How Do ALFA Parts Redefine Quality Standards in Automotive Metal Body Replacement Components?

In the automotive repair and manufacturing industry, ALFA Parts represent a benchmark for precision, durability, and consistency in the field of metal sheet replacement components. These parts are not simply accessories used to restore a car’s appearance; they are vital elements that maintain vehicle integrity, safety, and long-term performance after wear or impact.

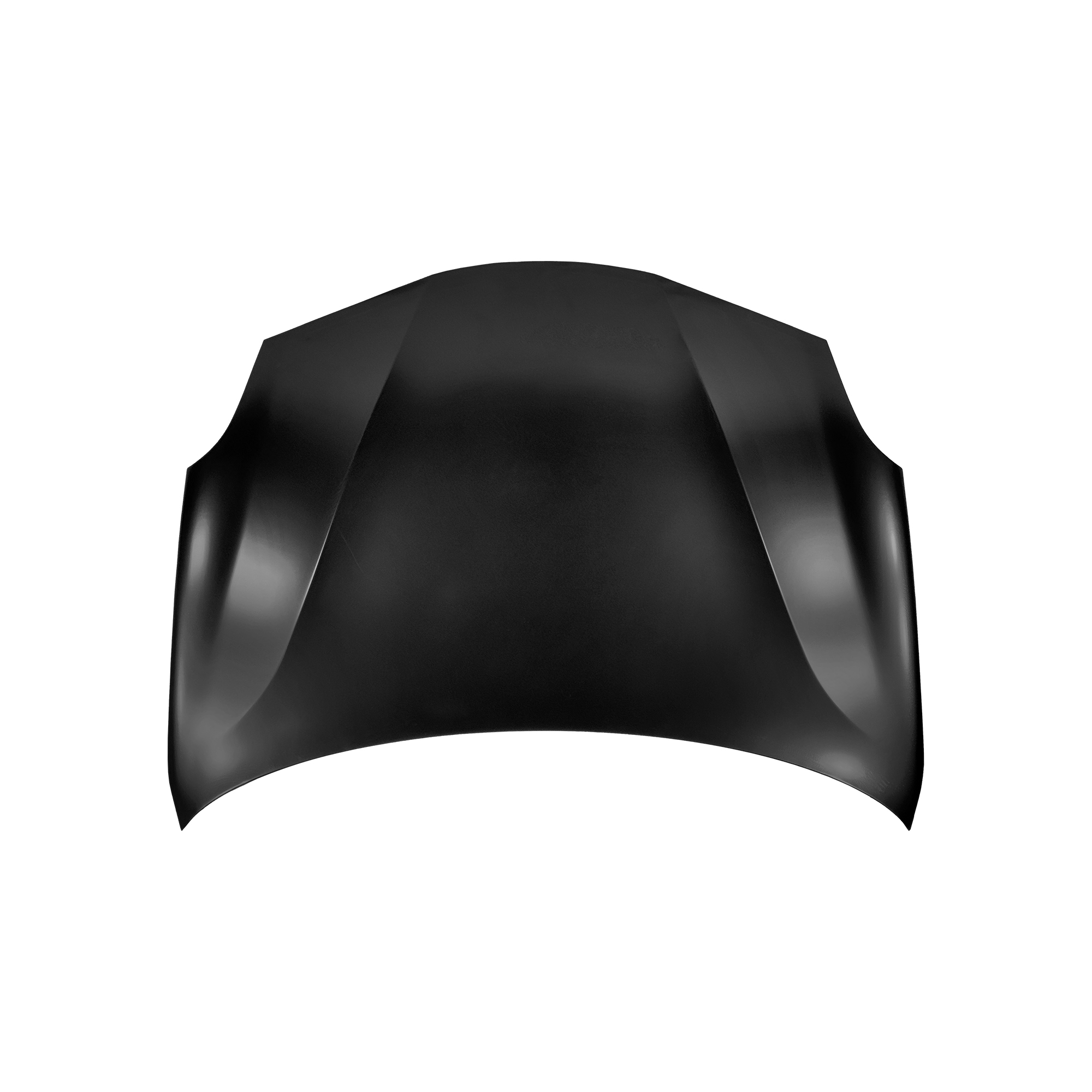

Modern automotive design emphasizes both lightweight structure and high safety performance. To meet these needs, manufacturers of ALFA Parts focus on advanced engineering, material optimization, and precision manufacturing. Every fender, door, or bumper produced under this category undergoes detailed design and analysis to ensure compatibility with the original vehicle structure while enhancing resistance to corrosion and mechanical stress.

The use of high-strength alloy steel is central to the quality of ALFA Parts. This material provides excellent tensile strength, impact absorption, and fatigue resistance while remaining relatively light. Each panel is shaped using precision stamping technology to achieve dimensional accuracy that matches the vehicle’s original specifications. This allows for seamless installation and a factory-level appearance after repair or replacement.

Production involves not only mechanical forming but also meticulous surface treatment and coating. Anti-corrosion layers, often zinc or polymer-based, protect the metal from rust and environmental degradation. These treatments are especially valuable for vehicles operating in humid, coastal, or high-salt environments, where corrosion is a major concern.

Quality assurance plays a crucial role throughout every stage of ALFA Parts manufacturing. Before leaving the factory, each part undergoes dimensional measurement, structural testing, and surface inspection. The aim is to ensure that the final product meets both safety standards and aesthetic expectations. This approach provides automotive workshops and distributors with reliable, ready-to-install components that reduce repair time and improve efficiency.

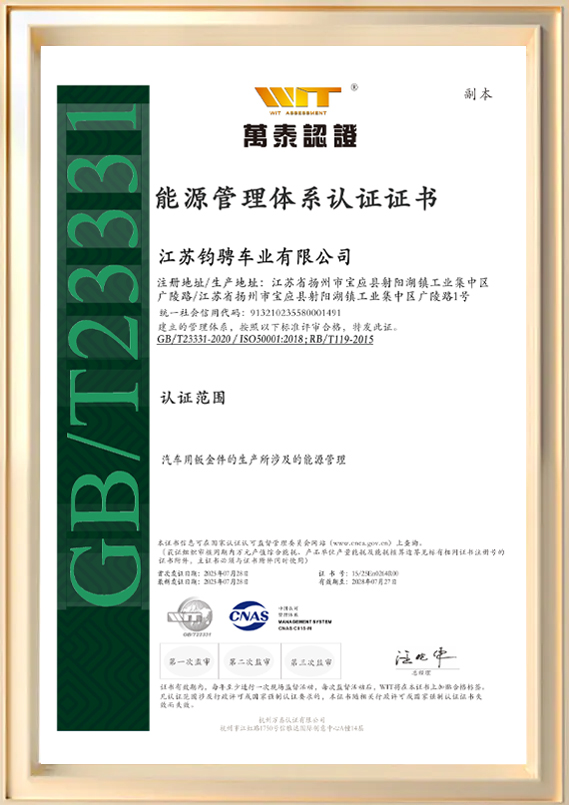

From a sustainability perspective, ALFA Parts also reflect the growing global emphasis on eco-friendly production. Factories engaged in manufacturing these components adopt low-waste processes, energy-efficient machinery, and recyclable materials. The coatings used are designed to minimize harmful emissions while maintaining long-lasting performance. This aligns with the broader automotive trend toward green manufacturing and resource conservation.

Overall, ALFA Parts exemplify how modern engineering principles and quality control systems can elevate the standard of metal replacement parts. Their combination of precision, resilience, and compatibility ensures that vehicles repaired with these components maintain not only their appearance but also their structural safety. In an industry where every millimeter of fit matters, ALFA Parts stand as a symbol of technological reliability and professional craftsmanship.

What Role Do ALFA Parts Play in the Evolution of Automotive Sheet Metal Manufacturing?

The production of automotive sheet metal components has undergone significant technological evolution, and ALFA Parts are a strong example of this progress. The process involves much more than forming metal sheets; it requires precise control of material properties, advanced tooling design, and automated production systems that ensure repeatable quality.

At the initial stage, engineers use 3D modeling and simulation tools to predict how each sheet metal component will behave under real-world stress conditions. This digital approach allows optimization of material thickness, bending angles, and stress distribution before the physical production process begins. It reduces waste, improves consistency, and ensures that each ALFA Part achieves the desired strength without unnecessary weight.

During fabrication, automated stamping lines and CNC-controlled presses form alloy steel sheets into precise shapes. These technologies maintain consistent force distribution and prevent deformation that could affect fit or appearance. Once shaped, the components undergo surface cleaning, coating, and finishing. These steps improve paint adhesion, corrosion resistance, and overall surface uniformity, which is critical for achieving a professional final look during vehicle assembly or repair.

Another defining feature of ALFA Parts manufacturing is the balance between rigidity and lightness. Excessive material thickness can increase strength but also adds unnecessary mass, which negatively affects vehicle performance and fuel efficiency. To overcome this, advanced alloy compositions and optimized geometries are used to maintain high structural integrity while keeping the panels lightweight. This approach supports modern automotive trends toward efficiency and performance balance.

Quality assurance extends beyond basic visual checks. Each ALFA Part is subjected to impact testing, tensile strength evaluation, and corrosion simulation. These rigorous procedures ensure that the parts can perform effectively even under demanding conditions. The manufacturing standards applied here mirror those found in original equipment (OE) production, making ALFA Parts a dependable choice for professional repair facilities worldwide.

Surface finish is another critical indicator of manufacturing excellence. ALFA Parts are known for their smooth texture and even coating, which prevent paint defects and ensure long-term durability. A well-finished surface also improves the visual continuity of the vehicle after repair, preserving the value and aesthetic appeal of the car.

The global automotive aftermarket increasingly demands components that are both cost-effective and reliable. Manufacturers specializing in metal sheet replacement parts contribute to this goal by providing high-quality alternatives to original manufacturer components. ALFA Parts play a central role in this transformation by offering precision-engineered products that meet the same functional standards as OE parts but at more competitive prices.

Technological innovation continues to drive improvements in sheet metal production. Many modern factories that produce ALFA Parts now employ robotic welding, laser cutting, and automated inspection systems. These technologies not only enhance production speed and accuracy but also reduce human error and operational costs. Real-time data monitoring ensures consistent quality across large production runs, creating a stable supply of reliable components for global markets.

Looking ahead, as the automotive industry embraces electric and hybrid technologies, the demand for lightweight yet durable metal components will continue to increase. ALFA Parts are already aligned with this direction, utilizing advanced materials and design methods that ensure compatibility with the next generation of vehicles.

In summary, ALFA Parts represent more than just replacement body components. They embody a philosophy of precision manufacturing, environmental responsibility, and continuous innovation. By combining high-strength materials with advanced forming and coating technologies, they deliver long-lasting performance and a perfect fit for various vehicle types. For distributors, workshops, and end-users, they provide a dependable solution that enhances both efficiency and product quality in automotive repair and production.

Through consistent attention to detail, strict quality control, and sustainable manufacturing practices, ALFA Parts have established themselves as a trusted choice in the global market for metal sheet replacement parts. They illustrate how industrial excellence and advanced engineering can come together to shape the future of automotive body manufacturing.

How Do ALFA Parts Enhance Repair Efficiency and Practical Vehicle Maintenance?

Beyond material strength and manufacturing precision, ALFA Parts provide significant advantages in practical vehicle repair and maintenance operations. The design and production of these sheet metal replacement components focus on installation ease, functional compatibility, and long-term durability, which are essential for efficient workshop operations and high-quality vehicle restoration.

One of the primary benefits of using ALFA Parts is the high level of dimensional accuracy achieved during production. Every door, fender, and bumper is engineered to match the original vehicle geometry precisely. This means that technicians can install the parts with minimal adjustment, reducing labor time and avoiding common issues such as misalignment, uneven panel gaps, or stress points.

The standardized mounting points and pre-drilled attachment holes further simplify the installation process. Whether working on compact city vehicles or larger SUVs, repair professionals can fit the panels directly onto the chassis without modifying the mounting structure. This efficiency translates into faster turnaround times for repairs, lower labor costs, and a higher consistency of results across multiple installations.

ALFA Parts are designed to serve a wide range of vehicles, from high-performance coupes to larger family SUVs. Their adaptability allows repair facilities to maintain a streamlined inventory without sacrificing coverage for different models. For smaller cars, the panels maintain lightweight construction while providing sufficient rigidity and impact resistance. For larger vehicles, reinforcement zones and optimized thickness ensure that the parts can withstand higher loads and stress without deformation.

This versatility also enables ALFA Parts to be used for both routine maintenance and post-accident repairs. Minor scratches, dents, or rust-damaged panels can be replaced efficiently, restoring the vehicle to its original condition. In accident scenarios, the high-strength alloy steel and precise fit of ALFA Parts help maintain structural integrity and safety performance, protecting occupants and preserving the chassis alignment.

The benefits of ALFA Parts extend beyond immediate repair efficiency. The combination of corrosion-resistant alloys and advanced surface coatings ensures that each panel withstands environmental factors such as moisture, road salts, and UV exposure. This longevity reduces the likelihood of future repairs and maintains the vehicle’s resale value by preserving its original appearance and structural integrity.

For commercial fleets and service centers, this reliability translates into lower maintenance costs over the vehicle’s lifespan. Consistent part quality and standardized design also simplify inventory management, allowing distributors and workshops to maintain an efficient stock of replacement components without sacrificing quality or coverage.

By minimizing installation errors and ensuring consistent part performance, ALFA Parts enhance overall workshop productivity. Technicians can complete repairs faster, reducing vehicle downtime for customers. The predictable fit and surface finish also reduce the need for corrective adjustments or repainting, allowing workshops to allocate resources more effectively and handle higher repair volumes without compromising quality.

In practice, this combination of precision, reliability, and adaptability positions ALFA Parts as a vital resource in professional automotive repair. They serve not only as replacement components but also as tools for operational efficiency, safety assurance, and long-term vehicle maintenance.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体