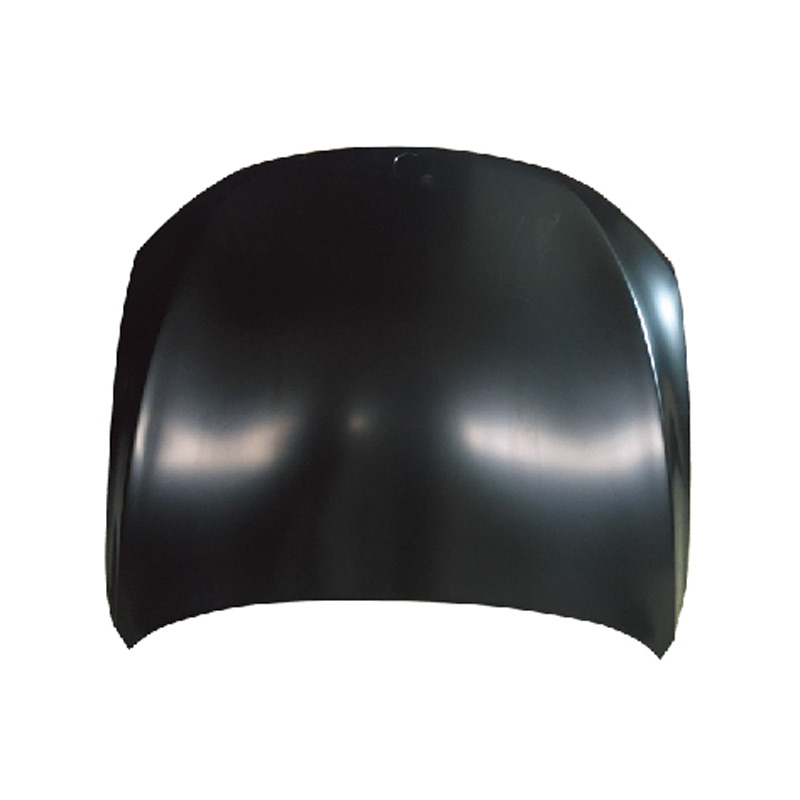

What are the characteristics of material selection for metal sheet metal parts in BMW Parts?

In the production process of BMW Parts, the selection of materials for metal sheet metal parts is crucial, directly affecting the vehicle's safety, durability, performance, and environmental characteristics. When selecting sheet metal materials, BMW primarily considers strength, weight, corrosion resistance, machinability, and environmental friendliness.

High-strength steel: BMW widely uses high-strength steel (HSS) as the main material for metal sheet metal parts, especially in load-bearing structures such as the body and chassis. High-strength steel has high tensile strength and impact resistance, effectively improving vehicle collision safety. In BMW Parts, common high-strength steels also include ultra-high-strength steel (UHSS), which effectively absorbs impact energy during a collision, protecting the safety of occupants.

Aluminum alloys: To achieve lightweighting, BMW widely uses aluminum alloys in many models (especially high-end and electric vehicles). Aluminum alloys not only have a high strength-to-weight ratio but also effectively improve fuel efficiency and dynamic performance. For example, the body and doors of electric or hybrid models like the BMW i3 and BMW i8 are largely made of aluminum alloy. The use of aluminum alloy reduces vehicle weight, contributing to improved battery range.

Magnesium Alloy: BMW also uses magnesium alloy in some lightweight designs. Magnesium alloy has a low density, further reducing vehicle weight, while maintaining good strength, making it suitable for structural components in electric vehicles.

Galvanized Steel: To improve the corrosion resistance of sheet metal parts, BMW uses galvanized steel in many metal sheet metal components. Galvanized steel effectively resists corrosion from moisture, salt, and chemicals in the environment, making it particularly suitable for use in highly corrosive environments such as humid or coastal areas.

Composite Materials: In some high-performance vehicles, BMW has also begun using composite materials (such as carbon fiber reinforced plastic, CFRP) to replace traditional metal materials. These materials not only have extremely high strength but also significantly reduce vehicle weight, increasing dynamic performance and handling. Carbon fiber components in BMW Parts are generally used in high-end models and racing cars, such as the BMW M Series and BMW i Series.

How does BMW Parts control the precision and strength of sheet metal parts during production?

Ensuring the precision and strength of sheet metal parts is crucial in the production process of BMW Parts. BMW employs a series of advanced manufacturing technologies and stringent process control measures to ensure that each component meets its high standards:

Precision Stamping and Die Design: BMW manufactures sheet metal parts using precision stamping processes, utilizing high-precision dies and CNC equipment to ensure that the dimensions and shape of each sheet metal part perfectly match design requirements. Automated stamping and forming processes are used in the production of BMW Parts, significantly improving the precision of sheet metal parts and reducing human error.

Hot Forming Technology: To improve the strength of sheet metal parts, BMW extensively uses hot forming technology in the manufacturing of body structure components. By heating metal to specific temperatures and then forming it, the strength and stiffness of the material can be significantly improved, thereby enhancing crash safety without increasing weight. This technology is particularly important when manufacturing high-strength steel (such as ultra-high-strength steel) components.

Laser Cutting and Welding Technology: While ensuring precision, BMW utilizes laser cutting technology for high-precision cutting of metal sheet parts, reducing material waste and improving dimensional accuracy. Furthermore, BMW employs advanced welding technologies such as laser welding and friction welding to ensure the strength and stability of the joints, reduce welding deformation, and improve weld quality.

Use of High-Strength Materials: For critical structural components, BMW specifically uses high-strength materials such as ultra-high-strength steel (UHSS) and aluminum alloys. These materials not only improve the tensile strength of the sheet metal parts but also increase their impact resistance. This ensures both lightweight construction and vehicle safety and performance.

Quality Control and Inspection: During production, BMW Parts employs a rigorous quality control system. Each metal sheet part undergoes a series of precision tests before leaving the factory, including coordinate measuring machines (CMM) and laser scanning measurements, ensuring that each component meets BMW standards in terms of size, shape, and strength.

What are the anti-corrosion treatments and surface protection technologies used by BMW Parts?

In the production process of BMW Parts, BMW employs a series of advanced anti-corrosion treatments and surface protection technologies to ensure the durability and stability of its sheet metal parts during long-term use. To address corrosion issues in various harsh environments, BMW combines these technologies with high-precision manufacturing processes to ensure excellent performance of components in practical applications. Jiangsu Juncheng Vehicle Industry Co., Ltd., as a supplier, also focuses on surface protection technologies to meet the needs of high-end brands like BMW.

Zinc and Aluminum Plating Treatments: BMW Parts widely uses galvanized steel and aluminized steel in key components such as the body structure and chassis. These treatments effectively improve the corrosion resistance of steel surfaces, especially in humid and saline environments. Through the use of galvanized steel, BMW enhances the durability of sheet metal parts and extends the lifespan of its vehicles.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also uses galvanized materials in its production process and can provide customized surface treatments according to customer requirements. By introducing advanced production equipment, such as the EDP electrophoretic coating production line, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures that the surface of every metal sheet part receives a uniform and strong protective layer, significantly enhancing its corrosion resistance.

Electrophoretic Coating (EDP): BMW employs Electrophoretic Coating (EDP) technology in its BMW Parts production process, particularly in critical areas such as the body and chassis. This technology uses an electric current to evenly coat the metal surface with paint, forming a uniformly thick and strongly adhered protective layer. EDP coatings effectively prevent rust and corrosion on metal surfaces and improve the wear resistance and appearance durability of parts.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also possesses an advanced EDP electrophoretic coating production line, capable of producing over one million sets of body metal parts annually. This coating process is widely used in Jiangsu Juncheng Vehicle Industry Co., Ltd.'s production, providing high-quality corrosion protection for high-end brands such as BMW Parts, ensuring that the surface of metal parts maintains excellent performance during use.

Anodizing Treatment: BMW employs anodizing treatment on lightweight metal materials such as aluminum alloys. This technology forms a thin film on the surface of the aluminum alloy through an electrolytic reaction, giving it excellent corrosion resistance and wear resistance. Anodizing also enhances the surface hardness of aluminum alloys, making them more durable and suitable for high-performance body parts and electric vehicle body materials.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also uses this technology to provide corrosion and wear resistance for body parts when producing aluminum alloy components for BMW Parts. By introducing advanced automated equipment, such as CMM (Coordinate Measuring Machine) and salt spray testing machines, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures precise execution of each surface treatment process, ultimately providing customers with high-quality corrosion-resistant aluminum alloy parts.

Nano Coating and Self-Healing Coating: BMW uses nano coating and self-healing coating technologies in its high-end models. These technologies enhance the surface protection of metal sheet parts. Nano-coatings form an ultra-thin yet robust protective layer on metal surfaces, reducing the adhesion of stains and oil while improving scratch resistance. Self-healing coatings automatically repair minor scratches, extending the lifespan of components.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also focuses on technological innovation and R&D in this area. The company utilizes advanced technologies such as CAE analysis and UG mold design to provide customized surface treatment solutions for its clients. Through these technologies, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures that every metal component it produces possesses excellent corrosion resistance and meets the requirements of leading international automakers.

Corrosion Testing and Quality Control: BMW conducts rigorous corrosion testing on every BMW Parts sheet metal component it produces, including salt spray testing and accelerated aging testing. These tests ensure that its components maintain durability for extended periods in harsh environments, preventing rust and corrosion.

Jiangsu Juncheng Vehicle Industry Co., Ltd. is also equipped with multiple advanced testing devices in its production process, such as salt spray testing machines, tensile testing machines, and defect detection instruments, to ensure that every BMW Parts component meets high-standard quality control requirements. Especially in terms of corrosion resistance, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures that each component meets the high requirements of international customers such as BMW before delivery through rigorous quality testing.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体