What Special Materials Are Used in Porsche Parts' High-Performance Body Components?

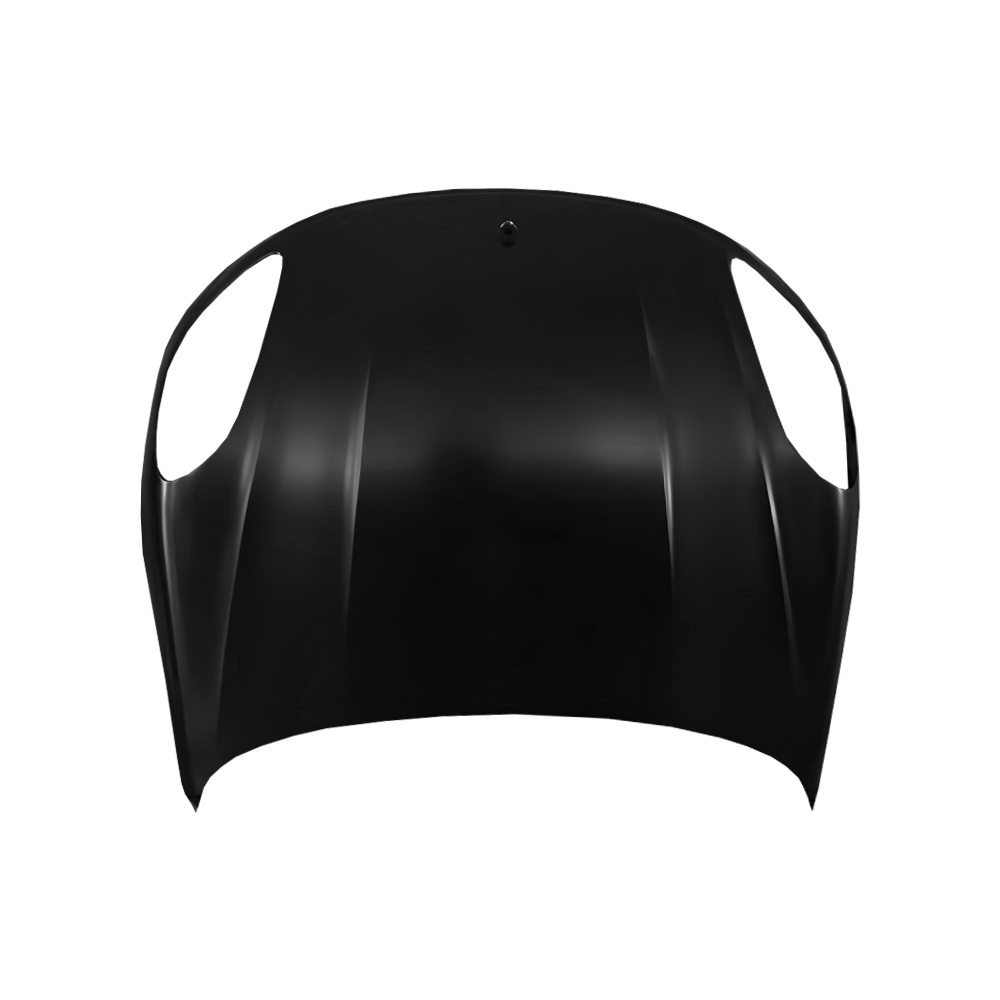

Porsche Parts employs a variety of special materials in the design and manufacture of its high-performance body components (such as doors, hoods, and fenders) to achieve a balance between lightweighting, strength, and crash safety. Here are some common special materials:

Aluminum Alloys: Aluminum alloys are a common material in many Porsche Parts high-performance models, especially in the body and suspension systems. Aluminum alloys not only have excellent corrosion resistance, but their low density also helps reduce body weight, improving the car's power and handling performance. Particularly in sports cars like the Porsche 911, aluminum alloys are frequently used in doors, hoods, roofs, and fenders to ensure that weight reduction is not compromised on strength.

Carbon Fiber Reinforced Polymer (CFRP): For higher-end Porsche Parts (such as the Porsche 918 Spyder and Porsche 911 Turbo S), Porsche utilizes carbon fiber reinforced polymer (CFRP) to further reduce weight. Carbon fiber is not only lighter than aluminum alloys but also possesses extremely high tensile strength and rigidity, making it widely used in body structural components such as the roof, hood, and seats. Through this material, Porsche can significantly improve acceleration performance and handling stability while maintaining extremely high structural strength.

Magnesium Alloy: Magnesium alloys are also an important material choice in some limited-edition or racing versions of Porsche Parts. Magnesium alloys are lighter than aluminum alloys and can effectively reduce body weight in high-performance applications while maintaining necessary strength. Particularly in components such as wheels and seat frames, the use of magnesium alloys helps reduce rotational mass, improving the vehicle's acceleration and braking response. Although magnesium alloys are relatively expensive and difficult to process, Porsche has made it possible in the high-performance field through advanced manufacturing technologies.

High-strength steel: Porsche Parts also uses high-strength steel for components crucial to crash safety and body structural strength. This steel not only provides extremely high impact resistance but also maintains a reasonable weight level. Especially in key structural areas such as the body frame, A-pillar, and B-pillar, Porsche ensures excellent safety and performance by combining high-strength steel with aluminum alloys or carbon fiber.

For high-performance models, are ultra-lightweight materials such as magnesium alloys used to reduce body weight?

For high-performance models, especially racing or limited-edition models such as the Porsche 911 GT3 RS and Porsche 918 Spyder, Porsche Parts prioritizes lightweight design. Reducing body weight not only improves vehicle performance, handling, and braking response, but also increases fuel efficiency (for internal combustion engine vehicles) or extends the driving range of electric vehicles (for electric or hybrid vehicles). To achieve this, Porsche extensively uses ultra-lightweight materials such as magnesium alloys in high-performance body components, specifically:

Magnesium Alloys: Magnesium alloys are used in components of some high-performance models due to their lightweight properties, especially in areas where rotational mass and dynamic performance are critical, such as the Porsche 918 Spyder's wheels and seat frames. Magnesium alloys have a density approximately one-third lower than aluminum, resulting in significant weight reduction and improved acceleration and braking performance. Despite the high processing costs and technical requirements of magnesium alloys, their advantages are significant in Porsche's high-performance and racing vehicle sectors.

Lightweight Body Frame: By using magnesium alloys, Porsche is able to reduce the weight of the body frame without sacrificing vehicle safety. Porsche also uses magnesium alloys in other key body components, such as doors, hoods, and tailgates, further optimizing the vehicle's lightweight effect. In the production of these components, Porsche utilizes precision casting and high-strength magnesium alloy technology to ensure that high performance requirements are met while maintaining body strength and safety.

Wheels and Suspension System: Porsche also uses magnesium alloy wheels in its high-performance models. These wheels not only reduce rotational mass but also improve vehicle handling and stability. Some components in the suspension system may also use magnesium alloys to reduce the weight of the connection between the wheels and the body, thereby improving handling response.

How does Porsche use environmentally friendly materials and recycle them in the manufacturing of parts?

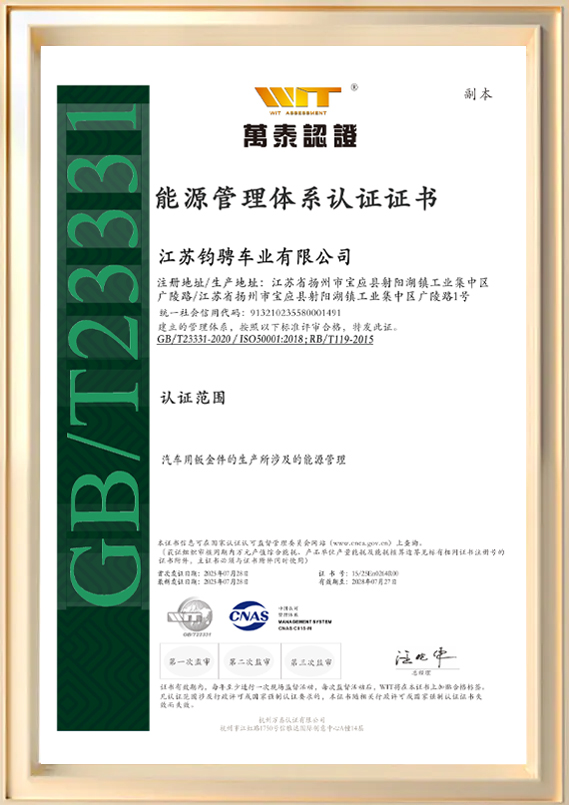

Porsche consistently adheres to the use of environmentally friendly materials in the manufacture of high-performance parts and is committed to the recycling and reuse of these materials. With increasing environmental awareness, Porsche not only uses environmentally friendly materials in its design and production processes but also actively participates in broader sustainable development strategies, driving the industry's transformation towards green production. Based on the production practices of Jiangsu Juncheng Vehicle Industry Co., Ltd., we can see how efficient management of material recycling and environmental protection is achieved in the automotive parts manufacturing process.

Selection and Application of Environmentally Friendly Materials: When designing Porsche Parts, Porsche prioritizes materials with high recyclability. For example, basic materials such as aluminum alloys and steel not only have excellent strength and corrosion resistance but also have high resource utilization rates during recycling. Similar environmental principles are implemented in the production processes of Jiangsu Juncheng Vehicle Industry Co., Ltd., particularly in the production of metal sheet metal parts (such as exterior body panels, doors, and hoods). The aluminum alloys and steel used meet high recyclability requirements and can be effectively recycled at the end of the product's life cycle. This material selection not only helps reduce environmental pollution but also supports Porsche in achieving efficient resource management and lower manufacturing costs.

Use of environmentally friendly coatings and processes: Porsche Parts** also employs environmentally friendly coating technologies, such as water-based paints and low-VOC (volatile organic compound) paints, to reduce the emission of harmful substances. These coatings not only meet environmental standards but also effectively improve the durability and corrosion resistance of parts. Jiangsu Juncheng Vehicle Industry Co., Ltd. also adopts similar environmentally friendly processes in its mold production and sheet metal manufacturing, achieving a low-pollution, low-energy production mode through automated painting production lines, further reducing the negative environmental impact of the production process.

Material recycling and reuse: Porsche places great emphasis on material recycling and reuse during the production process. For example, scrap aluminum alloys and steel can be recycled, reducing the demand for raw materials and minimizing resource waste. In its electrification process, Porsche also prioritizes battery recycling, employing advanced battery recycling technologies to extract and reuse precious metals such as lithium, cobalt, and nickel, reducing environmental impact. This is similar to the approach taken by Jiangsu Juncheng Vehicle Industry Co., Ltd. in sheet metal production. Through flexible production processes and mold customization capabilities, Jiangsu Juncheng Vehicle Industry Co., Ltd. effectively handles metal scrap, achieving efficient resource recycling and reuse.

Flexible Customization and Environmental Strategy: Leveraging its core technological advantages in its mold factory, Jiangsu Juncheng Vehicle Industry Co., Ltd. not only achieves efficient production of automotive parts but also provides highly customized services to meet the needs of diverse clients. Regarding the application of environmentally friendly materials, Jiangsu Juncheng Vehicle Industry Co., Ltd. can provide customized metal sheet metal parts that meet environmental standards according to customer requirements, while ensuring minimal waste during production and ensuring compliance with environmental protection requirements at every stage through a rigorous quality management system. Similar practices are reflected in the production of Porsche Parts, especially in customized models and high-performance versions. Porsche can customize and produce high-performance parts that meet environmental standards and technical requirements.

Sustainable production and eco-design philosophy: Porsche applies Life Cycle Assessment (LCA) to evaluate the environmental impact of each component during the production process, from design and manufacturing to use and recycling, ensuring that the environmental burden is minimized throughout the product's lifecycle. Jiangsu Juncheng Vehicle Industry Co., Ltd. also emphasizes green manufacturing and eco-design in its sheet metal parts production process, reducing its environmental impact by optimizing processes and using environmentally friendly raw materials. Both companies' efforts in promoting environmentally friendly materials and green manufacturing are complementary, reflecting the global automotive industry's shared pursuit of sustainable development.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)