What types of metal materials are used in the production of Skoda Parts?

In the production of Skoda Parts, especially sheet metal parts (such as body shells, doors, hoods, etc.), Skoda uses a variety of high-performance metal materials to ensure the vehicle's strength, safety, durability, and weight balance. These materials mainly include:

High-Strength Steel (HSS): High-strength steel is a commonly used material in the modern automotive industry, and Skoda also widely uses it in the body structure of its Skoda Parts. It has high tensile strength, which effectively improves the safety of the vehicle body, especially in the event of a collision. The use of high-strength steel makes the body more robust while maintaining a lighter weight, contributing to improved fuel efficiency.

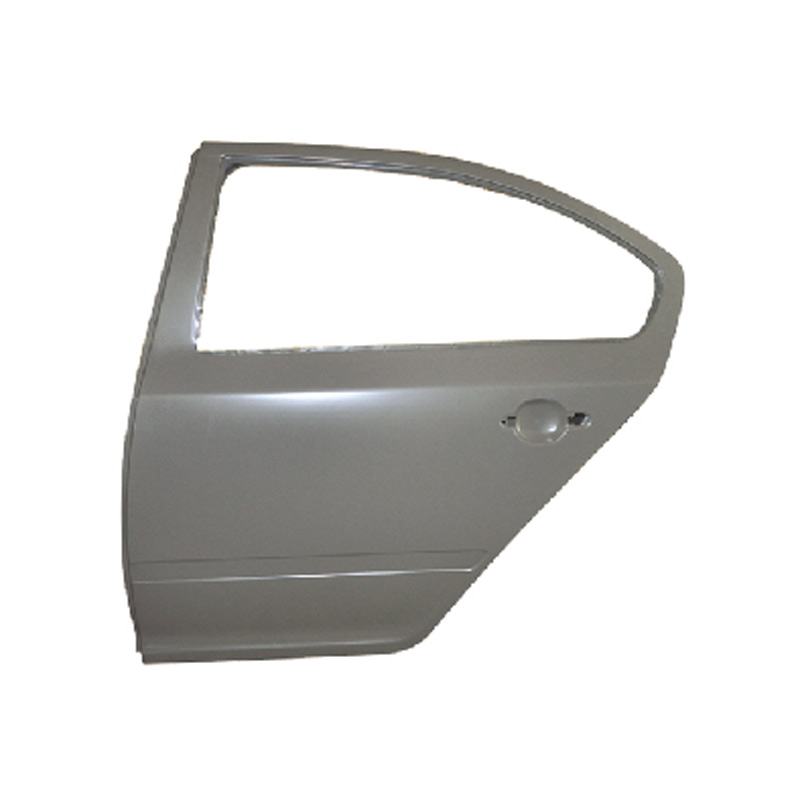

Aluminum Alloys: Aluminum alloys, with their lightweight and good corrosion resistance, are also used in Skoda Parts. Especially in areas where weight reduction is crucial, such as doors, hoods, and chassis, aluminum alloys are used to replace traditional steel, reducing overall vehicle weight and thus improving fuel economy and driving performance.

Galvanized Steel: To improve corrosion resistance, Skoda uses galvanized steel in some Skoda Parts. Galvanized steel has a zinc coating that effectively prevents corrosion from moisture and salt, making it particularly suitable for vehicles operating in humid or salty environments, extending the lifespan of components.

Hot-Stamped Steel: Hot-stamped steel is a material with higher strength after high-temperature processing and is commonly used in critical safety components of Skoda Parts, such as the A-pillars and B-pillars. Through hot forming, these components can provide extremely high impact resistance without adding excessive weight.

Stainless Steel: Stainless steel is also used in some Skoda Parts (such as exhaust systems and exterior trim pieces). It possesses excellent corrosion resistance and high-temperature resistance, making it particularly suitable for components in high-temperature and highly corrosive environments.

By rationally selecting and applying these different types of metal materials, Skoda ensures the performance, durability, and safety of its Skoda Parts, while maintaining a lighter weight without sacrificing strength or stability.

What technologies are used in the anti-corrosion treatment of Skoda Parts?

Anti-corrosion treatment is key to ensuring the long-term durability of Skoda Parts, especially in areas such as body panels and chassis. Skoda employs a variety of advanced anti-corrosion technologies to enhance the corrosion resistance of its metal parts in various environments. Key technologies include:

Hot-Dip Galvanization: Hot-dip galvanizing is a common anti-corrosion technology. Skoda immerses metal parts in a bath of molten zinc, forming a robust zinc protective layer on the surface. This zinc layer not only prevents oxidation but also improves the corrosion resistance of Skoda Parts during long-term use. Especially for exterior body panels, hot-dip galvanizing effectively prevents corrosion from external environmental factors such as rain and salt spray.

Nickel Plating: Skoda employs nickel plating on some Skoda Parts components. This process provides a smooth protective layer to the metal surface, offering excellent oxidation and corrosion resistance. Nickel plating is commonly used on high-end trim pieces or exposed metal parts, such as exhaust systems and body trim strips.

Cathodic Electrophoretic Coating (E-Coating): Cathodic electrophoretic coating is an advanced coating technology commonly used on critical areas such as body panels and chassis. It uses an electric current to evenly deposit coating on the component surface, forming an anti-corrosion layer. This technology effectively increases the corrosion resistance of Skoda Parts, and the uniform coating thickness ensures long-term protection.

Phosphating: Phosphating is a process that forms a phosphate protective layer on the metal surface through a chemical reaction. It is commonly used on Skoda Parts' body panels and chassis components. Phosphating enhances the adhesion between parts and coatings, and improves surface corrosion resistance.

Organic Coatings: Skoda also uses various organic coatings, such as polyurethane coatings, to increase the corrosion resistance and abrasion resistance of parts. This type of coating is typically used for the exterior coating of body parts, effectively preventing the effects of UV radiation, wind and sand erosion, and other factors on the appearance and function of Skoda Parts.

Through these anti-corrosion technologies, Skoda's Skoda Parts maintain good performance and appearance for a longer period in various extreme environments, extending the lifespan of the vehicle.

Are Environmental Measures Taken in the Production of Skoda Parts?

Skoda prioritizes environmental protection and sustainability in the production of Skoda Parts, implementing multiple measures to reduce the environmental impact of the production process and improve the recyclability of parts.

Use of Recyclable Materials: In the production of Skoda Parts, Skoda rigorously selects materials, prioritizing the use of recyclable metals such as aluminum alloys and high-strength steel. This not only meets environmental standards but also helps reduce resource waste. Skoda's partner, Jiangsu Juncheng Vehicle Industry Co., Ltd., employs advanced mold design and manufacturing technologies in its mold factory to improve the utilization rate of metal parts and further reduce waste during the production process. This technology not only improves production efficiency but also maximizes the use of recyclable materials, contributing to an overall reduction in resource waste.

Reducing the Use of Hazardous Substances: Jiangsu Juncheng Vehicle Industry Co., Ltd., as the core factory for mold production, strictly adheres to international environmental standards in mold manufacturing and parts production, ensuring the use of materials and processes that comply with environmental regulations. For example, the company's coatings and metal alloys meet the requirements of being lead-free and free of hazardous chemicals, preventing environmental pollution at the source. Skoda also leverages the technical support of Jiangsu Juncheng Vehicle Industry Co., Ltd. to ensure that Skoda Parts are produced without the use of hazardous substances, reducing air and water pollution.

Energy Efficiency and Waste Management: Jiangsu Juncheng Vehicle Industry Co., Ltd. is committed to improving energy efficiency in its production processes. By optimizing production processes and using advanced automated equipment, it reduces energy consumption and waste generated during production. Simultaneously, the Jiangsu Juncheng Vehicle Industry Co., Ltd. mold factory has a comprehensive waste recycling system that effectively recycles metal scrap, processing residues, and other materials, thereby reducing resource waste and environmental burden.

Skoda collaborates closely with Jiangsu Juncheng Vehicle Industry Co., Ltd., adopting green manufacturing principles and implementing energy-saving and emission-reduction policies to ensure minimal energy consumption and effective control of waste emissions during the production of Skoda Parts. For example, waste materials, cutting oils, and solvents used in automotive parts production are strictly managed to ensure recycling and reuse, minimizing environmental impact.

Environmentally Friendly Coating Technology: Skoda also has high environmental standards for its coating technology. Jiangsu Juncheng Vehicle Industry Co., Ltd. uses environmentally friendly coating processes in mold production, employing water-based coatings and solvent-free coating technologies to reduce emissions of harmful volatile organic compounds (VOCs). This coating technology not only improves the corrosion resistance of Skoda Parts surfaces but also effectively reduces air pollution, contributing to a reduction in greenhouse gas emissions.

Through its collaboration with Jiangsu Juncheng Vehicle Industry Co., Ltd., Skoda ensures that coating materials and processes meet international environmental requirements, further enhancing the environmental performance of parts and ensuring compliance with global environmental standards.

Lifecycle Management and Modular Design: Skoda, in collaboration with Jiangsu Juncheng Vehicle Industry Co., Ltd., has driven the implementation of modular design and lifecycle management, particularly in the production of body panels and other critical components. Through modular design, Skoda optimizes the production and maintenance processes of Skoda Parts, making these parts easier to disassemble and replace, thereby extending the entire vehicle lifecycle and minimizing waste.

During the design process, Skoda pays special attention to the recyclability of Skoda Parts, especially the recyclability of materials. Through appropriate material selection and structural design, it ensures that these parts can be recycled at the end of their lifecycle, reducing environmental impact.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体

.png)

.png)