Why Are Jac Parts Considered a Practical Solution for Modern Automotive Repair Needs?

In the automotive repair industry, the demand for durable, precisely engineered, and cost-effective metal replacement parts continues to grow. Jac Parts exemplify this demand by providing high-quality sheet metal components that meet both performance and maintenance needs. Designed for various vehicle types, including sedans, SUVs, pickups, light trucks, and commercial vehicles, these parts represent the balance between structural strength, material innovation, and repair efficiency.

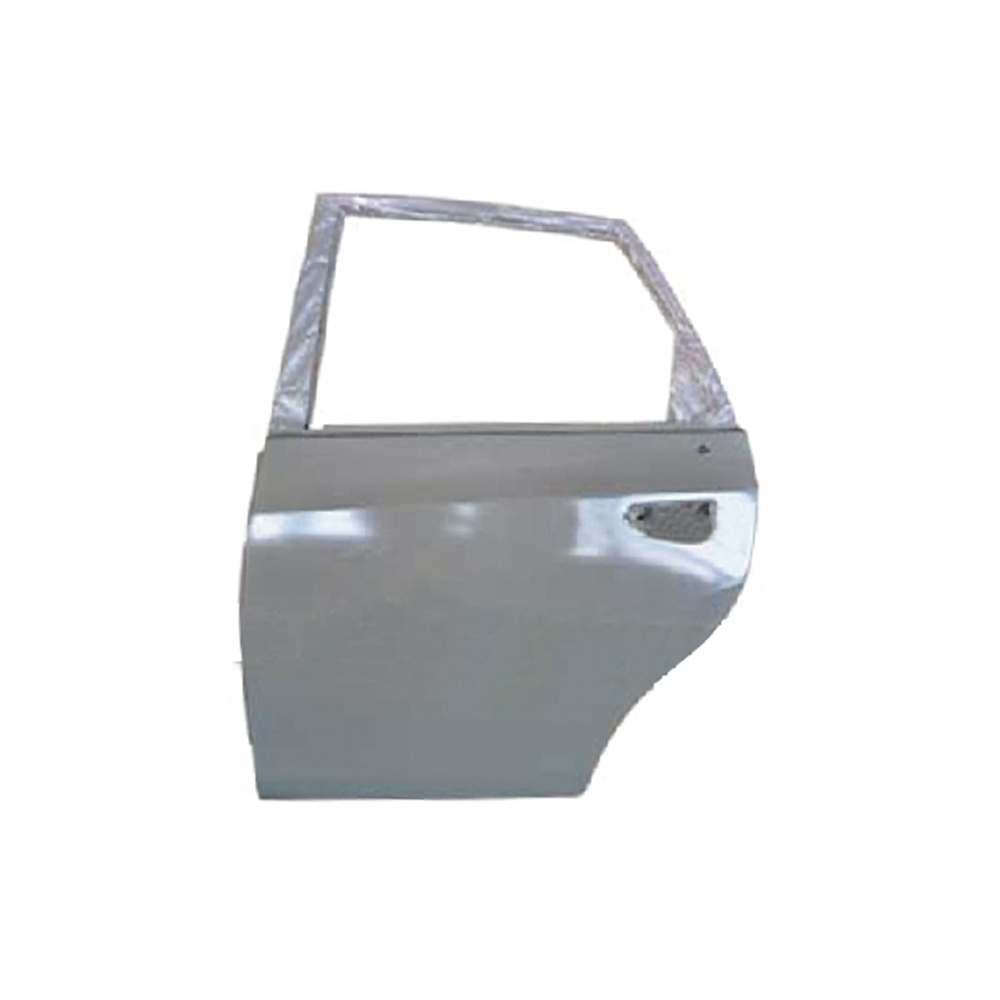

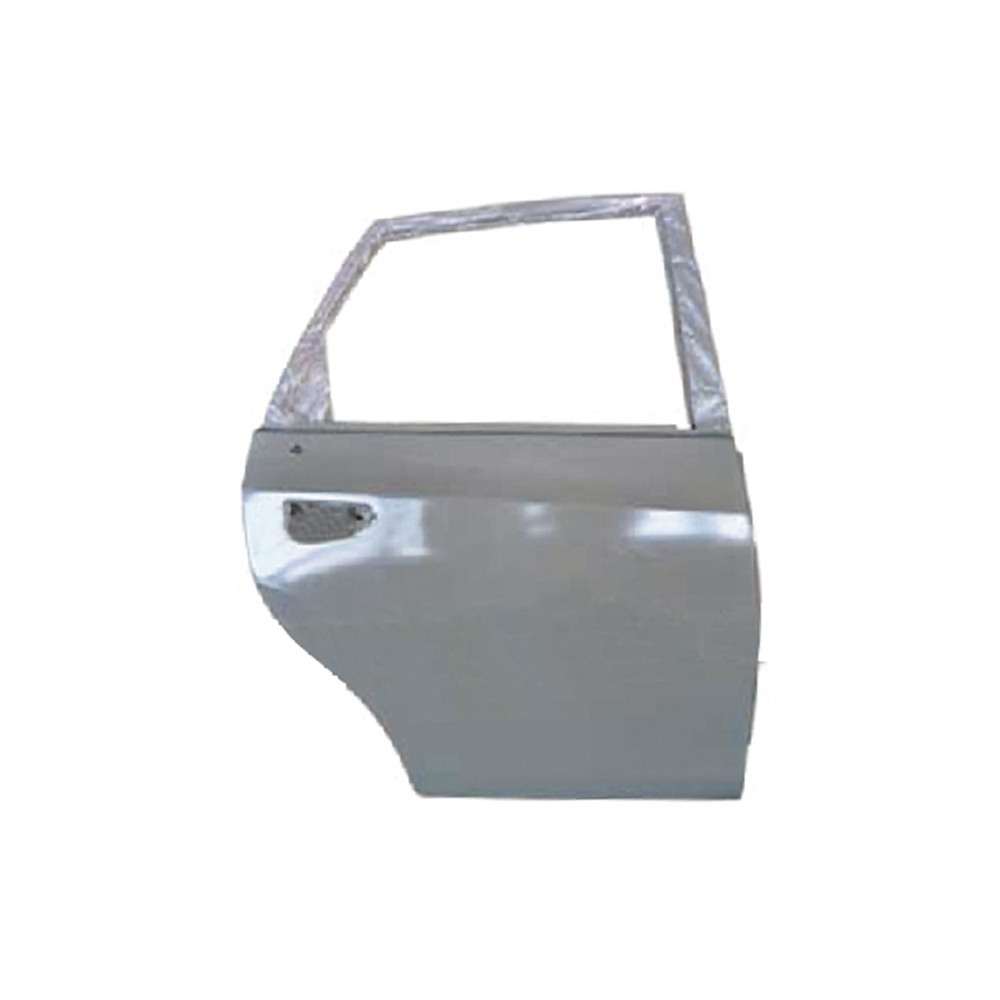

Metal replacement parts play a crucial role in maintaining vehicle integrity after collisions or during periodic overhauls. When a fender, hood, or door panel needs replacement, precision and compatibility are key factors that determine the quality of the repair. Jac Parts are produced using advanced forming and stamping techniques that ensure accurate dimensional matching with the original structure of the vehicle. This precision simplifies the installation process and guarantees that the restored vehicle maintains its original aerodynamic design and body alignment.

Durability is another defining feature of Jac Parts. Manufactured using high-quality alloys and corrosion-resistant coatings, they can withstand exposure to moisture, debris, and changing temperatures. This is especially important for vehicles that operate in diverse environments, from urban delivery fleets to long-haul commercial trucks. The metal surface treatment not only prevents rust and oxidation but also ensures the panels maintain their appearance and functionality for years of use.

Equally important is the ability of these components to absorb and distribute impact energy. In the event of a collision, the structural design of Jac Parts contributes to the safety of passengers by helping the vehicle body maintain its energy absorption characteristics. Through optimized thickness distribution and material selection, these parts meet rigorous safety standards while providing long-term reliability. Whether used for light maintenance or full structural reconstruction, they support the mechanical and aesthetic integrity of every vehicle they are installed on.

How Do Jac Parts Reflect the Precision and Performance Demands of the Automotive Industry?

The manufacturing of Jac Parts represents a combination of precision engineering and industrial innovation. Each piece, from a compact hood to a heavy-duty fender, undergoes a series of quality-controlled processes that ensure performance under various driving and loading conditions. This approach allows every part to deliver consistent results whether used on a private sedan or a high-capacity light truck.

One of the central aspects of Jac Parts is the emphasis on dimensional accuracy. The components are manufactured through high-tonnage stamping and trimming operations that ensure each surface, curve, and mounting point aligns perfectly with the vehicle’s body framework. This degree of precision eliminates unnecessary fitting adjustments during installation and ensures that the repaired vehicle retains its original aerodynamics, sealing capability, and visual symmetry.

Material performance also plays a decisive role. The metal alloys selected for Jac Parts are optimized for strength-to-weight ratio, allowing for lighter yet stronger panels. The improved tensile and yield strength of these materials not only increases impact resistance but also enhances overall rigidity. This means that even in high-load conditions, such as those encountered by commercial vehicles, the panels maintain stability without deformation.

Furthermore, every Jac Part undergoes corrosion resistance and fatigue testing to ensure endurance in real-world conditions. These tests simulate prolonged exposure to humidity, temperature changes, and road contaminants to evaluate how each component performs over time. The result is a product line that meets or exceeds OEM-level expectations in terms of longevity, safety, and aesthetic restoration.

Surface finishing is another area where attention to detail becomes visible. Advanced coating systems are applied to provide protection and paint adhesion quality similar to original vehicle standards. This ensures that body repairs not only restore structural performance but also deliver seamless visual integration after painting and assembly. The outcome is a professional-grade repair solution that supports both repair technicians and vehicle owners who value reliability and long-lasting results.

What Makes Jac Parts an Efficient and Economical Choice for Vehicle Maintenance and Fleet Service?

In today’s global automotive repair and maintenance market, efficiency and cost-effectiveness are vital. Jac Parts are designed to meet these requirements by providing solutions that simplify repair workflows, reduce downtime, and extend vehicle service life. Whether for private car owners or commercial fleet operators, their value lies in combining high manufacturing quality with practical performance.

Ease of installation is one of the major advantages of Jac Parts. Since each component is designed to match the dimensions of the original vehicle, technicians can perform replacements quickly without the need for complex modifications. The precision-fit structure also minimizes the risk of installation errors, helping reduce labor time and ensuring that repairs maintain the same performance characteristics as the original build. This reliability translates directly into faster turnaround times and reduced operational costs for workshops and fleet maintenance centers.

The adaptability of Jac Parts further enhances their appeal. They are suitable for a wide range of repair scenarios, including minor collision recovery, body panel refurbishment, and full exterior restoration. For commercial vehicles, where downtime can result in significant financial losses, having access to reliable replacement panels that fit accurately and perform consistently is essential. Their versatility across multiple vehicle categories makes them an ideal choice for large-scale service networks and independent repair shops alike.

From a cost-performance perspective, Jac Parts achieve an effective balance between affordability and quality. By utilizing advanced production technologies and efficient material utilization strategies, the parts maintain a high level of durability and consistency without excessive production costs. This approach enables repair professionals and end-users to access OEM-level performance at a competitive price point.

The precision of structural alignment in Jac Parts also supports consistent long-term maintenance. Every mounting point, edge contour, and panel curvature is designed to integrate seamlessly with the existing body frame, maintaining aerodynamic performance and structural integrity. Once installed, the repaired section performs identically to the original body design, ensuring stability and comfort during driving. Consistent geometry reduces vibration, wind noise, and stress on adjoining components, extending the service life of both the replaced part and the entire vehicle structure.

Durability under demanding road and weather conditions is another aspect that defines Jac Parts. Each component undergoes extensive testing to confirm resistance to impact, deformation, and corrosion. Vehicles equipped with these parts maintain stable appearance and mechanical strength even after prolonged exposure to moisture, dust, and temperature fluctuations. The robust coating system used during production prevents oxidation and rust, preserving surface smoothness and paint adhesion for years. These characteristics make them a dependable choice for regions where vehicles face frequent environmental challenges.

The long-term benefits of using Jac Parts extend beyond immediate repair. The superior corrosion protection, impact strength, and dimensional stability contribute to the overall vehicle lifecycle, reducing the frequency of replacements and maintenance interventions. This reliability enhances vehicle resale value and ensures that owners can maintain both safety and aesthetics with minimal additional investment.

Jac Parts represent a comprehensive solution for modern automotive body repair, balancing strength, precision, and efficiency. Their design philosophy is rooted in meeting the demanding standards of the metal sheet replacement parts industry, where every detail, from alloy selection to surface finishing, plays a vital role in achieving optimal performance. As vehicles continue to evolve in structure and design, the need for high-quality, precision-engineered metal panels will only grow. Jac Parts stand as a practical, cost-effective, and technically advanced choice that ensures every repair maintains the original performance, safety, and appearance of the vehicle.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体