What precision manufacturing processes does Volvo Parts use to ensure the structural strength and dimensional accuracy of key components such as the body?

In Volvo Parts' production process, the application of precision manufacturing processes is key to ensuring the superior structural strength and dimensional accuracy of the body and other critical components.

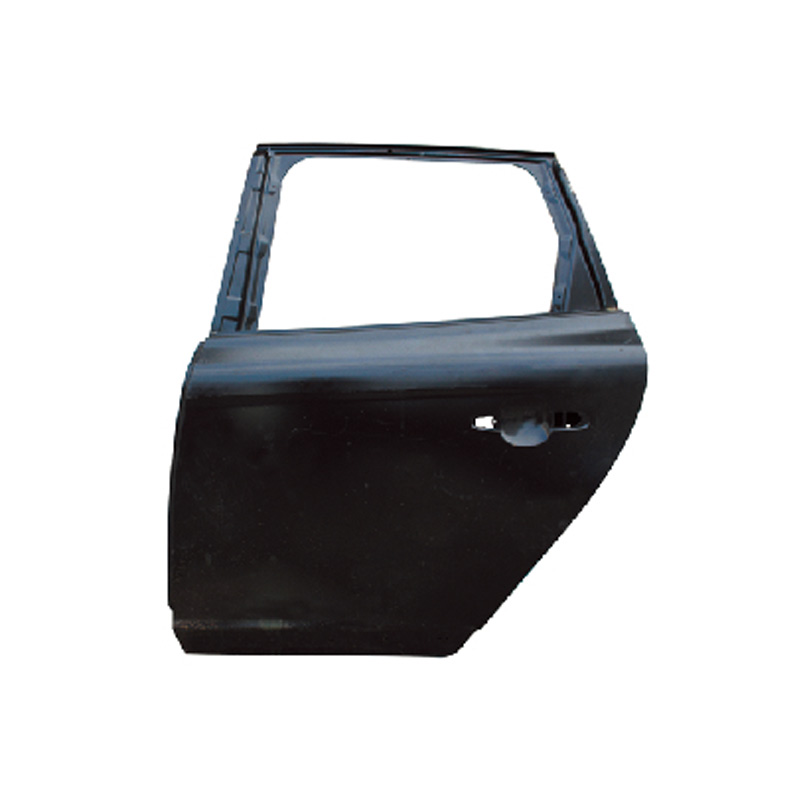

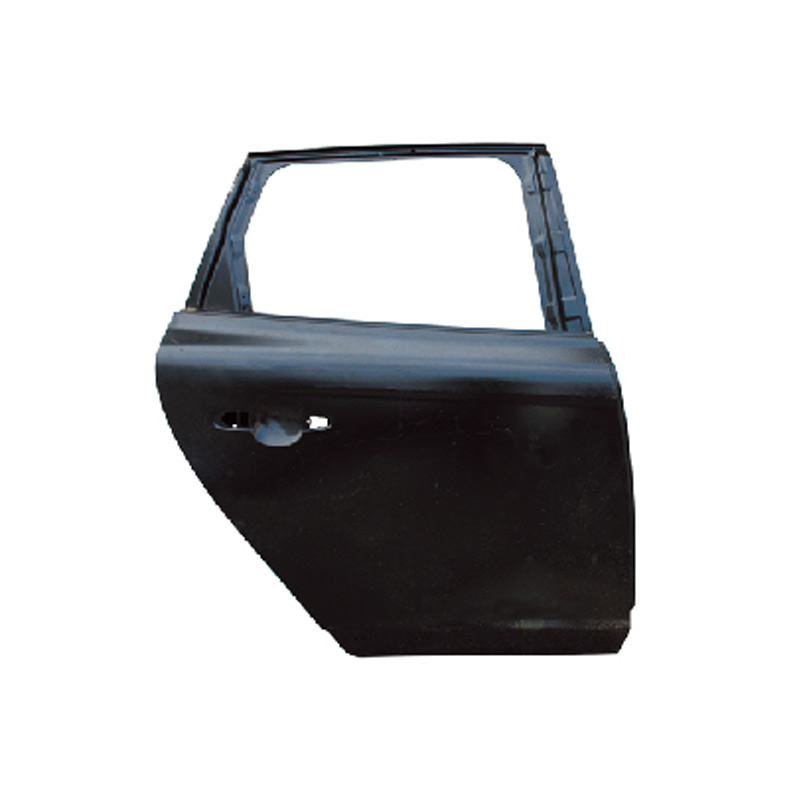

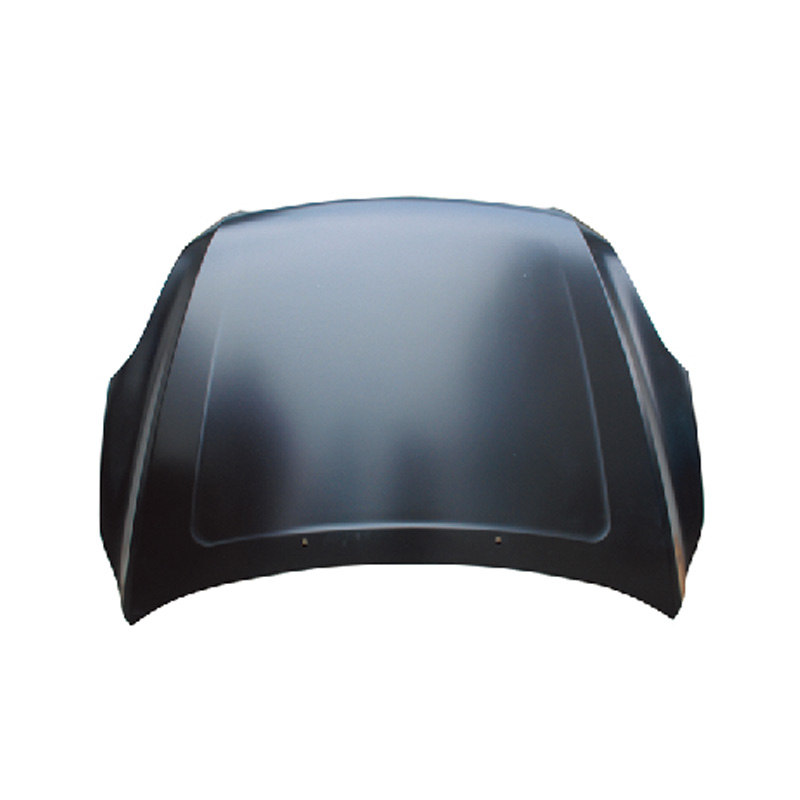

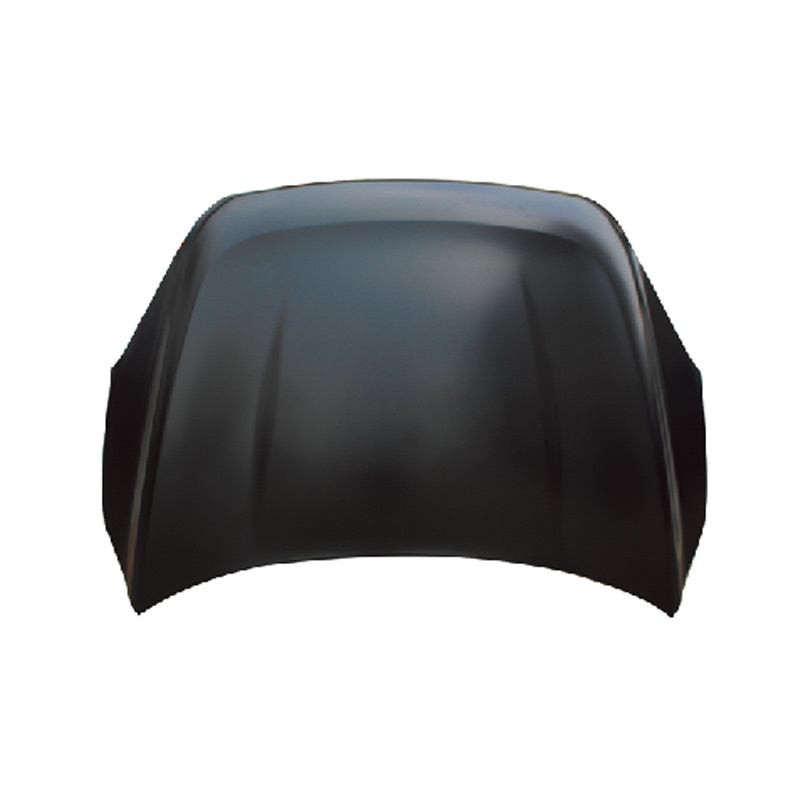

Laser Cutting and Precision Stamping: Volvo Parts extensively uses laser cutting technology in the production of body and structural components. This technology can cut metal sheets with extremely high precision while maintaining the structural integrity of the components. Laser cutting not only ensures the consistency of component dimensions but also reduces the heat-affected zone in traditional cutting processes, thereby maximizing the preservation of the material's mechanical properties. Volvo Parts also employs precision stamping, molding metal under pressure and temperature control to ensure high precision and high strength of various body components (such as doors, sidewalls, and the frame).

Welding and Laser Welding Technology: To ensure the structural strength of Volvo Parts' body components, laser welding technology is widely used in its production process. Compared to traditional welding methods, laser welding offers higher welding precision, less thermal deformation, and greater weld strength, making it particularly suitable for joining thin sheet metals. Through this process, Volvo Parts ensures enhanced safety in the body structure during a collision while maintaining a balance between weight and strength.

Combination of Aluminum Alloy and Ultra-High Strength Steel (UHSS): In its body structure, Volvo Parts employs a combination of aluminum alloy and ultra-high strength steel (UHSS). This combination ensures sufficient strength in a collision while achieving weight reduction. The use of aluminum alloy not only reduces body weight but also improves fuel efficiency and dynamic performance. Ultra-high strength steel provides essential collision safety, especially in critical areas such as doors, A-pillars, and B-pillars, effectively protecting occupants in a collision.

3D Printing and Rapid Prototyping: To further improve the precision and efficiency of the production process, Volvo Parts also utilizes 3D printing technology in the development of some high-precision components. Through rapid prototyping, Volvo Parts is able to perform functional testing and structural optimization of components during the product design phase, ensuring precision and strength in final mass production. This technology significantly shortens product development cycles and improves component consistency.

Does Volvo Parts utilize carbon fiber composites or aluminum alloys in certain high-performance or high-safety models to achieve a balance between lightweighting and strength?

To meet increasingly stringent fuel economy and safety performance requirements, Volvo Parts actively employs carbon fiber composites and aluminum alloys in certain high-performance or high-safety models to achieve a balance between lightweighting and strength.

Carbon Fiber Composites: Carbon fiber composites are widely used in Volvo Parts' high-performance models, particularly in the design of sports sedans and high-end SUVs. The high strength and low weight of carbon fiber make it an ideal material for reducing vehicle weight while ensuring excellent rigidity and crash safety. Especially in non-structural critical components such as the roof, door frames, and dashboard supports, Volvo Parts uses carbon fiber to not only reduce vehicle weight but also improve vehicle handling and acceleration performance.

Wide Application of Aluminum Alloys: Aluminum alloys also play an important role in Volvo Parts' lightweighting strategy. The low density of aluminum alloys makes them one of the preferred materials for lightweight design. Volvo Parts utilizes aluminum alloys in exterior body panels (such as the hood, doors, and tailgate) and some powertrain components (such as the engine hood and chassis) to effectively reduce overall vehicle weight, thereby improving fuel efficiency and reducing CO2 emissions. At the same time, aluminum alloys maintain good corrosion resistance and sufficient strength, ensuring vehicle safety and a long service life.

Combined Use of Aluminum Alloys and Carbon Fiber: For top-of-the-line models, Volvo Parts employs a combination of aluminum alloys and carbon fiber composites. For example, in some high-performance sports cars, Volvo Parts integrates these two materials in the frame, chassis, and body components, ensuring structural strength while significantly reducing weight, optimizing fuel efficiency and handling. This design allows the vehicle to achieve superior performance while maintaining safety.

Does Volvo Parts prioritize renewable materials in parts production to reduce negative environmental impact?

Volvo Parts considers environmental protection measures and the use of sustainable materials in its parts production process. To minimize negative environmental impact, Volvo Parts considers material recyclability not only during product design but also employs many innovative environmental technologies in its production process. Specific measures include:

Prioritizing Renewable Materials: Volvo Parts is committed to selecting recyclable metal materials, such as aluminum alloys and steel, due to their high recycling rates and reuse value. This not only reduces raw material consumption but also allows for effective recycling at the end of the product's lifespan. Furthermore, Volvo Parts also uses bio-based plastics and environmentally friendly fabrics in the interiors of some models. These materials have a lower environmental impact during production and are also highly recyclable.

Application of Green Manufacturing Processes: To reduce energy consumption and waste generation, Volvo Parts uses water-based coatings instead of traditional solvent-based coatings in its production process. This significantly reduces emissions of harmful volatile organic compounds (VOCs). Furthermore, Volvo Parts invests in energy-saving equipment and optimizes production processes to reduce carbon emissions and energy consumption in its factories, ensuring a more environmentally friendly production chain.

Life Cycle Assessment (LCA): Volvo Parts conducts a comprehensive life cycle assessment when designing and manufacturing each component, taking into account the environmental impact of materials, energy consumption during production, and final recycling. Through this approach, Volvo Parts maximizes the sustainability of its components while optimizing the environmental footprint of its products.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also prioritizes environmentally friendly materials and sustainable production. As a company specializing in the research, development, production, and sales of automotive metal sheet parts, Jiangsu Juncheng Vehicle Industry Co., Ltd. employs environmentally friendly materials and recycling measures in its production process. Jiangsu Juncheng Vehicle Industry Co., Ltd. provides its customers with high-quality automotive sheet metal parts, manufactured in strict accordance with environmental standards. These parts typically utilize metals such as steel and aluminum alloys, which not only meet strength and durability requirements but also possess high recycling value, aligning with green production principles.

Through collaboration with various stakeholders in the supply chain, Jiangsu Juncheng Vehicle Industry Co., Ltd. ensures the use of environmentally compliant materials in its production processes and minimizes waste and emissions as much as possible. For example, Jiangsu Juncheng Vehicle Industry Co., Ltd. may employ advanced stamping, welding, and painting processes to ensure part quality while reducing resource consumption and pollutant emissions.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also continuously innovates through technological advancements, developing more environmentally friendly production processes and new materials to further drive the green transformation of the automotive parts industry.

By combining the experience of Jiangsu Juncheng Vehicle Industry Co., Ltd. with the environmental strategies of Volvo Parts, it is evident that as industry requirements for environmental protection increase, automakers are placing greater emphasis on material sustainability and the environmental impact of their production processes. Both companies have taken steps in their respective fields to promote green production and material recycling, reducing their environmental burden.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体