Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

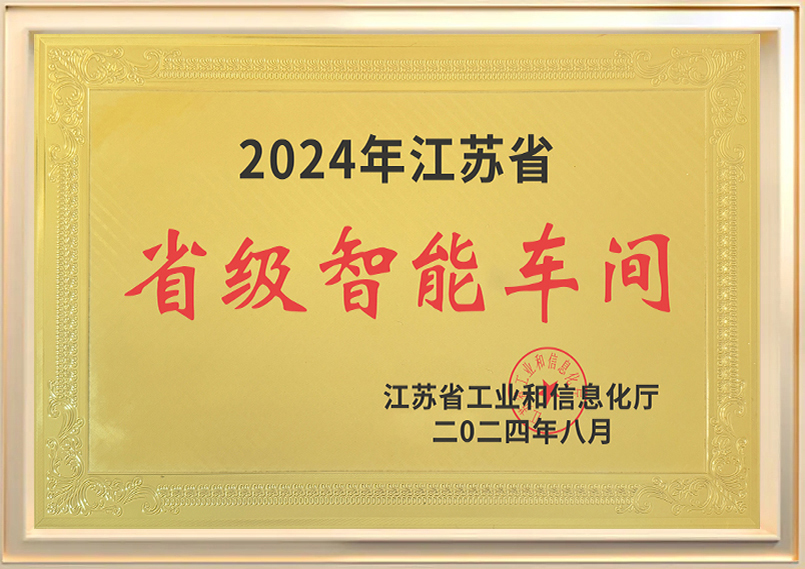

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Geely Parts Manufacturers and Custom Geely Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

News Center

Pay Attention To Our Latest News And Exhibitions

Geely Parts Industry knowledge

The core of our advanced manufacturing capabilities lies in the use of cutting-edge technologies. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we understand that modern automotive components require the highest levels of precision and innovation. To meet this demand, we have integrated state-of-the-art machinery, automated systems, and smart technologies into our production lines. Our facilities are equipped with advanced CNC (Computer Numerical Control) machines, which enable us to manufacture high-precision parts with tight tolerances. These machines allow us to produce complex automotive components that are crucial for vehicle performance, safety, and reliability. The use of CNC technology minimizes human error and ensures that each part we produce is consistent in terms of quality and fitment. We employ robotic automation across various stages of production. Automated robotic arms handle tasks such as material handling, assembly, welding, and part inspection. This reduces the need for manual intervention, increases efficiency, and improves consistency throughout the manufacturing process. The integration of robotics not only enhances the speed of production but also ensures that our parts meet the rigorous safety and quality standards required by the automotive industry. Jiangsu Juncheng Vehicle Industry Co., Ltd. has incorporated additive manufacturing technologies, also known as 3D printing, to expedite product prototyping and low-volume production. This capability allows us to produce prototypes quickly, iterate on design concepts, and make adjustments before mass production begins. Additive manufacturing also supports the development of customized parts, enabling us to offer tailored solutions to our clients.

Automation and robotics play an integral role in improving both the efficiency and consistency of our production processes at Jiangsu Juncheng Vehicle Industry Co., Ltd.. By implementing automated systems and robotic solutions, we have created a highly efficient manufacturing environment that minimizes human error, reduces production time, and enhances output consistency. Our automation systems are designed to handle repetitive tasks such as assembly, welding, and painting with high precision, ensuring that every part we produce is uniform and meets the highest quality standards. Robotics in our manufacturing processes are not limited to simple tasks; they are equipped with advanced sensors and cameras to perform complex quality control checks. Robotic arms, for example, are able to carry out precise welds on metal components, inspect the integrity of the welds, and even carry out paint coatings with uniform thickness. These robotic systems are programmed to detect potential issues in real-time and alert operators to make adjustments before any defects can affect the overall quality of the part. This level of automation ensures that we consistently produce automotive components that are defect-free and fit for use in high-performance vehicles. In addition to improving quality, robotics significantly enhance production speed. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we operate automated assembly lines that are capable of running 24/7, with minimal downtime for maintenance or adjustments. This constant production capability allows us to meet the large-scale demands of the automotive industry, while still maintaining the high levels of precision and quality that our clients expect. Automation has allowed us to implement more flexible production processes. If demand for a particular Geely Auto Part increases, we can quickly adjust our robotic systems to ramp up production without compromising quality or efficiency. The combination of robotics and automation is integral to our manufacturing philosophy, ensuring that we remain competitive in an increasingly fast-paced automotive industry.

One of the standout features of our manufacturing capabilities at Jiangsu Juncheng Vehicle Industry Co., Ltd. is the flexibility and scalability of our production systems. As the automotive industry is continuously evolving, we recognize that our manufacturing systems must be adaptable to meet changing demands and requirements. We have designed our production facilities with flexibility in mind, allowing us to produce a wide range of Geely Auto Parts, from high-volume standard components to highly specialized parts for niche applications. Our production lines are modular and can be easily reconfigured to accommodate new product designs or changes in production volume. This means that when a client requests a new Geely Auto Part or a modification to an existing part, we can quickly adjust our processes and machinery to begin production without extensive downtime. This flexibility ensures that we are able to support automotive manufacturers through all stages of production, whether it's the introduction of a new model or the ongoing production of an established vehicle line. The scalability of our manufacturing systems is equally important. As the demand for certain Geely Auto Parts fluctuates, we can scale our operations up or down in response. Whether our clients need a few thousand components for a limited production run or millions of parts for mass production, our systems can handle the volume without compromising on quality. The combination of flexible and scalable systems allows us to provide optimal solutions for both large multinational automotive companies and smaller, specialized manufacturers. Jiangsu Juncheng Vehicle Industry Co., Ltd. leverages advanced scheduling and resource management software to optimize production planning and inventory control. By using real-time data and analytics, we can ensure that materials are available when needed and that production schedules are met efficiently. This reduces waste, minimizes lead times, and enables us to respond quickly to market demands.

At Jiangsu Juncheng Vehicle Industry Co., Ltd., we implement lean manufacturing practices throughout our production process to maximize efficiency and minimize waste. Lean manufacturing is a methodology focused on eliminating inefficiencies and optimizing every step of the manufacturing process. We continuously analyze our workflows to identify and remove wasteful practices, ensuring that our operations are as streamlined and cost-effective as possible. One key aspect of our lean approach is the reduction of inventory levels. We use just-in-time (JIT) inventory systems, which allow us to maintain minimal stock while still ensuring that we have the materials needed to meet production schedules. This approach helps to reduce storage costs and eliminates the risk of material obsolescence. JIT systems enable us to respond quickly to changes in demand, ensuring that we are never overstocked or understocked. We also focus on improving the flow of materials through our production facility. By reorganizing our production lines and optimizing material handling processes, we reduce the time required to move materials from one workstation to the next. This improves the overall efficiency of our operations, reduces cycle times, and ensures that our workers spend more time focusing on value-added tasks rather than waiting for materials or dealing with bottlenecks. Jiangsu Juncheng Vehicle Industry Co., Ltd. fosters a culture of continuous improvement. Our teams regularly engage in Kaizen events, where employees at all levels are encouraged to identify areas for improvement and suggest changes. These incremental improvements help us achieve long-term gains in efficiency, quality, and customer satisfaction. By fostering a mindset of constant enhancement, we ensure that our manufacturing processes remain agile and adaptable to future challenges.

Quality control is an integral part of our manufacturing process at Jiangsu Juncheng Vehicle Industry Co., Ltd.. Precision is not just a goal; it is a standard that we maintain across all our operations. Our rigorous quality control system ensures that each Geely Auto Part we produce meets the highest standards of performance, safety, and durability. Our quality control process begins with the selection of raw materials. We carefully vet our suppliers and ensure that the materials we use are of the highest quality, adhering to both international and industry-specific standards. Upon receiving materials, we perform thorough inspections to confirm that they meet our strict requirements before they are introduced into the production process. During production, we employ advanced measurement and inspection tools to monitor the dimensions and tolerances of each part. Coordinate Measuring Machines (CMMs) and laser scanners are used to verify that the parts are produced to exact specifications. We also use non-destructive testing methods to detect any hidden flaws in metal components, ensuring that every part meets our durability and performance standards. In addition to these inspection processes, Jiangsu Juncheng Vehicle Industry Co., Ltd. performs functional and stress tests on critical components. For example, parts subjected to high levels of heat, pressure, or wear during vehicle operation are rigorously tested to ensure they will perform optimally throughout the lifespan of the vehicle. We also conduct tests to assess the longevity and reliability of parts under simulated real-world conditions. Only after passing these stringent quality checks do we approve the parts for shipment. This thorough and consistent approach to quality control ensures that our customers receive parts that are reliable, durable, and built to perform under the most demanding conditions.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体