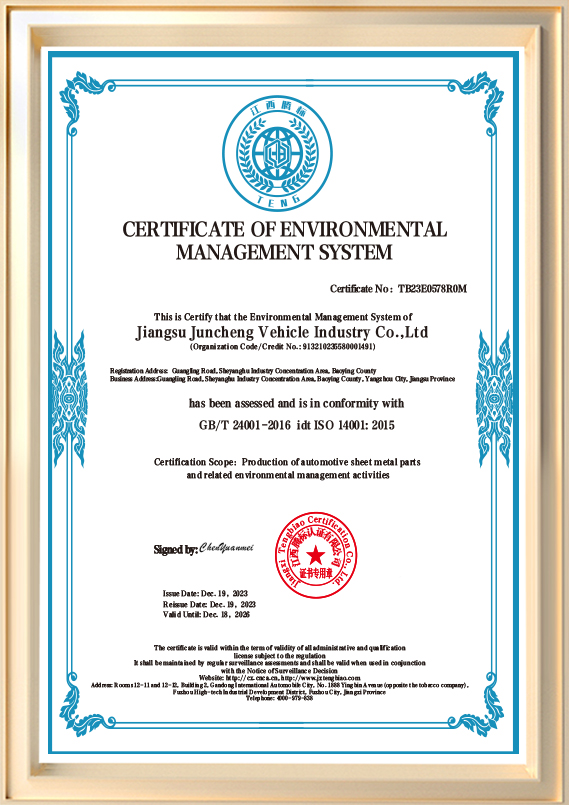

Beyond mechanical efficiency, Lifan Parts also play an important role in maintaining environmental responsibility within the repair process. Their precise engineering minimizes material waste, and their corrosion-resistant coatings help extend product life. This sustainable approach aligns with the growing demand for eco-friendly repair solutions that reduce unnecessary material consumption. By combining strength, fit accuracy, and long-term durability, Lifan Parts contribute to a more efficient, cleaner, and cost-effective automotive repair environment.

The application of Lifan Parts also enhances quality control in the maintenance process. Inconsistent materials or substandard components often lead to premature wear and compromised structural stability. Lifan Parts, produced through strict quality management systems, ensure uniform material composition and consistent performance in all conditions. This reliability allows repair technicians to maintain the same level of quality across multiple service projects, improving customer confidence and minimizing warranty claims. A well-fitting body panel not only restores the visual appeal of the vehicle but also preserves its aerodynamic balance, which contributes to improved fuel efficiency and handling stability.

Additionally, the durability of Lifan Parts supports long-term maintenance strategies. Their ability to withstand exposure to moisture, temperature changes, and mechanical stress makes them particularly suitable for vehicles operating under demanding conditions. This resilience reduces the frequency of follow-up repairs and protects critical internal systems from external damage. By using durable sheet metal components, workshops can offer extended maintenance intervals and ensure that each vehicle remains safe and aesthetically consistent for years. The consistent performance of these parts reflects a professional commitment to precision and reliability within the modern automotive repair industry.

Why Are High-Precision Sheet Metal Replacement Parts Essential for Automotive Longevity?

Modern vehicles rely heavily on the integrity of their outer and inner body structures to maintain overall stability. Sheet metal components play a central role in protecting vital systems such as the engine bay, cabin, and suspension mounts. Lifan Parts are developed with a focus on dimensional fidelity and material quality, which helps preserve vehicle geometry after repairs. Precision replacement ensures that safety zones, crumple areas, and attachment points remain aligned as designed.

Automotive longevity depends not only on engine performance but also on the preservation of the vehicle’s frame and surface. High-quality sheet metal replacement parts resist corrosion and deformation, preventing long-term degradation caused by environmental exposure. For vehicles frequently driven in urban environments or coastal regions, this durability is crucial to avoid rust-raelated failures.

The importance of precise sheet metal replacement parts like Lifan Parts becomes even more evident in the context of modern vehicle design. As cars adopt lightweight materials and tighter engineering tolerances, any deviation from original specifications can affect performance and safety. Accurate reproduction of the original body dimensions ensures the car maintains proper aerodynamics and energy distribution in case of impact. These parts allow repair professionals to deliver results that maintain the same structural integrity as factory-assembled vehicles.

From a long-term maintenance perspective, using high-quality Lifan Parts helps extend a vehicle’s life while maintaining its resale value. Corrosion-resistant materials, advanced surface finishes, and proper fitment reduce the likelihood of secondary damage or accelerated wear. For vehicle owners, this translates into fewer future repairs and consistent performance over time. Workshops that use trusted Lifan Parts also enhance their credibility, offering clients the assurance of safety and reliability long after the repair is completed.

In the field of automotive repair, Lifan Parts play a crucial role in ensuring durability, precision, and efficiency. As advanced sheet metal replacement parts, they help maintain structural integrity, prevent corrosion, and provide accurate fitment for a wide range of Lifan vehicle models. Their high-quality design supports faster repairs, lower maintenance costs, and improved vehicle longevity, making them a reliable solution for workshops and professionals focused on quality-driven automotive restoration and maintenance.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体