What Material Advantages Make Roewe Parts Essential for Vehicle Longevity?

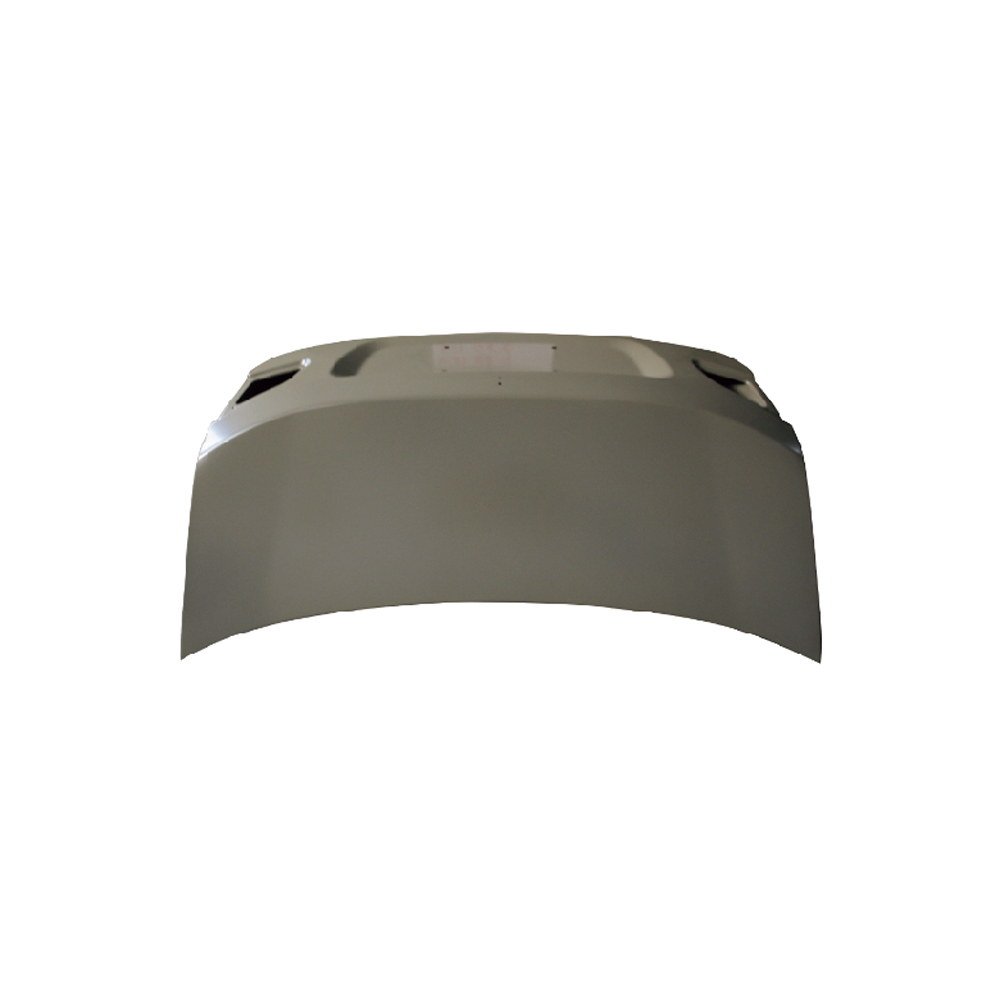

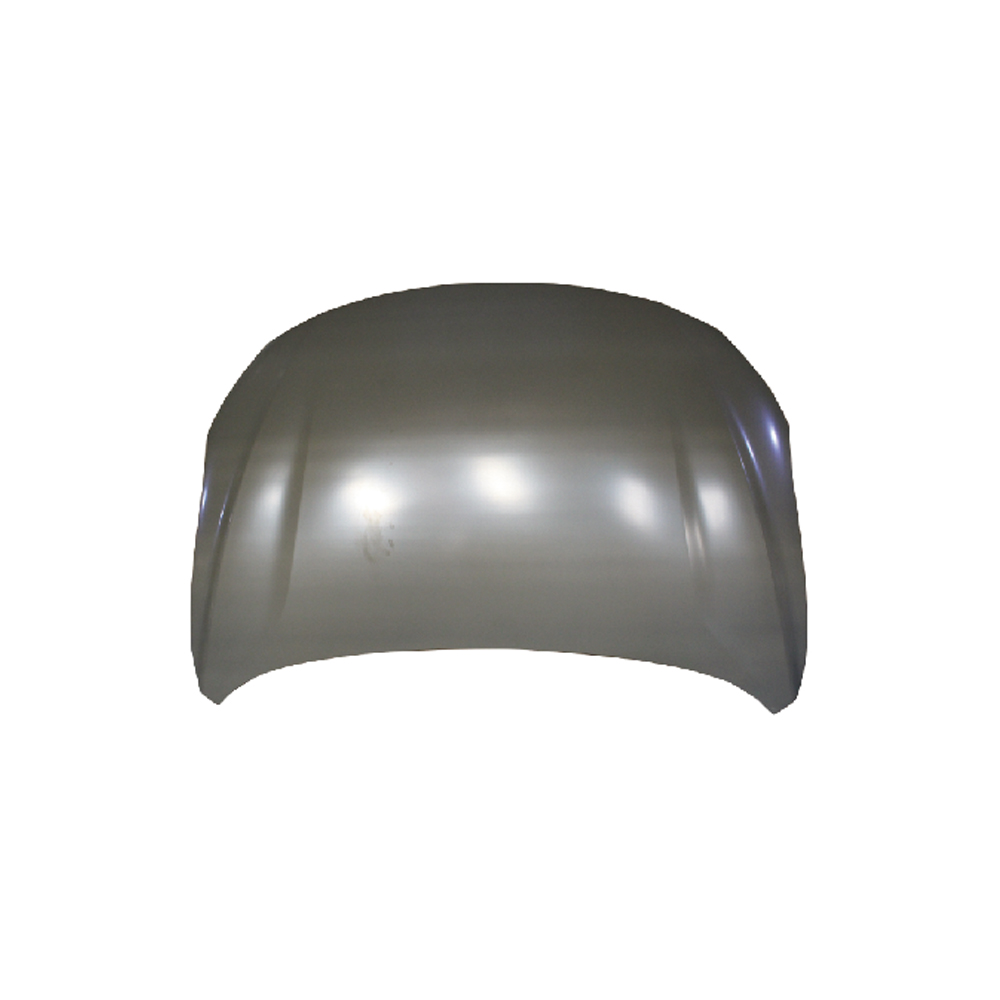

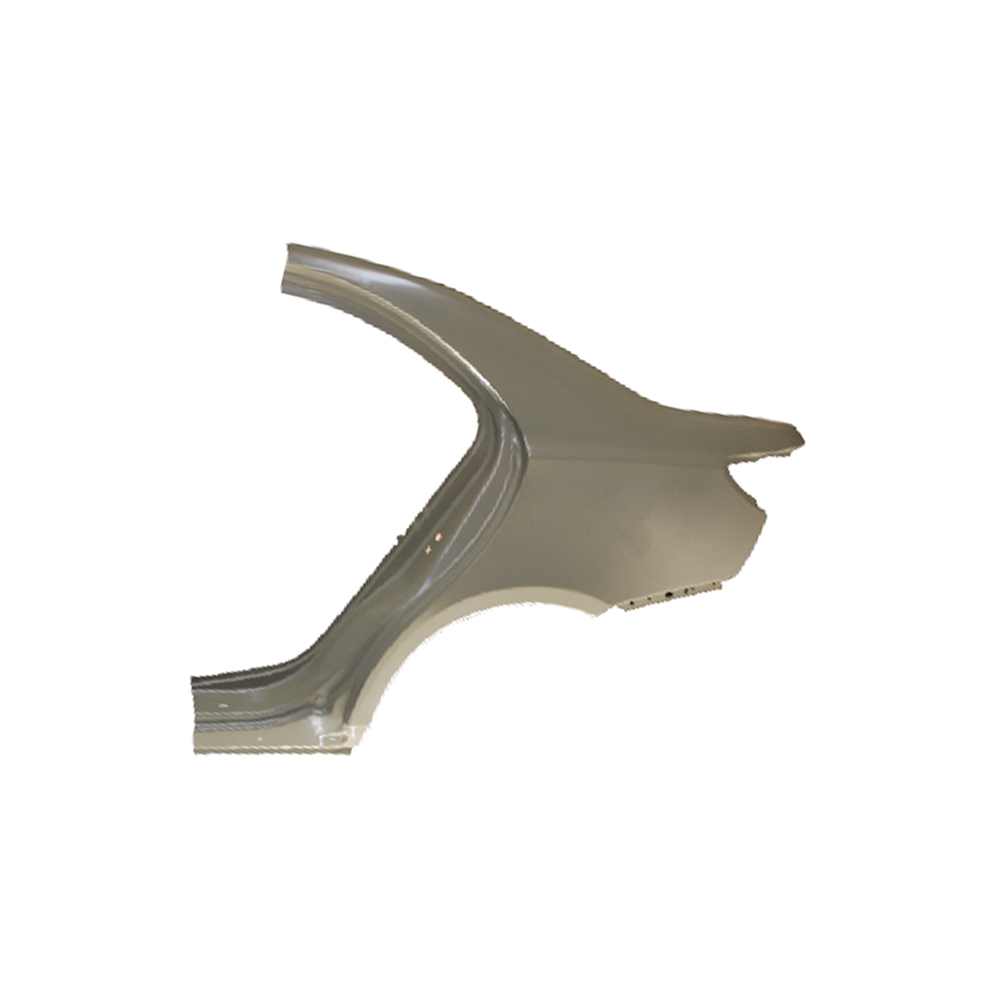

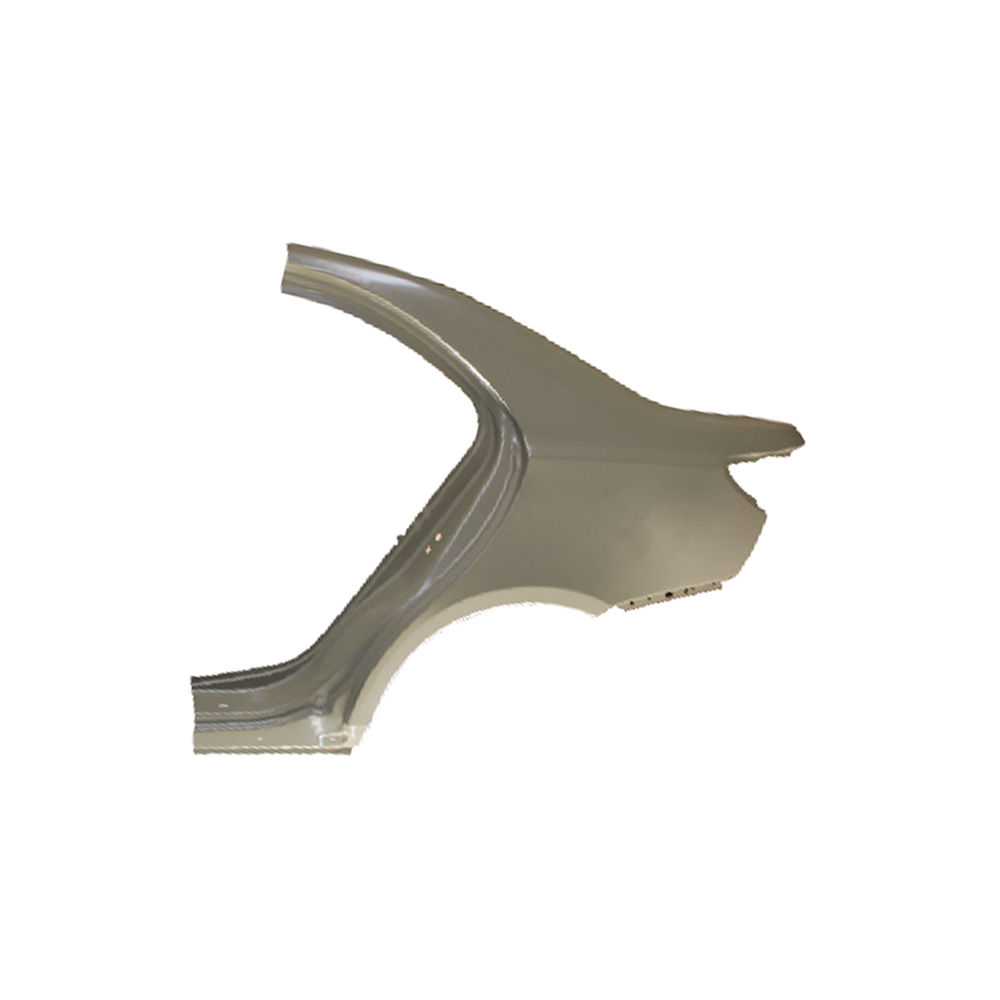

The durability of a vehicle relies on the quality of the materials used in its body structure. Roewe Parts are manufactured from high-strength stamped metals that combine rigidity with controlled flexibility. These panels are engineered to absorb impact energy effectively, minimizing permanent deformation during collisions. High-quality alloys provide resistance to fatigue, ensuring that components retain their structural integrity over time, even under repeated stress.

Material performance also affects repair outcomes. Smooth, uniform sheet metal surfaces allow technicians to achieve precise alignment during installation. Accurate fitment ensures that energy absorption zones and structural supports perform as intended, preserving safety standards. Metal properties such as tensile strength, ductility, and hardness are optimized to balance crashworthiness with everyday handling performance.

The surface treatments applied to Roewe Parts enhance both durability and aesthetics. Anti-corrosion coatings prevent rust and oxidation, while uniform finishes allow for seamless painting and refinishing. Vehicles repaired with these parts maintain visual appeal while benefiting from long-term mechanical protection. By focusing on material performance, Roewe Parts extend the service life of the vehicle and safeguard passenger safety.

Durable materials also reduce the risk of secondary damage during minor impacts. Panels maintain alignment, preventing stress transfer to adjacent components such as door hinges, fender brackets, and suspension attachments. This precision helps preserve the functionality of interconnected systems and contributes to reliable vehicle performance under everyday driving conditions.

The high-strength metals used in Roewe Parts are selected to endure a wide range of environmental conditions. Vehicles face temperature fluctuations, humidity, and exposure to road salts and pollutants, all of which can weaken conventional materials over time. Roewe Parts maintain their mechanical properties under these conditions, ensuring that the vehicle structure remains sound and continues to provide effective protection against external forces. This resilience supports consistent vehicle performance, regardless of climate or driving environment.

In addition to mechanical robustness, these materials contribute to weight efficiency. Carefully engineered sheet metals balance strength with reduced mass, which helps maintain fuel efficiency and handling dynamics. Lighter yet strong panels reduce strain on the vehicle’s frame and suspension system while still providing comprehensive protection. By optimizing both durability and weight, Roewe Parts enhance overall vehicle longevity and create a more reliable platform for long-term use.

How Do Roewe Parts Adapt to Different Models and Environmental Conditions?

Vehicles encounter a wide range of environmental stresses, including humidity, temperature fluctuations, and exposure to urban pollutants or road salts. Roewe Parts are treated with protective coatings that resist corrosion, rust, and environmental wear. This ensures that both structural and aesthetic qualities are preserved over time, reducing the frequency of part replacements and maintenance interventions.

Compatibility with multiple vehicle series is another critical advantage. Roewe Parts cover compact sedans, medium SUVs, and larger MPVs, offering consistent fitment across hoods, doors, fenders, and other structural panels. Standardized design specifications allow a single type of part to serve multiple models, simplifying inventory management for workshops and reducing the likelihood of fitment errors during installation.

Environmental adaptability also enhances long-term reliability. Panels maintain strength and rigidity under extreme weather conditions, including high heat, freezing temperatures, or heavy rainfall. Resistance to corrosion prevents the weakening of joints and structural connections that could compromise safety. Vehicles repaired with Roewe Parts can operate reliably in urban, suburban, or rural environments, ensuring safety and functionality across varied driving scenarios.

Multi-model compatibility supports efficient maintenance workflows. Workshops can stock fewer variations while servicing multiple vehicle types, reducing downtime for customers and optimizing parts logistics. Predictable installation outcomes across different models improve repair efficiency and maintain consistent quality standards.

The engineering of Roewe Parts takes into account differences in vehicle design and structural layouts. Each panel is designed to align precisely with its intended model, maintaining the correct mounting points, angles, and attachment interfaces. This ensures that even when used across multiple models, panels integrate seamlessly with existing frames, preserving handling characteristics, crashworthiness, and overall vehicle balance. Accurate fitment also reduces the risk of vibration, misalignment, or premature wear of adjoining components.

Additionally, Roewe Parts are manufactured to withstand long-term mechanical stress in diverse environments. Road conditions such as potholes, uneven surfaces, or heavy loads can create localized pressure points on body panels. The combination of high-strength metals and protective coatings allows these parts to absorb and distribute stress effectively, preventing deformation and maintaining structural integrity. This adaptability ensures that vehicles remain safe, stable, and functional, whether driving in city traffic or on more demanding routes.

Why Do Roewe Parts Optimize Maintenance Costs and Support Efficient Automotive Repairs?

High-quality sheet metal replacement parts reduce both labor and material costs during vehicle maintenance. Roewe Parts are engineered for precision fit, allowing technicians to install panels without extensive trimming or adjustment. Accurate alignment reduces rework, prevents gaps or misfits, and ensures that body panels integrate seamlessly with existing structures. This leads to faster repair times and lower labor expenses.

Material efficiency is another cost-saving factor. Properly designed panels minimize waste during installation and finishing. Smooth surfaces require less sanding or filler, while uniform thickness ensures consistent painting outcomes. These characteristics reduce the need for repeated interventions, saving both time and resources for workshops and vehicle owners.

The predictable performance of Roewe Parts also supports long-term operational savings. Durable materials, corrosion resistance, and precise engineering reduce the likelihood of premature replacements or post-repair failures. Vehicles maintain their structural integrity, handling, and visual appearance over extended periods, which lowers total cost of ownership.

Efficient automotive repair also benefits from the standardization of Roewe Parts. Replacement panels are compatible with multiple models, allowing workshops to streamline inventory management and training. Technicians can execute repairs with confidence, knowing that panels will fit accurately and perform consistently. This reliability improves workflow, reduces downtime, and increases customer satisfaction.

Using high-quality sheet metal replacements also supports sustainable maintenance practices. Minimal waste, reduced energy use in refinishing, and long-lasting durability contribute to more environmentally responsible repair operations. This combination of cost efficiency, reliability, and sustainability underscores the practical advantages of Roewe Parts in modern automotive maintenance.

The structural integrity provided by Roewe Parts also minimizes indirect repair costs. When panels fit precisely and maintain original vehicle alignment, stress is evenly distributed across the body frame. This reduces wear on connected components such as hinges, suspension mounts, and frame supports, preventing secondary repairs that can arise from misaligned or poorly fitted panels. By preserving the health of adjacent systems, workshops and vehicle owners save both time and money over the long term.

Inventory management is further optimized through the modular design of Roewe Parts. A single type of sheet metal replacement can often serve multiple models or trim variations, allowing repair centers to maintain fewer part numbers while still meeting diverse service requirements. Reduced stock complexity simplifies logistics, lowers storage costs, and enables faster part retrieval during repairs. These operational efficiencies enhance overall service capacity and contribute to a smoother, more predictable repair process.

Roewe Parts combine advanced material performance, environmental adaptability, and multi-model compatibility to provide high-strength, precision-engineered sheet metal replacement parts. These components maintain vehicle safety, structural integrity, and aesthetic quality while supporting efficient and cost-effective automotive repairs. Their durability, corrosion resistance, and predictable fitment ensure long-term reliability across different vehicle models and driving environments. By leveraging superior material properties, adaptability, and efficiency, Roewe Parts offer a practical and professional solution for modern vehicle maintenance, restoration, and long-term service life.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体