How Do Jaguar Parts Redefine the Quality Standards of Modern Automotive Metal Body Components?

The continuous evolution of the automotive repair and maintenance industry has led to growing expectations for precision, durability, and aesthetics in replacement body parts. Among the many categories in this field, Jaguar Parts represent an advanced approach to metal sheet components—where structural strength meets refined craftsmanship. These metal replacement parts are not simply substitutes; they are engineered to restore a vehicle’s integrity and style while ensuring reliable performance over time.

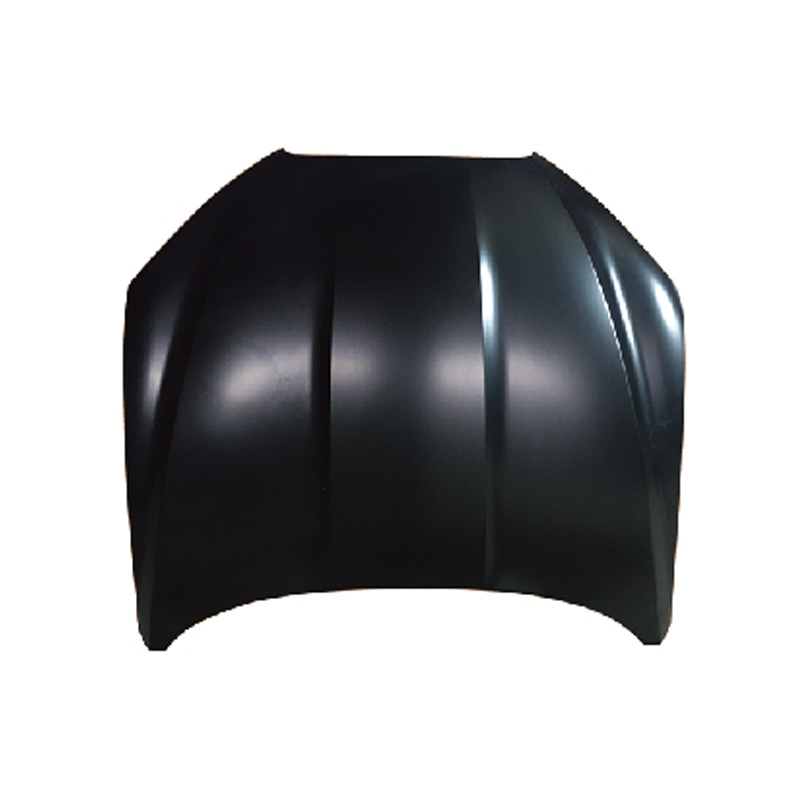

High-quality metal replacement parts are essential in maintaining the safety and performance of any vehicle. Whether replacing a hood, fender, or door, each piece must achieve perfect alignment and dimensional accuracy with the original structure. The Jaguar Parts series demonstrates how modern metalworking and surface treatment technologies elevate these components beyond conventional standards. Every panel is designed to deliver a balance between rigidity and weight, maintaining vehicle stability without adding unnecessary mass.

In the production process, manufacturers employ advanced stamping and forming techniques that allow for precise curvature and consistent thickness across each metal panel. This precision minimizes gaps during installation, ensuring an OEM-level fit that improves aerodynamics and noise insulation. Furthermore, corrosion resistance plays a decisive role—especially in regions exposed to humidity, road salt, or temperature fluctuations. The application of electrostatic coatings, anti-rust primers, and galvanization treatments helps Jaguar Parts achieve exceptional surface protection, extending their service life significantly.

Beyond functionality, aesthetics are another critical aspect. High-end models often feature sleek body lines and refined contours that must be preserved during restoration or repair. Each replacement part, from the hood to the rear fender, is crafted to match the vehicle’s original curvature and surface texture. This ensures seamless visual consistency after repainting and reassembly, maintaining the car’s sophisticated appearance. These details reflect the high expectations of customers who demand not only technical precision but also aesthetic perfection.

Why Are Jaguar Parts Considered a Benchmark in Metal Replacement Part Manufacturing?

When examining the manufacturing of Jaguar Parts, it becomes evident that their excellence is rooted in a deep understanding of material science, precision engineering, and performance testing. In today’s competitive aftermarket, producing sheet metal components is no longer about simple duplication—it’s about engineering a replacement that performs on par with or better than the original.

To achieve this, manufacturers start with high-grade steel or aluminum alloys that undergo strict quality control. These materials are chosen for their ideal balance of tensile strength, ductility, and resistance to deformation. Advanced heat treatment processes further enhance the mechanical properties, preventing warping during forming and welding. This meticulous approach ensures that Jaguar Parts maintain structural integrity even under high stress or impact conditions, such as during minor collisions or long-term vibration exposure.

In addition, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software ensures that each panel follows the exact geometry of the original body structure. Dimensional data is collected using 3D scanning and laser measurement, allowing for tolerance control within fractions of a millimeter. As a result, the parts offer superior fitment accuracy, reducing installation time and eliminating the need for manual adjustments during assembly.

The surface treatment and finishing processes also represent a major step forward. Powder coating and electrophoretic deposition (E-coating) provide uniform coverage, excellent adhesion, and resistance against corrosion and UV damage. These coatings form a protective layer that significantly increases longevity while maintaining a smooth, paint-ready surface. Such characteristics make Jaguar Parts a preferred choice in professional auto body workshops where reliability and finish quality are paramount.

Another key advantage lies in the testing and validation process. Before being approved for sale, each component undergoes a series of mechanical, environmental, and durability tests. These include tensile testing, salt spray corrosion testing, and impact resistance evaluation. By meeting or exceeding OEM benchmarks, Jaguar Parts ensure consistent performance across diverse road and climate conditions. This level of reliability not only enhances safety but also contributes to reduced maintenance costs over time.

The broader significance of Jaguar Parts extends to their role in supporting sustainable repair practices. Instead of discarding entire body assemblies, vehicle owners can replace only the damaged sections, minimizing waste and resource consumption. Furthermore, many modern manufacturers are adopting eco-friendly production techniques—such as recyclable materials and energy-efficient coating systems—to align with global environmental goals. This demonstrates how the metal replacement parts industry continues to evolve toward greener and more efficient manufacturing standards.

What Technical Advantages Make Jaguar Parts Stand Out in Vehicle Restoration and Repair?

When it comes to vehicle restoration, structural integrity and precision are the two most crucial factors determining the quality of a repair. Jaguar Parts distinguish themselves through their advanced manufacturing process and the superior mechanical properties of the materials used. Each component—whether a hood, door, or fender—is not only a visual match but also a structural equivalent to the original factory-installed part.

Precision in Dimensional Engineering:

The defining feature of Jaguar Parts lies in their precise engineering. Every panel is developed using digital modeling and measured through 3D scanning to ensure accurate curvature and alignment. This dimensional accuracy allows technicians to install the components with minimal adjustment, achieving a seamless fit with the surrounding body structure. Proper alignment ensures uniform stress distribution across the vehicle’s frame, preventing deformation and ensuring long-term durability.

Such precision also enhances efficiency in repair operations. With Jaguar Parts, workshops can significantly reduce the time required for fitting and alignment, as each piece is engineered to match the original body’s geometry. This not only improves productivity but also minimizes the need for additional modifications or adjustments, ensuring consistency across multiple installations.

Strength, Safety, and Impact Resistance:

The safety and strength of Jaguar Parts are the result of advanced material selection and rigorous testing. The sheet metal used in these components undergoes controlled heat treatment to enhance its tensile strength and resistance to impact. This ensures that in the event of a collision, the parts absorb and distribute energy efficiently—protecting the overall body structure of the vehicle.

Additionally, special attention is given to the reinforcement zones of each part, such as door edges and fender corners, where the likelihood of impact is higher. By optimizing metal thickness and forming angles, these components maintain their rigidity even after prolonged exposure to vibration or temperature variations. Such structural reinforcement not only contributes to safety but also extends the part’s service life under demanding conditions.

Surface Protection and Long-Term Performance:

Another key aspect of Jaguar Parts is the advanced surface treatment applied during manufacturing. The metal panels undergo a multi-stage anti-corrosion process, which includes cleaning, phosphating, electrophoretic coating, and powder finishing. These layers act as a shield against rust, oxidation, and environmental degradation. The result is a smooth and durable surface that remains resistant to moisture, chemicals, and road salt.

This surface preparation also ensures optimal paint adhesion during final finishing. Whether the part is repainted to match the vehicle’s color or left in a primer state, the coating maintains uniform texture and gloss. For repair centers and end users, this translates to a more professional and lasting restoration outcome—one that meets both visual and functional expectations.

Value in Professional Repair and Maintenance:

In the professional repair industry, using high-quality replacement components such as Jaguar Parts brings measurable advantages. These include improved assembly efficiency, reduced rework rates, and enhanced vehicle resale value. Since the components adhere strictly to OEM specifications, they ensure that the repaired vehicle maintains its original performance and appearance. For car owners, this means peace of mind knowing their vehicle remains structurally sound and aesthetically consistent after repairs.

Moreover, the interchangeability of these parts allows workshops to manage inventory more effectively. With standardized mounting points and precise alignment, technicians can replace panels without complex adaptation work, reducing downtime and improving customer satisfaction. This efficiency not only benefits repair businesses but also underscores the growing importance of precision-manufactured sheet metal components in the modern automotive service industry.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体