How Do LYNK-CO Parts Ensure Vehicle Safety Through Precision Sheet Metal Replacement?

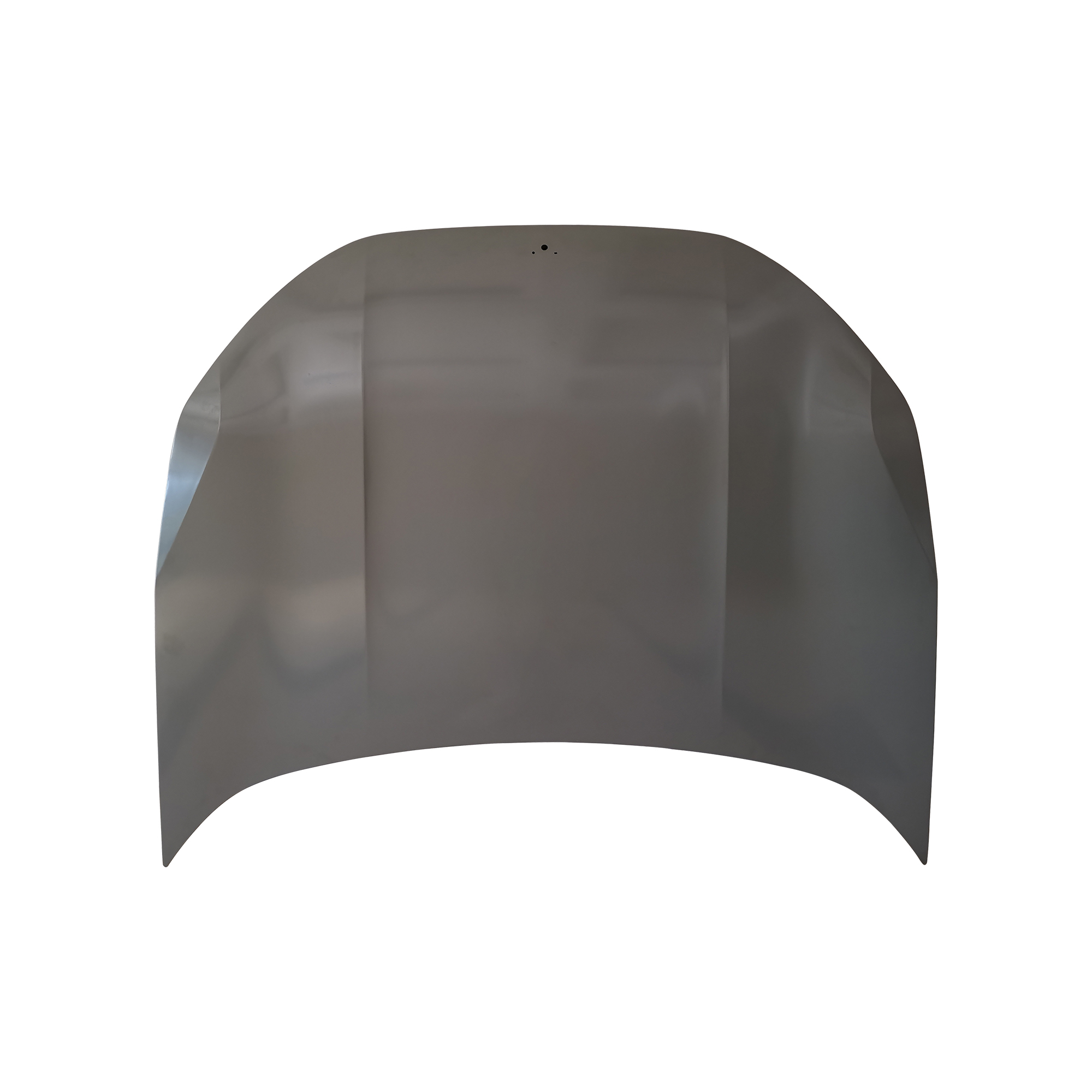

The structural integrity of a vehicle is central to safety performance. LYNK-CO Parts provide high-strength sheet metal replacement parts designed to maintain the vehicle’s original framework after collisions or wear. Components such as doors, hoods, fenders, and trunk lids are manufactured to exact specifications, ensuring each part fits seamlessly with the existing structure. Accurate alignment preserves the designed energy absorption areas and crumple zones, reducing the risk of injury in accidents.

The choice of robust metal materials in LYNK-CO Parts allows panels to withstand external impacts and repeated stress without deformation. This quality is essential for vehicles operating in diverse conditions, from busy urban streets to high-speed highways. Replacement parts that meet or exceed original material standards support passive safety systems, ensuring passengers remain protected during unforeseen events.

Each component is engineered to replicate the vehicle's original design. Proper fitment reduces uneven stress on connected panels, preventing long-term structural issues. The precision of these parts also contributes to handling stability, keeping the vehicle responsive and predictable in various driving situations. Vehicle performance is maintained alongside safety, reflecting the importance of high-quality metal replacement in automotive repair.

The durability of LYNK-CO Parts extends to resistance against corrosion and mechanical fatigue. Panels retain their protective properties over years of use, even in challenging climates or under heavy road exposure. This consistency ensures the body structure remains reliable for long-term use, supporting both routine maintenance and major restoration projects. Using precise replacement components preserves safety-critical zones and enhances the vehicle’s overall structural integrity.

The integration of LYNK-CO Parts also safeguards the functional lifespan of other vehicle systems. Properly aligned and strong panels protect internal components, including suspension mounts and engine compartments, from undue stress. This protective role reduces the likelihood of cascading failures in related systems, demonstrating how high-quality sheet metal replacements contribute to comprehensive vehicle safety.

In What Ways Do LYNK-CO Parts Streamline Automotive Maintenance and Exterior Restoration?

Efficiency in vehicle repair relies on the compatibility and quality of replacement components. LYNK-CO Parts are engineered for precise fitment, allowing technicians to complete replacements without extensive adjustments. This reduces labor time and minimizes the risk of installation errors that could compromise both appearance and structural performance. A streamlined process supports faster turnaround in workshops while maintaining high repair standards.

Advanced manufacturing methods used in producing these sheet metal replacement parts ensure smooth surfaces and consistent material properties. Components can be painted or coated directly after installation, facilitating aesthetic restoration alongside structural repair. Accurate alignment minimizes gaps and ensures the vehicle maintains its original design style, which is important for both visual consistency and resale value.

The modular design compatibility of LYNK-CO Parts also enhances repair workflow. Components are suitable across multiple vehicle models, which allows workshops to maintain fewer variations in stock while serving a wide range of maintenance needs. Standardized fitment reduces troubleshooting and post-installation adjustments, supporting higher efficiency in repair operations.

Beyond operational speed, using high-precision LYNK-CO Parts reduces material waste and promotes sustainable repair practices. Properly fitting panels require minimal trimming or modification, conserving resources and supporting environmentally conscious maintenance. Workshops benefit from lower costs, reduced labor, and consistent outcomes, demonstrating the practical advantages of reliable sheet metal replacements.

The predictability of these replacement parts also allows technicians to plan and execute complex restoration projects more effectively. Body panels, doors, and hoods align as intended, supporting structural inspections, refinishing, and quality checks without repeated adjustments. By combining durability, fit accuracy, and workflow efficiency, LYNK-CO Parts facilitate repairs that meet both technical and aesthetic expectations.

The use of LYNK-CO Parts also contributes to enhanced workshop productivity. When replacement panels fit precisely, technicians can focus on complementary tasks such as mechanical inspections, alignment checks, or detailing. This reduces downtime between repair stages and allows multiple vehicles to be serviced concurrently. High consistency across batches ensures that every installation meets the same standard, reducing variability and enabling workshops to maintain predictable schedules without compromising quality.

In addition, LYNK-CO Parts improve the reliability of after-sales service. Vehicles repaired with accurately fitting, high-strength sheet metal panels maintain structural integrity and visual appeal over time. This reliability reduces the need for follow-up adjustments or repairs, creating a more seamless experience for vehicle owners. Consistent performance from replacement parts also supports warranty programs and builds trust between service providers and clients, reinforcing the importance of using high-quality sheet metal replacements in professional automotive maintenance.

Why Are Durable LYNK-CO Sheet Metal Replacement Parts Essential for Long-Term Vehicle Reliability?

Longevity and reliability of a vehicle depend on the strength and performance of its body structure. LYNK-CO Parts deliver replacement panels that preserve original vehicle integrity, providing long-term resistance against pressure, impact, and environmental exposure. High-strength materials ensure panels maintain form and function, contributing to safety, performance, and visual consistency over the vehicle’s lifespan.

Precision-engineered sheet metal replacement parts prevent uneven stress distribution that can cause misalignment, rattling, or premature wear of other components. Proper fitment also supports optimal aerodynamics, reduces vibration, and maintains fuel efficiency. Maintaining structural accuracy ensures that the vehicle continues to operate as designed, even after multiple repairs or extensive use.

The corrosion resistance of LYNK-CO Parts plays a vital role in long-term performance. Exposure to moisture, road salts, and urban pollution can degrade standard metal panels over time. High-quality coatings and alloys prevent rust, protect mechanical connections, and maintain overall stability. Reduced need for repeated replacements supports cost-effective ownership and preserves the aesthetic appearance of the vehicle.

Durable metal components also safeguard the integrity of adjacent systems. Panels protect suspension elements, engine mounts, and internal electronics from impact and environmental stress. By ensuring that critical areas remain shielded, LYNK-CO Parts contribute to a reliable, long-lasting vehicle that maintains safety, functionality, and comfort over time.

The consistent performance of these replacement parts underscores their importance in modern automotive repair. Repair professionals can rely on LYNK-CO Parts to deliver precise fit, long-term durability, and high-quality restoration results. By combining structural strength, corrosion resistance, and visual consistency, these sheet metal replacement components ensure vehicles remain safe, reliable, and visually coherent throughout their service life.

The robustness of LYNK-CO Parts also reduces long-term maintenance needs. Panels that retain their shape and resist corrosion minimize the frequency of replacements, protecting vehicle owners from repeated repair costs. This durability ensures that vehicles maintain consistent performance and appearance over years of use, even under challenging road or weather conditions. High-strength replacement components preserve the integrity of the entire body structure, contributing to the reliability and longevity of the vehicle.

In addition, the precision and durability of LYNK-CO Parts support aftermarket upgrades and repairs without compromising vehicle performance. Technicians can confidently integrate these panels into restoration projects, knowing that each part will maintain alignment, structural balance, and safety standards. This reliability allows vehicles to retain their designed driving characteristics and visual appeal, reinforcing the importance of quality sheet metal replacement parts in sustaining long-term vehicle value and operational efficiency.

LYNK-CO Parts provide high-quality sheet metal replacement parts that are essential for modern automotive repair and vehicle restoration. These durable, precision-engineered components offer accurate fitment, impact resistance, and corrosion protection for multiple vehicle models. Their reliable construction ensures long-term safety, maintains vehicle performance, and streamlines installation for repair shops. Choosing LYNK-CO Parts supports efficient maintenance workflows, preserves structural integrity, and restores both aesthetics and functionality, making them a trusted solution for professional automotive body repair.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体