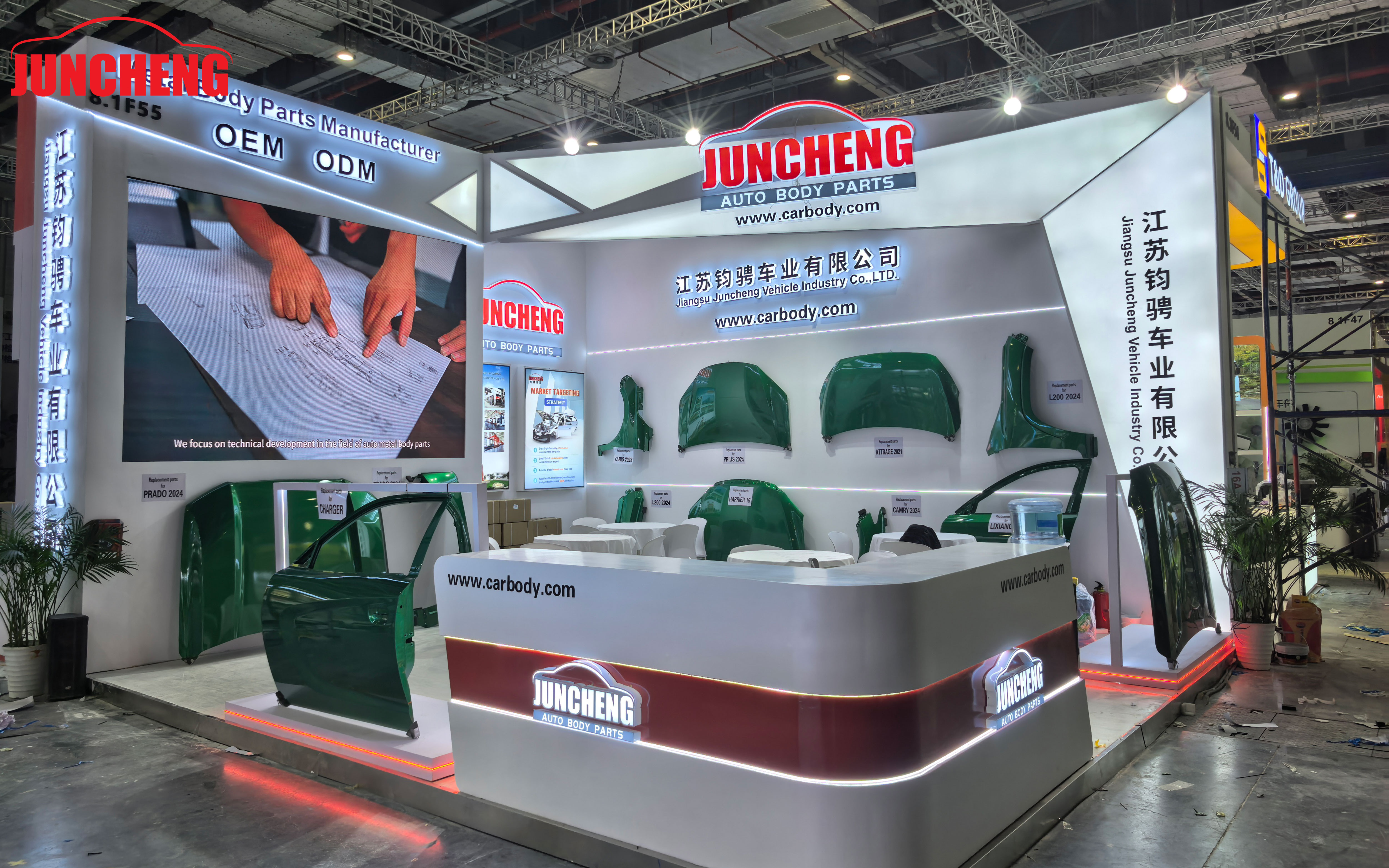

Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Baojun Parts Manufacturers and Custom Baojun Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

Our Certificates

News Center

Pay Attention To Our Latest News And Exhibitions

Baojun Parts Industry knowledge

Precision manufacturing is the foundation of high-quality Baojun parts production. At Jiangsu Juncheng, we leverage advanced precision tools and techniques to craft components with exact specifications. This precision is essential in automotive parts, where even the smallest deviation can impact vehicle performance. Our engineering team employs computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to ensure that every Baojun part, from engine components to suspension parts, is designed and produced to the highest standards of accuracy. By using precision manufacturing techniques, we ensure that each part fits perfectly into the overall system of the vehicle. This is crucial, as a part that doesn’t meet the required dimensions or specifications could lead to inefficiency, safety concerns, or premature failure. Our use of high-precision machinery allows us to manufacture parts with tolerances measured in micrometers, which ensures the long-term durability and optimal functioning of Baojun vehicles. This technology enables us to reproduce parts with great consistency, making sure that the quality of the parts remains the same across all batches. The integration of precision manufacturing also contributes to the reduction of waste and production costs. The advanced machinery used in our facilities allows us to make the most efficient use of materials, reducing excess waste and minimizing the environmental impact of our operations. This approach helps us meet the growing demand for Baojun parts without compromising on quality or efficiency.

In our commitment to producing Baojun parts with exceptional durability and strength, we incorporate advanced casting and forging technologies. These methods are used to create robust and high-performance components that are essential to the structure and functionality of Baojun vehicles. Casting and forging are particularly important when manufacturing parts that must endure high stress, such as engine blocks, suspension components, and transmission parts. Casting involves pouring molten metal into molds to form the desired shape, and at Jiangsu Juncheng, we employ cutting-edge casting techniques that ensure our parts are consistently strong and reliable. We use high-precision molds, which are designed to create parts with excellent dimensional accuracy and surface finish. This is especially critical for parts that are subject to high temperatures, pressure, or mechanical stress. Through advances in casting technology, we can produce complex shapes and designs without compromising the integrity of the material, ensuring the finished Baojun parts meet the rigorous demands of the automotive industry. For parts that require even higher strength and durability, we employ forging techniques. Forging involves shaping metal through the application of heat and pressure, which enhances the material's structural properties. The forging process realigns the metal’s grain structure, improving its toughness and resistance to wear. This is ideal for parts like suspension arms, crankshafts, and other high-load-bearing components, where strength and resistance to fatigue are paramount. By using advanced forging methods, we ensure that these critical components are not only strong but also lightweight and resistant to corrosion. These casting and forging innovations play a critical role in ensuring that Baojun parts are capable of withstanding the stresses and strains of everyday driving, contributing to the overall performance and safety of Baojun vehicles.

The integration of automation and robotics into the production of Baojun parts has revolutionized our manufacturing process, allowing us to enhance efficiency, consistency, and quality control. At Jiangsu Juncheng, we use robotics for repetitive tasks that require precision and speed, such as assembly, material handling, and quality inspections. This reduces human error and ensures that every part produced is identical in terms of specifications, reducing variability and increasing reliability. Robotic systems in our factories are equipped with advanced sensors and vision systems that enable real-time monitoring and feedback. These systems can detect imperfections or deviations from the specified design during production, immediately halting the process if a problem is identified. This capability significantly enhances the overall quality of the Baojun parts we produce, ensuring that no defective components make it to the final stages of production or distribution. Robots are particularly effective in tasks that are labor-intensive and potentially hazardous for human workers. By automating these processes, we not only improve efficiency but also create a safer working environment. The flexibility of robotics also allows us to rapidly adapt our production lines to accommodate different parts, ensuring that our production capabilities can scale to meet the increasing demand for Baojun parts without compromising quality. Automation improves production speed, which is critical in meeting the growing global demand for Baojun parts. This allows us to maintain a competitive edge in the market by delivering high-quality products in a timely manner.

The materials used in the production of Baojun parts play a critical role in their overall performance, strength, and longevity. At Jiangsu Juncheng, we prioritize the use of advanced materials that not only enhance the functionality of our parts but also contribute to the sustainability and fuel efficiency of Baojun vehicles. Through ongoing research and collaboration with suppliers, we ensure that the materials we use are at the cutting edge of automotive manufacturing. Lightweight alloys are one of the key materials we use in the production of Baojun parts. These materials help reduce the overall weight of the vehicle, improving fuel efficiency and lowering emissions. By utilizing materials such as aluminum alloys and magnesium, we can create parts that are both strong and lightweight. For example, aluminum is used extensively in the production of engine blocks, transmission cases, and body components, offering a combination of strength, lightness, and resistance to corrosion. In addition to lightweight alloys, we use advanced polymers and composite materials in parts that require high strength but reduced weight. Composites, such as carbon fiber-reinforced plastics, are particularly beneficial in reducing weight while maintaining superior strength and rigidity. These materials are commonly used in high-performance vehicle components, such as interior parts and structural components that require both durability and low weight. We also place great emphasis on using high-strength steels and alloys for critical components like suspension parts and chassis. These materials are known for their superior resistance to wear and fatigue, which is essential for ensuring the longevity and safety of Baojun vehicles. By continually exploring and adopting the latest advancements in material science, we ensure that every Baojun part meets the high standards expected by our customers.

One of the most exciting technological advancements in Baojun parts production is the integration of digital twin technology. Digital twins create a virtual representation of physical objects or systems by collecting and analyzing real-time data. By implementing digital twins in our manufacturing process, we can simulate, monitor, and optimize the production of Baojun parts from design to completion. The use of digital twins allows us to visualize how each Baojun part will perform under various real-world conditions before it is manufactured. This means we can assess the part’s performance in terms of durability, stress resistance, and thermal efficiency without physically producing the component first. This significantly reduces prototyping costs and accelerates product development cycles, allowing us to bring new Baojun parts to market faster. Digital twin technology enables us to conduct real-time monitoring of the production process. As each part is manufactured, sensors track its performance and condition, sending data back to the digital twin system. If any issues arise during production, we can adjust the process immediately, preventing defects from occurring. This predictive capability ensures that our parts meet the highest standards of quality and performance. The data generated by digital twins can be used for continuous improvement. We use this data to refine our production processes, optimize material usage, and reduce waste. By leveraging this cutting-edge technology, we improve the overall efficiency of Baojun parts production while maintaining rigorous quality control standards.

3D printing has emerged as a transformative technology in the automotive industry, allowing manufacturers to rapidly prototype new parts and designs. At Jiangsu Juncheng, we use 3D printing to accelerate the development of Baojun parts, reducing both the time and cost required to bring new products to market. This technology allows us to create prototypes of parts with complex geometries and intricate details that would be difficult or impossible to achieve through traditional manufacturing methods. The process begins by creating a digital model of the part using CAD software. The 3D printer then constructs the part layer by layer, using materials such as thermoplastics, resins, and metal powders. This approach enables us to quickly test and refine new designs without the need for costly molds or tooling. It also provides us with the flexibility to iterate on designs, making adjustments to the prototype until we achieve the desired performance and fit. In addition to rapid prototyping, 3D printing allows us to produce customized Baojun parts for specific customer needs. Whether for limited-edition models or performance upgrades, 3D printing makes it possible to manufacture low-volume parts with unique specifications. This level of customization is particularly valuable in an industry that demands both mass production and tailored solutions. 3D printing also offers the potential for creating lighter, stronger, and more efficient parts by enabling the use of innovative designs and materials. For instance, by optimizing the internal structure of a part using lattice or honeycomb patterns, we can reduce weight without sacrificing strength. This has a significant impact on improving the overall efficiency and performance of Baojun vehicles.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体