What are the characteristics of the material selection for sheet metal parts in SEAT Parts?

In the production of SEAT Parts, the material selection for sheet metal parts directly affects the vehicle's safety, durability, lightweight design, and environmental performance. To meet these requirements, SEAT Parts utilizes a variety of high-performance materials to improve overall vehicle performance and optimize cost-effectiveness.

High-Strength Steel (HSS): SEAT Parts extensively uses high-strength steel (HSS) in its body structure, especially in critical areas such as door frames, A-pillars, and B-pillars. High-strength steel provides better structural strength and crash protection while effectively reducing vehicle weight and contributing to improved fuel efficiency.

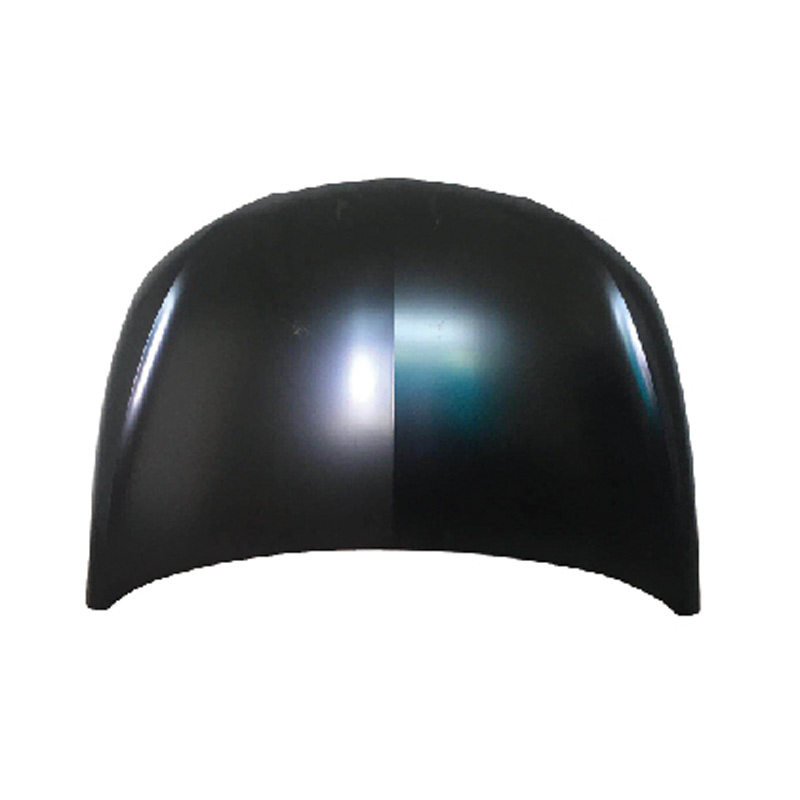

Aluminum Alloy: To further reduce vehicle weight, SEAT Parts uses aluminum alloys in some non-load-bearing components, particularly in parts such as doors, hoods, and roofs. Aluminum alloys are not only lightweight but also have excellent corrosion resistance, making them suitable for use in various climatic conditions.

Galvanized Steel: To enhance corrosion resistance, SEAT Parts utilizes galvanized steel. Galvanized steel effectively prevents corrosion of metal parts in humid environments or prolonged exposure to salt spray, extending the service life of components.

Composite Materials: In some high-end or electric vehicle models, SEAT Parts may also employ composite materials (such as carbon fiber and glass fiber), particularly in exterior trim panels and internal structural components. The use of these materials further reduces vehicle weight while providing excellent rigidity and durability.

SEAT Parts's material selection not only focuses on meeting safety performance but also aims to improve vehicle lightweighting and environmental requirements. Through precise material matching and optimization, SEAT effectively balances cost, strength, weight, and environmental impact in production.

How does SEAT Parts control the precision and quality of sheet metal parts during production?

In SEAT Parts' production process, precision and quality control are crucial to ensuring that each sheet metal part meets stringent standards. To ensure the precision and quality of sheet metal parts, SEAT Parts employs a series of advanced manufacturing technologies and quality management measures:

Precision Die & Automated Production Lines: SEAT Parts utilizes advanced die design and high-precision stamping processes to ensure that each component is manufactured with precision. The use of efficient automated production lines and robotic welding systems not only improves production efficiency but also ensures the dimensional and tolerance accuracy of the produced sheet metal parts.

Advanced Inspection Equipment: SEAT Parts incorporates various advanced quality inspection equipment during production, such as coordinate measuring machines (CMMs), X-ray inspection, and laser scanning measurement. These devices can accurately measure the dimensions, shape, and surface quality of parts, ensuring that each component meets design requirements.

Online Monitoring and Automatic Feedback System: To promptly identify and correct potential production problems, SEAT Parts utilizes an online monitoring system to track quality data at each stage of the production process in real time. Through data collection and automatic feedback, the production line can automatically adjust according to actual conditions, preventing the production of defective products.

Strict Quality Control Processes: At every stage of production, SEAT Parts has strict quality control checkpoints to ensure that all components meet design precision standards after processes such as stamping, welding, and painting. Furthermore, SEAT implements a complete product traceability system, ensuring that every component can be traced and verified at every stage from raw materials to finished product.

These control measures guarantee that SEAT Parts can provide high-precision, high-quality sheet metal parts that meet the stringent standards of the automotive industry, ensuring vehicle performance, reliability, and safety.

What are SEAT Parts' Anti-corrosion Treatment Technologies?

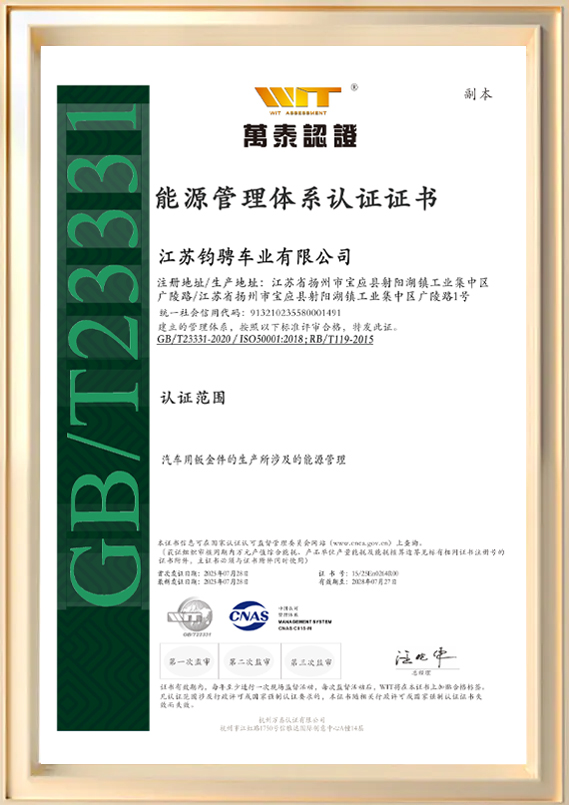

In the production process of SEAT Parts, anti-corrosion treatment is a key step in ensuring the long-term durability of automobiles. To address corrosion issues under different environmental conditions, SEAT Parts employs a variety of advanced anti-corrosion technologies. Jiangsu Juncheng Vehicle Industry Co., Ltd., as a professional supplier of automotive sheet metal parts, provides high-quality sheet metal solutions to global customers, offering valuable insights for SEAT Parts' anti-corrosion technology.

Electrophoretic Coating (EDP): SEAT Parts utilizes electrophoretic coating (EDP) technology, one of the most effective anti-corrosion technologies in the automotive industry. Electrophoretic coating forms a uniform protective film on the metal surface, not only improving corrosion resistance but also enhancing coating adhesion. It is suitable for interior parts of the vehicle body and components frequently exposed to corrosive environments. Jiangsu Juncheng Vehicle Industry Co., Ltd. utilizes similar surface treatment technologies to ensure that its sheet metal parts can withstand various environmental influences, especially in humid and salt spray environments.

Zinc and Aluminum Plating Technologies: To enhance the corrosion resistance of sheet metal parts, SEAT Parts employs galvanizing and aluminizing technologies. These technologies effectively protect vehicle body parts from oxidation, particularly in coastal areas or during winter use, preventing corrosion from salt water. Jiangsu Juncheng Vehicle Industry Co., Ltd. also applies galvanizing technology in its production process, especially when supplying sheet metal parts to globally renowned automotive brands such as Ford and Toyota, where rigorous anti-corrosion treatments enhance the quality and reliability of the parts.

Hot-Dip Galvanizing: In addition to electrophoretic coating, SEAT Parts also employs hot-dip galvanizing technology. This technology involves immersing the sheet metal parts in molten zinc, forming a uniform zinc coating on the surface, providing enhanced corrosion resistance. For Jiangsu Juncheng Vehicle Industry Co., Ltd., this technology is also widely used in the body panels it produces for brands such as Toyota, ensuring that components maintain excellent performance over a long period under various climatic conditions.

Anti-corrosion coatings and sealants: SEAT Parts also uses a variety of anti-corrosion coatings and sealants, especially in body seams and hard-to-reach areas, providing extra protection against corrosion. Jiangsu Juncheng Vehicle Industry Co., Ltd. employs similar anti-corrosion treatment technologies in its production process, ensuring that it provides customers with high-quality, low-maintenance body panels.

Customized anti-corrosion treatment: Based on different market demands and regional environments, SEAT Parts offers customized anti-corrosion treatment solutions. For example, in areas with severe rainy, humid, or maritime climates, SEAT provides special anti-corrosion treatments for its vehicles to ensure long-term durability and low maintenance requirements. Jiangsu Juncheng Vehicle Industry Co., Ltd., when supplying sheet metal parts to global customers, flexibly adjusts its anti-corrosion treatment processes according to the environmental requirements of different markets to ensure that the quality of its parts meets global standards.

Through these advanced anti-corrosion technologies, SEAT Parts can ensure that its sheet metal parts maintain good appearance and performance under different climatic conditions, while reducing corrosion damage during long-term use. Similarly, as a global automotive parts supplier, Jiangsu Juncheng Vehicle Industry Co., Ltd. also applies these advanced anti-corrosion technologies in the production of sheet metal parts, not only meeting the needs of domestic customers but also continuously expanding into international markets. Especially when supplying sheet metal parts for brands such as Ford and Toyota, it ensures that quality and innovation go hand in hand, providing high-quality parts solutions to global customers.

These anti-corrosion technologies ensure the durability of automotive parts produced by SEAT Parts and Jiangsu Juncheng Vehicle Industry Co., Ltd., enhancing not only the long-term performance of vehicles but also the global competitiveness of the brands.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体