Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Byd Parts Manufacturers and Custom Byd Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

News Center

Pay Attention To Our Latest News And Exhibitions

Byd Parts Industry knowledge

The custom design and engineering process plays a crucial role in delivering high-performance, tailored BYD parts. Jiangsu Juncheng Vehicle Industry Co., Ltd. brings its vast experience in automotive design to every aspect of creating custom parts for BYD vehicles. From the outset of the design process, our engineering team collaborates directly with BYD’s engineers to understand the specific functional, aesthetic, and performance needs of the vehicle model. This close collaboration ensures that each part we produce fits perfectly and functions seamlessly within the overall vehicle system. We leverage advanced computer-aided design (CAD) and computer-aided engineering (CAE) software to create precise, detailed models for custom parts. These tools allow us to simulate real-world conditions, enabling us to predict how the parts will behave under stress, temperature changes, and other operating conditions. For example, with the increasing demand for electric vehicles (EVs), Juncheng focuses on creating parts that can withstand high torque, thermal fluctuations, and electrical stresses—common challenges for EV systems. Beyond the mechanical design, our engineers also consider the materials used in each component. By selecting the appropriate metals, composites, and plastics, we ensure that the parts are not only lightweight but also durable enough to handle long-term use in BYD’s vehicles. Our focus on advanced design and engineering helps us deliver custom solutions that enhance vehicle performance and contribute to BYD’s overall success in the automotive market.

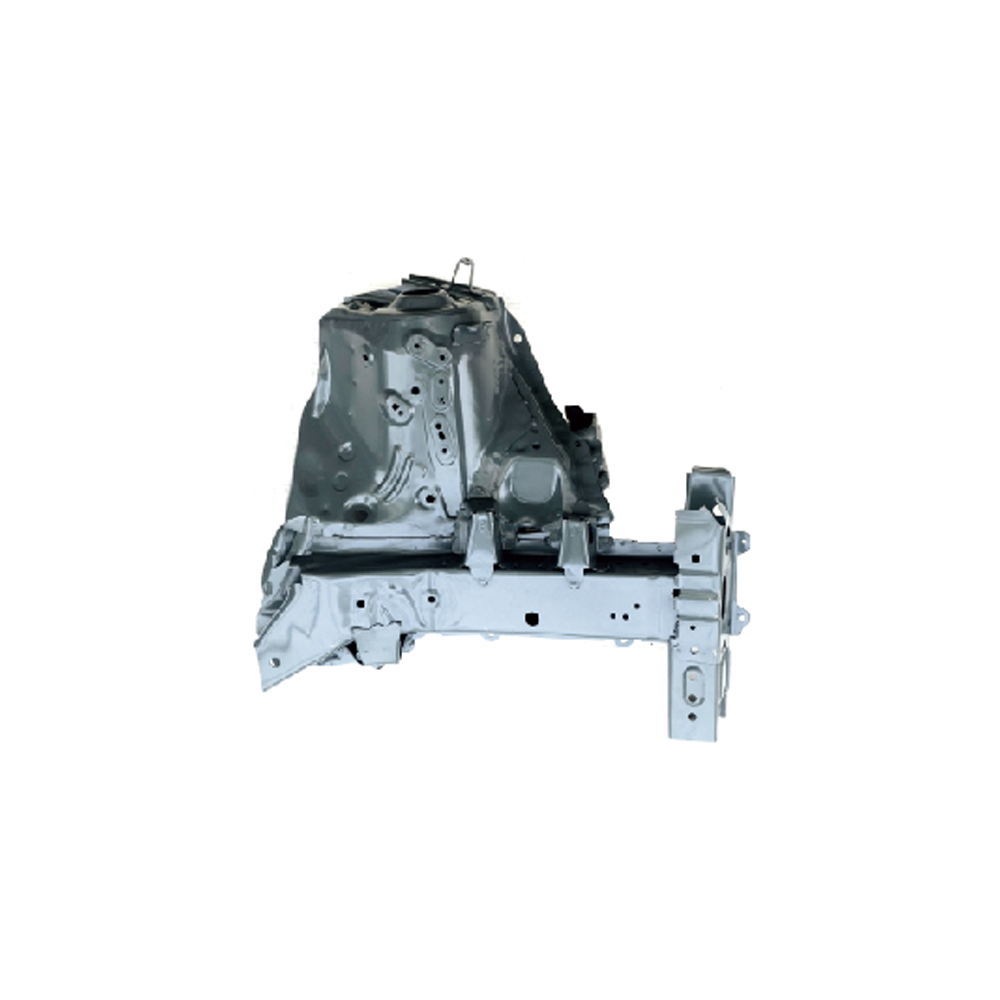

The production of custom BYD parts requires an exceptional level of precision and advanced manufacturing technologies. Jiangsu Juncheng Vehicle Industry Co., Ltd. operates some of the most sophisticated manufacturing facilities in the automotive sector, utilizing cutting-edge processes such as die-casting, CNC machining, stamping, injection molding, and metal forming to create high-quality components for BYD. Die-casting is one of the key techniques we employ for creating intricate metal parts like engine blocks, transmission housings, and structural components. Using high-pressure die-casting, molten metal is injected into custom molds, ensuring the parts are strong, lightweight, and have the precise dimensions required by BYD. This technique allows us to manufacture complex shapes and structures that are critical to vehicle performance. For components requiring the highest level of accuracy, Juncheng uses CNC machining, which offers micron-level precision. This process is perfect for parts such as high-precision brackets, engine components, and suspension elements. The combination of advanced CNC machines and our skilled operators ensures that every part we create meets the strictest quality and design specifications set by BYD. In addition to die-casting and CNC machining, Juncheng also employs stamping for the production of body panels, brackets, and other sheet metal components. The stamping process allows us to form metal into precise shapes that integrate seamlessly into the vehicle’s assembly. For plastic and composite parts, injection molding is used to create complex components with intricate designs. This process ensures that the plastic parts are manufactured with high repeatability and precision, meeting the exact specifications of BYD vehicles.

At Jiangsu Juncheng Vehicle Industry Co., Ltd., quality control is an integral part of our operations. We recognize that custom parts for BYD vehicles must meet the highest standards of performance, safety, and reliability. Our comprehensive quality control system ensures that every custom part we manufacture undergoes rigorous testing and inspection at every stage of production. The process begins with material testing. Before any part is manufactured, we carefully inspect and test the raw materials to ensure they meet the required strength, durability, and corrosion resistance. This step is crucial to ensure that the materials used in custom parts can withstand the demanding conditions they will face in the finished vehicle. Once the parts are produced, Juncheng performs dimensional inspections using advanced coordinate measuring machines (CMMs) to ensure that each part adheres to the specified tolerances. Next, we conduct functional testing on each component. For example, components such as suspension parts, braking systems, and engine components undergo fatigue testing to evaluate their performance over time. This process simulates the stresses that the parts will experience during normal operation and helps us identify potential issues before the parts are delivered to BYD. We also perform environmental testing to assess how the parts perform in different temperatures, humidity levels, and conditions. Components like seals, gaskets, and rubber parts undergo accelerated aging tests to simulate long-term wear and ensure that they will perform reliably throughout the lifespan of the vehicle. This multi-step quality control and testing process is designed to ensure that every custom part we produce for BYD vehicles not only meets but exceeds the expectations of the customer.

Jiangsu Juncheng Vehicle Industry Co., Ltd. understands that effective collaboration is essential when producing custom parts for BYD. From the initial concept stage to the final delivery of parts, we work closely with BYD’s engineering and design teams to ensure that our parts meet the specific requirements of each vehicle model. This collaboration is crucial for ensuring that the custom parts we provide fit perfectly, function optimally, and contribute to the vehicle's overall performance. During the concept phase, our engineers collaborate with BYD’s team to define the key specifications for each part. Whether it's a high-performance suspension component or a lightweight engine part, we work together to identify the materials, design, and manufacturing processes that will best meet the performance, safety, and cost requirements of the vehicle. Once the design is finalized, Juncheng develops prototypes for testing. These prototypes are thoroughly evaluated by BYD’s engineers to ensure that the parts integrate seamlessly with the rest of the vehicle. The feedback we receive from BYD during this phase is invaluable, allowing us to make any necessary adjustments before moving forward with full-scale production. Our commitment to ongoing communication with BYD throughout the production process ensures that any potential issues are addressed quickly, and that the final custom parts meet BYD’s high standards. Juncheng is dedicated to providing the highest-quality parts for BYD, and our collaboration is key to delivering solutions that exceed expectations.

At Jiangsu Juncheng Vehicle Industry Co., Ltd., we offer unmatched expertise and capabilities when it comes to manufacturing custom parts for BYD vehicles. Our years of experience, advanced technology, and commitment to quality set us apart as a trusted partner for BYD in the automotive industry. Our approach to custom parts solutions is driven by a focus on innovation and sustainability. We continuously invest in research and development to ensure that we are incorporating the latest manufacturing technologies and materials into our parts. This allows us to offer cutting-edge solutions that improve the performance, safety, and efficiency of BYD vehicles. We provide scalability in production. Whether BYD needs small batches for limited-edition models or large volumes for mass production, we have the capacity to meet any demand. Our advanced manufacturing facilities and streamlined production processes ensure that we can deliver custom parts on time and within budget. Our global distribution network ensures that custom BYD parts reach any market worldwide. With established logistics partnerships and a strong track record of delivering on time, we make it easier for BYD to maintain consistent production schedules across multiple regions.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体