Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

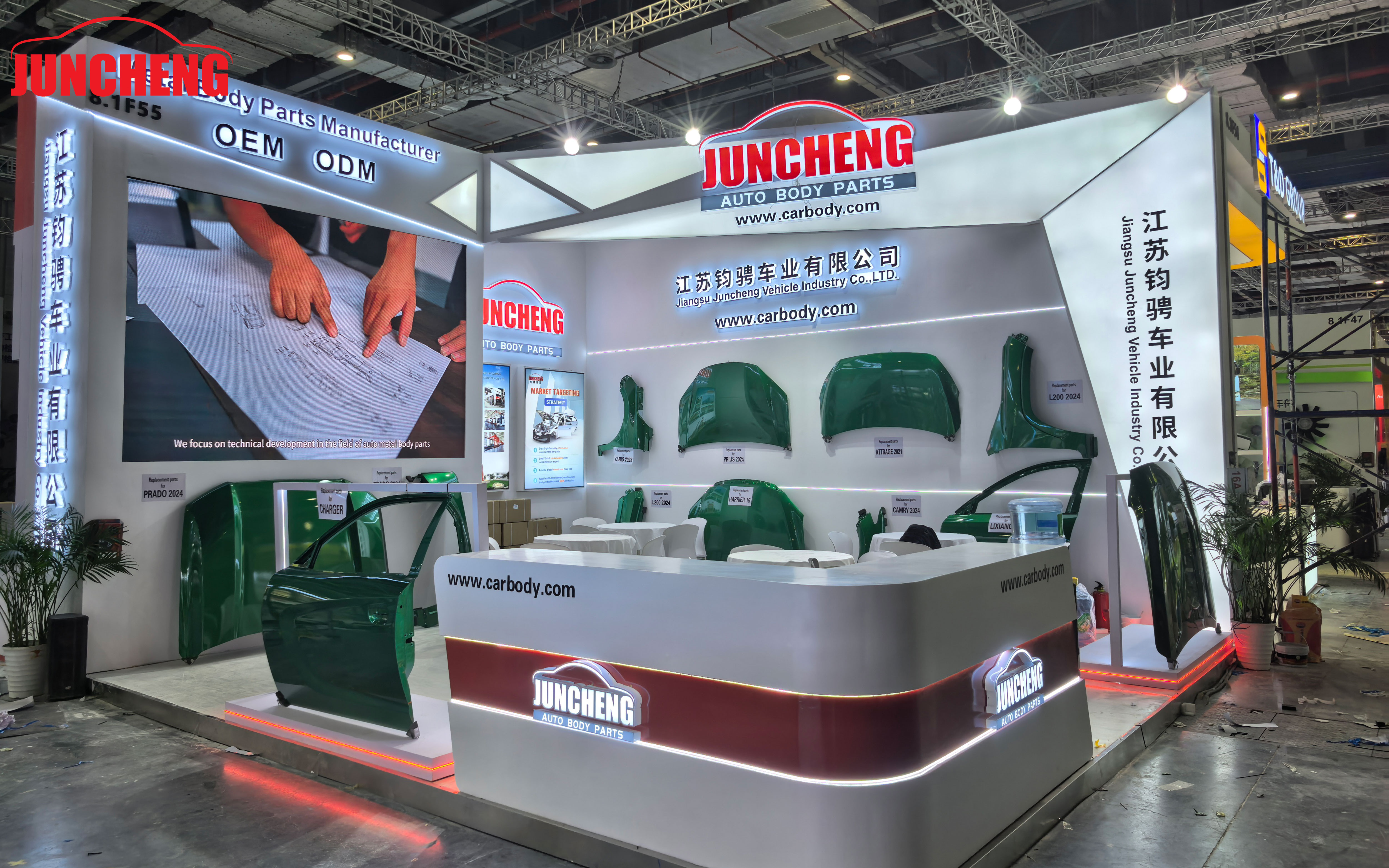

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Opel Parts Manufacturers and Custom Opel Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

Our Certificates

News Center

Pay Attention To Our Latest News And Exhibitions

Opel Parts Industry knowledge

The foundation of any quality automotive part begins with the raw materials. We understand that every component's reliability and performance depend on the quality of the material used to manufacture it. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we take significant care in sourcing only the highest quality metals, such as steel, aluminum, and alloys, ensuring that every part is built on a solid base. The material selection process begins with comprehensive market research and the establishment of long-term relationships with trusted suppliers, ensuring that every batch of material meets international standards for automotive applications. Before we proceed to manufacturing, we carry out stringent inspections of the incoming raw materials. Each material batch is subjected to: Visual Inspections: To ensure there are no visible defects such as cracks, rust, or improper finishes. This is the first step in eliminating potentially faulty materials. Physical Testing: This includes tensile strength tests, hardness testing, and elongation tests, all of which determine whether the material can withstand the stresses it will encounter during both production and real-world use. Chemical Analysis: We conduct tests to confirm the composition of the material to verify that it meets precise specifications for automotive applications, ensuring it will perform optimally in various conditions. Once these checks are passed, we proceed with manufacturing. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we make sure that only materials that pass our rigorous testing processes are used, ensuring that every component we produce is both reliable and durable.

Design validation is a crucial step in ensuring that every Opel part meets both the functionality and fitment standards required in modern vehicles. Before full-scale production, Jiangsu Juncheng Vehicle Industry Co., Ltd. creates a prototype based on the CAD models and designs we develop. These prototypes are subjected to a series of testing phases to evaluate the real-world performance and functionality of the parts. Through prototyping, we can identify potential issues early on, which helps mitigate the risk of defects in the final product. During the validation process, we focus on several key areas: Fitment Testing: One of the primary objectives is to verify that the part fits perfectly within the vehicle and interfaces correctly with other components. Even small discrepancies can lead to significant issues in the final assembly, which is why we conduct rigorous fitment trials on every part. Functional Testing: Every part undergoes functional tests to verify that it performs as designed, from simple mechanical components like gears to more complex systems like suspension or exhaust parts. These tests ensure that the part can handle the daily demands of the vehicle. Stress and Durability Testing: Prototype parts are subjected to extreme stress conditions to evaluate how well they endure factors such as heavy loads, vibration, and high temperatures. This helps to verify that the part will maintain its integrity throughout its lifecycle in the vehicle. Prototyping allows us to catch potential design flaws early and make necessary adjustments, which is an integral part of ensuring that the final production model meets or exceeds all performance requirements. By focusing on early-stage design validation, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures that only parts that have passed rigorous real-world tests enter mass production.

During the production phase, quality control becomes a continuous, integral part of the manufacturing process. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we employ real-time in-process quality checks to monitor the production of every Opel part and ensure it adheres to exacting standards. These checks are performed throughout various stages of manufacturing to ensure any defects are identified and addressed promptly, reducing the risk of production delays or product failure. In-process quality checks typically include: Dimensional Inspections: Utilizing high-precision measuring tools, including micrometers, calipers, and laser measuring systems, we ensure that each part adheres to strict dimensional tolerances. Even slight deviations from the design specifications can compromise the part’s functionality, so these inspections are performed multiple times during the production cycle. Surface Inspections: Parts are thoroughly examined to ensure there are no surface defects such as scratches, blemishes, or deformities that could affect the appearance or functionality of the component. Any imperfections are flagged and corrected before the part moves to the next stage. Assembly Monitoring: For complex parts that require assembly, we ensure that each component is assembled according to strict guidelines, guaranteeing that moving parts function properly and are free from misalignments that could impair performance. By implementing these quality control checks throughout the production process, we prevent minor errors from escalating into major issues. These in-process checks are a cornerstone of our commitment to delivering high-quality Opel parts, allowing us to identify and address defects before they affect the final product.

Final product testing represents the last line of defense before parts are shipped out for distribution. At Jiangsu Juncheng Vehicle Industry Co., Ltd., this stage is one of the most comprehensive parts of our quality control process. By this point, every part should meet the desired specifications, but final inspections ensure that all aspects of the part have been thoroughly evaluated under real-world conditions. We conduct several crucial final inspections: Functional Testing: The final batch of Opel parts is tested under realistic conditions, simulating the physical and environmental stresses the part will encounter in the vehicle. This includes simulating engine operation for engine components, testing suspension parts under load, and ensuring that moving parts perform smoothly under various driving conditions. Dimensional Verification: Even though dimensional inspections were conducted throughout the production process, we perform a final dimensional check to ensure that every part is a perfect match for the design specifications. This includes measuring critical dimensions such as tolerances, angles, and surface profiles. Load and Stress Testing: Many parts, especially structural components like chassis parts or suspension, undergo final load testing. These tests simulate real-world forces and ensure that the parts can withstand the stresses they will experience in actual use without failing or deteriorating prematurely. Safety Inspections: Ensuring that every part meets global safety standards is non-negotiable. We perform thorough safety checks on parts that have a direct impact on vehicle safety, such as brake components, suspension, and airbag systems. Each part is tested for compliance with industry safety regulations and manufacturer specifications. Once the parts have passed final product testing and inspection, only then are they cleared for shipment. This multi-layered approach to final quality control ensures that every Opel part we produce meets the highest standards of safety, performance, and durability.

Even after our Opel parts leave the production line, our commitment to quality control continues. Post-production quality assurance includes actively seeking feedback from customers and conducting further inspections of parts after installation. This step helps us understand the real-world performance of our components and make necessary adjustments for future production runs. We gather feedback through: Customer Reviews and Feedback: We encourage customers to provide feedback on the parts’ performance, especially those involved in high-mileage testing or exposed to extreme conditions. This valuable feedback allows us to assess how well the parts perform over time. Warranty Data and Claims Analysis: Any warranty claims related to our parts are thoroughly analyzed to identify patterns or potential design flaws that may have been missed during production. This data helps us improve our manufacturing processes and update designs when necessary. Performance Monitoring: We monitor the long-term performance of our parts through customer and partner reports, ensuring that any issues are addressed promptly and preventing future occurrences. Post-production inspections, customer feedback, and continuous improvement ensure that we continue to refine and enhance our products, further reinforcing our commitment to quality and performance.

At Jiangsu Juncheng Vehicle Industry Co., Ltd., technology plays a significant role in ensuring the accuracy and efficiency of our quality control processes. Through the integration of advanced technologies, we can monitor, test, and adjust every aspect of production, ensuring that all Opel parts meet the highest standards. Key technologies that aid our quality control include: Automated Optical Inspection (AOI): We use high-resolution cameras and advanced image processing algorithms to inspect the surface of every part at incredibly high speeds. This allows us to detect even the smallest defects that could affect the part's performance or appearance. 3D Scanning and CAD Comparisons: By using 3D scanning technology, we can compare the finished part to its CAD model, ensuring that it has been produced to the exact specifications. This method helps us detect any discrepancies in real-time and correct them before the part moves forward in production. Computer Numerical Control (CNC) Machines: Our CNC machines allow for highly precise machining of parts. These machines operate according to precise programming and ensure that every component is manufactured to exact tolerances, reducing the likelihood of human error and improving overall product quality. Advanced Testing Equipment: We use state-of-the-art equipment to simulate real-world stress, temperature fluctuations, and mechanical wear to verify that every part will perform as intended over its lifetime. Through the integration of these technologies, we not only improve the accuracy of our quality control but also increase the efficiency of the entire production process, ensuring that we deliver consistent and reliable Opel parts every time.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体