1. The Core Role and Importance of Suzuki Parts Factories

Suzuki parts factories play an indispensable role in the global automotive supply chain. As a world-renowned automobile brand, Suzuki relies on high-quality parts to ensure the performance, stability, and safety of its vehicles. For a company like Jiangsu Juncheng Vehicle Industry Co., Ltd. (Juncheng Vehicle Industry), a supplier of automotive parts, collaborating with global manufacturers such as Suzuki underscores its importance in the international automotive industry. Juncheng specializes in providing high-quality sheet metal parts for the automotive manufacturing sector, and has become a long-term supplier for various car brands, including offering essential structural and precision components.

Juncheng Vehicle Industry is not only focused on manufacturing high-quality parts, but also boasts strong research and development (R&D) capabilities. Manufacturing automotive parts requires highly precise processes to ensure the safety and durability of every vehicle. As a company with comprehensive R&D, production, and sales capabilities, Juncheng can customize production according to the specific needs of clients, ensuring that Suzuki and other automotive manufacturers maintain their product quality and production schedules. Juncheng implements a rigorous quality control system throughout the manufacturing process, ensuring that every part meets global automotive industry standards.

The efficiency of parts factories directly impacts the production cycle and delivery capacity of the entire vehicle. With advanced production equipment and technologies, Juncheng ensures that parts are delivered on time to meet the needs of clients. For Suzuki and other automakers, maintaining a stable supply chain is crucial. Juncheng has established a strong global supply chain network, with a branch in the U.S. that specifically handles sales and market development in overseas markets. This enables Juncheng to respond swiftly to market demands and adjust flexibly to global automotive industry changes.

2. Technological Innovations and Automation in Parts Manufacturing

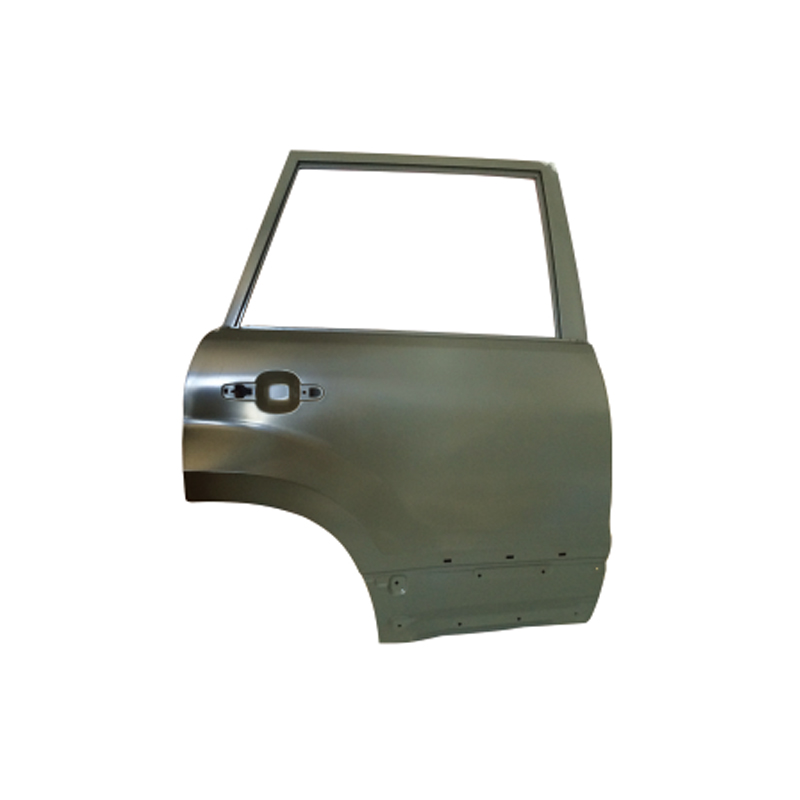

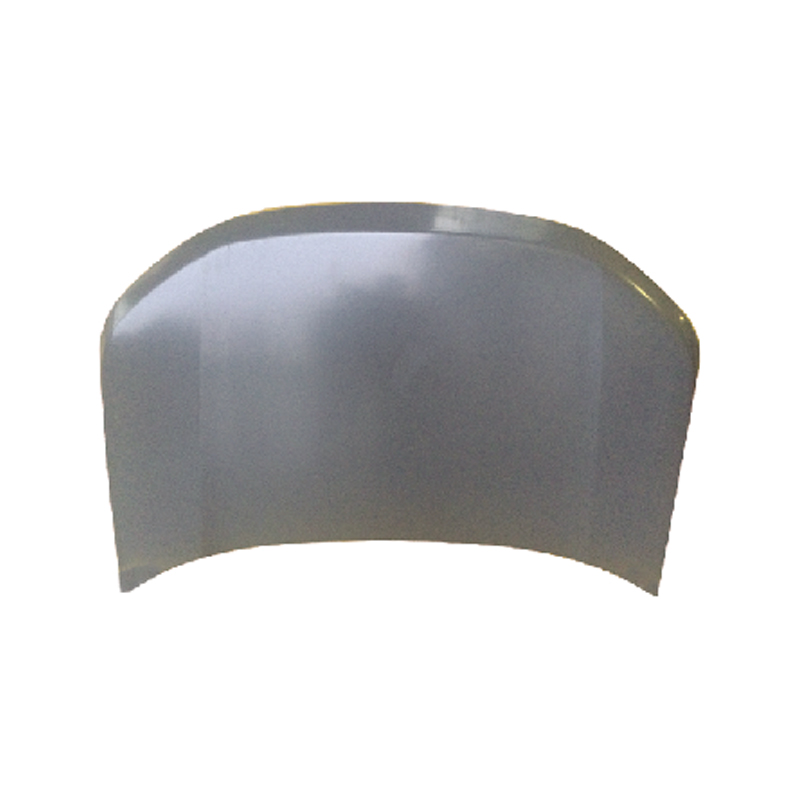

As the global automotive manufacturing industry continues to evolve, technological innovations and the introduction of automation equipment have become key strategies to improve production efficiency and product quality. For Jiangsu Juncheng Vehicle Industry Co., Ltd., the adoption of advanced automation technologies and innovative manufacturing processes has provided a significant competitive edge. Specializing in the research, production, and sales of high-quality automotive sheet metal parts, Juncheng utilizes a wide range of automated production lines, including robotic welding, laser cutting, automated spraying, and 3D printing technologies. These technologies not only improve production efficiency but also ensure higher precision in parts manufacturing, enhancing product reliability and durability.

At Juncheng, precision manufacturing techniques are extensively applied to parts production. For example, laser cutting technology allows for highly accurate cuts in sheet metal, while robotic welding systems ensure the stability and quality of every weld. Automated spraying systems also enhance the surface treatment quality of vehicle body parts, ensuring their corrosion resistance and aesthetic appeal. The application of these technologies not only improves production efficiency but also reduces human error, ensuring consistency and high-quality standards across parts production.

Advanced quality inspection technologies play a crucial role in ensuring the high standards of automotive parts. Juncheng has implemented state-of-the-art visual inspection systems, sensors, and data analytics to provide comprehensive quality control throughout the manufacturing process. By monitoring every step in real time, Juncheng can quickly identify potential issues and make adjustments, ensuring that every batch of parts meets strict quality standards. As smart manufacturing technologies continue to develop, Juncheng is continually optimizing its automated equipment, improving the intelligence of its production lines, which not only saves costs but also offers customers a more stable and high-quality product.

3. Global Supply Chain Challenges and Response Strategies

With the increasing competition in the global automotive industry, automotive parts manufacturers face increasingly complex supply chain challenges. Particularly in the context of rising economic uncertainty, fluctuations in raw material prices, and changes in trade policies, Jiangsu Juncheng Vehicle Industry Co., Ltd. (Juncheng Vehicle Industry) must continually optimize its supply chain management strategies to maintain its competitive edge in the global market. Juncheng is not only a key player in the domestic market but has also expanded its reach to overseas markets through its U.S. branch, which handles sales and market development in the United States. In the face of cross-border supply chain management and market demand uncertainties, Juncheng has implemented several flexible responses.

Juncheng has established a diversified supplier network to reduce its dependence on a single supplier. This strategy allows the company to better manage supply chain disruptions and optimize cost structures through pricing negotiations and procurement strategies. At the same time, Juncheng has increased its local production capabilities to minimize the impact of cross-border transportation and tariffs. By establishing production bases in various regions, Juncheng can more flexibly respond to market fluctuations, ensuring the stability of its supply chain and continuous production.

In addition to supplier management, inventory management is another critical component of Juncheng’s strategy to address supply chain challenges. By introducing information management systems, Juncheng has achieved transparency and real-time monitoring of its supply chain. Using big data analysis, Juncheng can predict demand fluctuations and adjust production plans accordingly, avoiding issues such as stockpiles or shortages. The company strengthens its collaboration with suppliers and partners to ensure a stable supply of raw materials and meet the high-quality standards required for parts production.

Through these strategies, Juncheng has not only ensured the supply of Suzuki parts and other components to major automakers but has also positioned itself strategically in the global automotive market. As market demands continue to evolve, Juncheng will continue to innovate and optimize its supply chain management to address the growing complexities of global competition and provide customers with more efficient, high-quality automotive parts.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体