Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

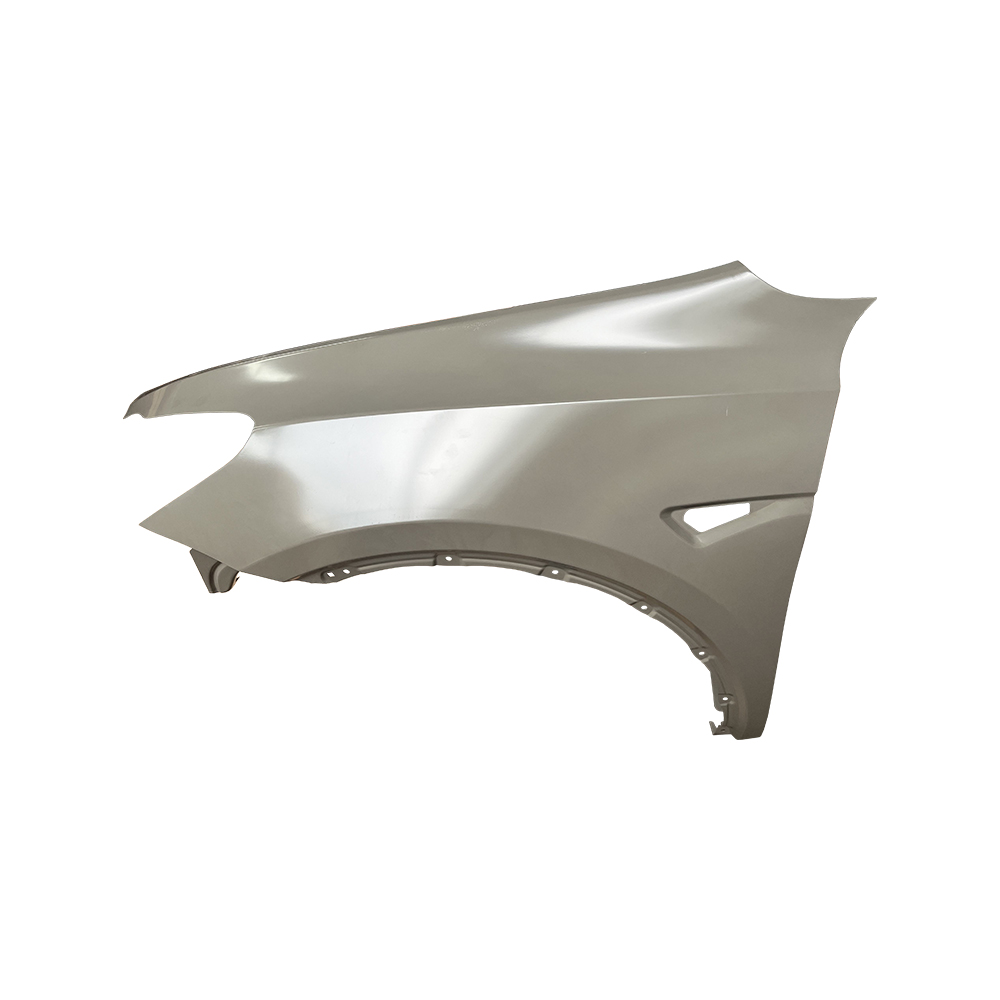

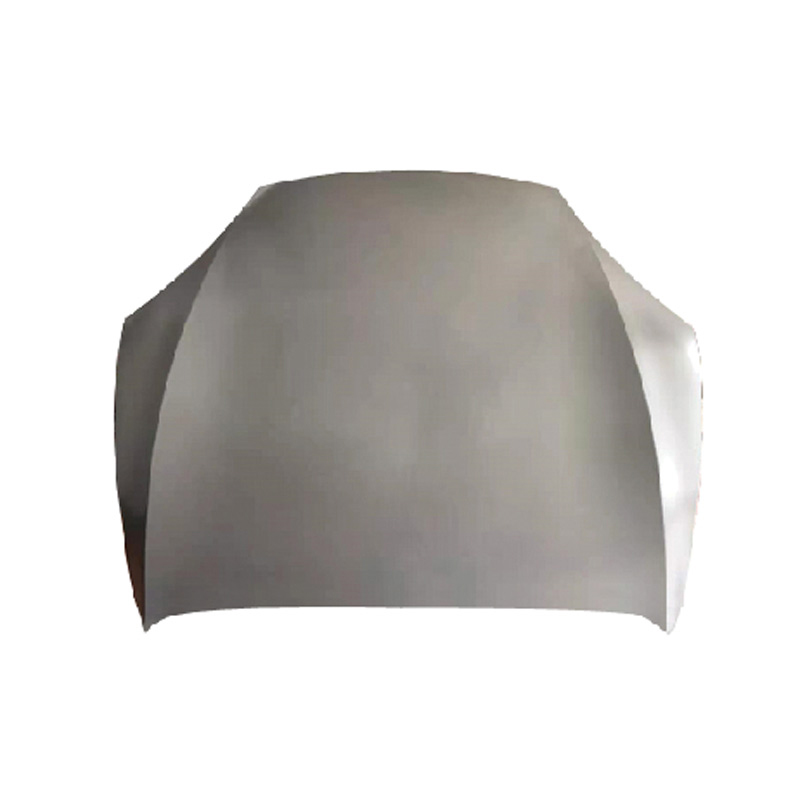

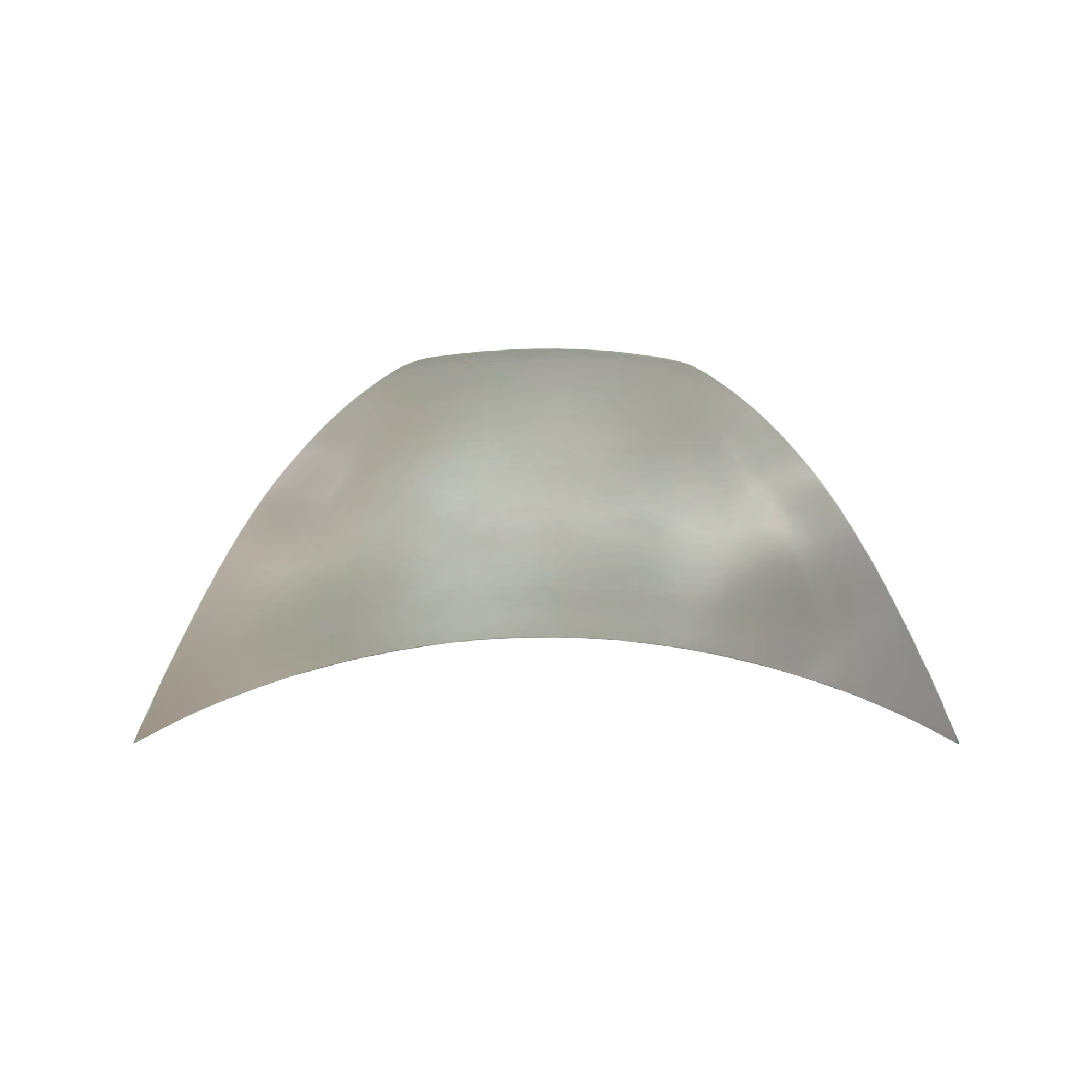

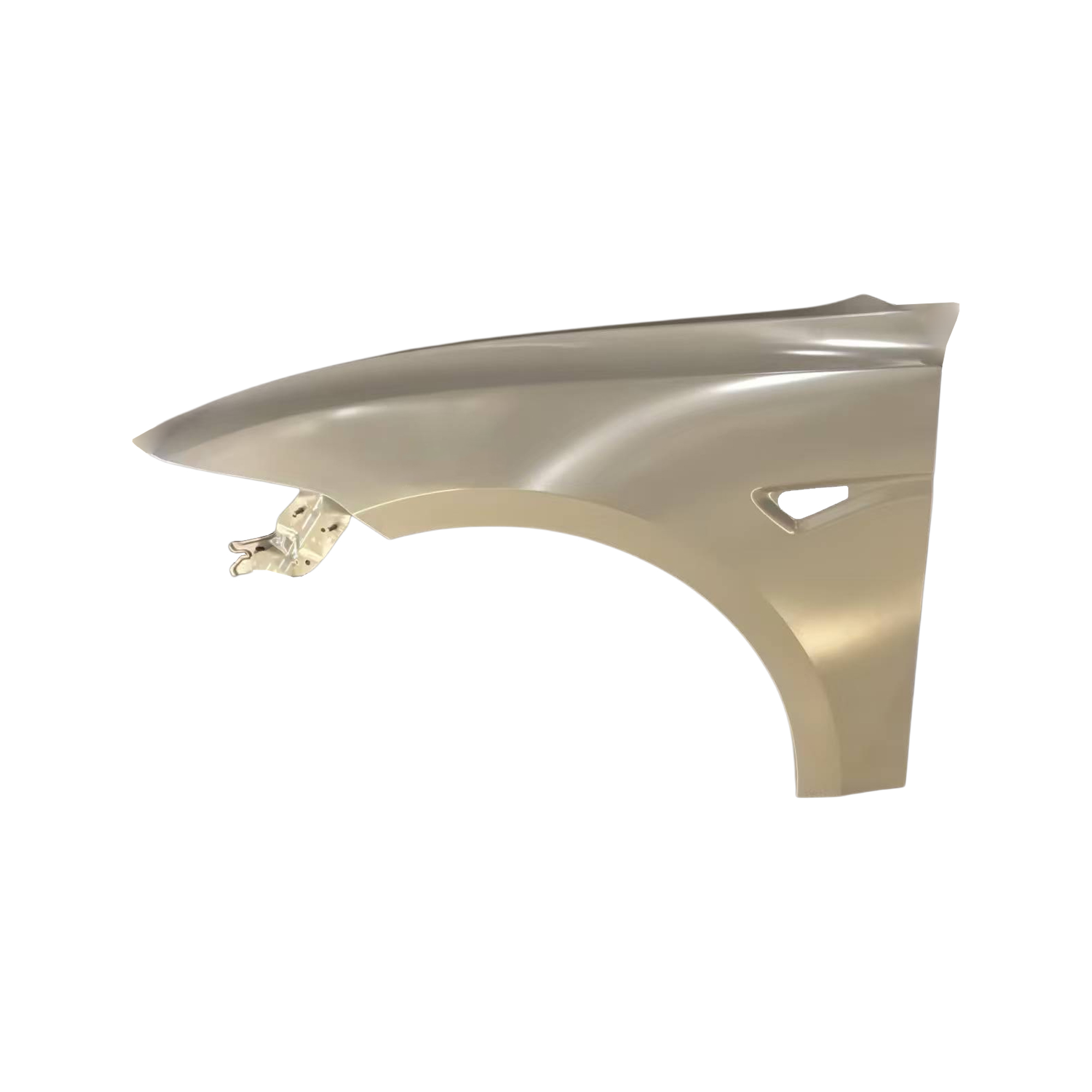

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Tesla Parts Manufacturers and Custom Tesla Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

News Center

Pay Attention To Our Latest News And Exhibitions

Tesla Parts Industry knowledge

The structural components of a Tesla vehicle form the foundational framework of safety. These parts, which include the car's frame, side panels, bumpers, and support beams, are designed with a specific focus on protecting the vehicle’s occupants in the event of an accident. Tesla's design prioritizes the vehicle's ability to absorb impact forces and minimize damage to the passengers, a feature that is fundamental to the brand’s safety reputation. The components that make up the vehicle’s body structure need to be made from materials that offer both strength and flexibility. Tesla uses high-strength steel combined with lightweight aluminum to ensure a strong and durable structure without adding unnecessary weight. The parts we manufacture at Jiangsu Juncheng Vehicle Industry Co., Ltd. contribute to these structural elements, providing precise components that play an essential role in the safety performance of the vehicle. For example, we produce body panels, reinforcement beams, and structural supports, which are fabricated to the highest standards of strength and durability. In the event of a crash, the vehicle’s crumple zones are designed to deform predictably, absorbing impact forces and reducing the amount of energy transferred to the cabin. The components we produce help to ensure that these crumple zones function as intended, playing a critical role in protecting passengers. The vehicle's frame must maintain its integrity even in severe crash scenarios, which is where the high-strength materials used in our manufacturing process make a significant difference. Through advanced production techniques and a deep understanding of automotive safety, we ensure that Tesla’s structural components not only meet but exceed safety standards.

The airbag system in Tesla vehicles is a critical safety feature, working in conjunction with the seatbelt system to protect passengers during a collision. However, the effectiveness of the airbag system depends largely on the reliability of the sensors and the precision with which they are integrated into the vehicle’s overall safety system. Tesla employs an array of sensors, cameras, and accelerometers to detect collisions and determine the force and direction of the impact, triggering the deployment of airbags only when necessary. The components we manufacture for Tesla’s airbag system include the metal brackets, enclosures, and fasteners that hold sensors and other critical elements in place. These parts must be both lightweight and resistant to high levels of stress and temperature changes. Our team at Jiangsu Juncheng Vehicle Industry Co., Ltd. manufactures precision parts that meet these requirements, ensuring that the sensors remain securely in place and continue to function accurately in the event of a collision. Our parts play an important role in the mounting systems for the airbags themselves. The brackets that house the airbags must be precisely engineered to ensure that the airbags deploy correctly and in a timely manner. Even minor deviations in alignment can result in delayed or improper airbag deployment, which can compromise the safety of the occupants. The quality of the components we produce is of utmost importance in ensuring the proper functioning of the airbag system. The wiring and electronic connectors that link the sensors and airbag modules to the vehicle’s central control unit are manufactured to strict tolerances. The reliability of these connectors and wiring harnesses is paramount to the overall functionality of the airbag system, and our high-quality components help ensure that all signals are transmitted accurately and reliably.

Tesla vehicles are renowned for their excellent handling and performance, and much of this comes from the advanced suspension systems used in their vehicles. The suspension system is critical not just for comfort, but also for the car's stability and handling under various driving conditions. Tesla’s suspension system is designed to provide superior ride quality while maintaining excellent handling characteristics, whether in city driving or high-speed maneuvers. The suspension components include control arms, shock absorbers, struts, and springs, which all need to work together to provide a smooth and controlled driving experience. Tesla's unique approach to suspension design combines performance with safety, ensuring that the vehicle remains stable even under extreme conditions, such as emergency maneuvers or during high-speed cornering. These systems also play a role in protecting the battery pack and electric motor by absorbing shock and vibration from the road. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we manufacture several key parts that contribute to Tesla’s suspension performance. We produce control arms and suspension brackets, which need to be both durable and lightweight. These components must be manufactured to very precise specifications to ensure that the suspension system performs optimally. Our parts are designed to handle the stresses and loads associated with Tesla's high-performance electric powertrain, ensuring that the suspension system is capable of maintaining tire contact with the road and providing a safe and stable driving experience. In addition to handling, the suspension system also contributes to the overall safety of the vehicle. In the event of an emergency maneuver, the suspension must be able to handle the forces generated and keep the car stable. By manufacturing suspension parts that meet strict standards of precision and quality, we help ensure that Tesla’s suspension systems deliver both superior performance and safety.

Tesla's braking systems are another key area where performance and safety intersect. The brake system in a Tesla vehicle is designed to ensure that the car can come to a stop quickly and efficiently, while also providing the driver with a responsive and reliable braking experience. Tesla employs a combination of traditional friction braking and regenerative braking to maximize energy efficiency and performance. The regenerative braking system is unique to electric vehicles and helps extend the vehicle’s range by converting kinetic energy back into electrical energy, which is then stored in the battery. However, the friction braking system is still required to provide full stopping power, especially in emergency situations. The brake components we manufacture for Tesla, including rotors, calipers, and hydraulic lines, are designed to handle the high forces and temperatures associated with braking. The brake rotors, in particular, must be made from durable materials that can withstand the heat generated during braking, while also maintaining their structural integrity over time. The calipers and pistons, which apply pressure to the brake pads, need to be precisely engineered to ensure proper braking force is applied evenly across the brake rotor. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we specialize in producing these high-performance brake components, ensuring that they meet the stringent standards required for Tesla vehicles. We manufacture key components in the hydraulic braking system, such as master cylinders and seals, that must be able to withstand high pressures and temperatures without compromising the effectiveness of the braking system. With our focus on precision manufacturing, we help ensure that Tesla's braking systems perform reliably in all driving conditions.

The powertrain of a Tesla vehicle is responsible for converting electrical energy from the battery into mechanical power, which propels the vehicle. Tesla’s powertrains are designed to provide high efficiency, rapid acceleration, and maximum range, making them a key selling point for the brand. However, the powertrain also plays a vital role in the vehicle's overall safety, as the components need to work seamlessly to deliver smooth power delivery while preventing issues such as overheating or short-circuiting. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we produce several critical parts for Tesla’s powertrain, including motor mounts, battery enclosures, and cooling system components. These parts must be manufactured to the highest standards to ensure that the powertrain operates safely and efficiently. For example, the motor mounts must be robust enough to secure the high-powered electric motor, while also minimizing vibration and noise. The battery pack is another critical component of the powertrain that requires careful engineering. Tesla’s battery packs are made up of thousands of individual cells, which must be securely housed to prevent damage or short circuits. We produce the metal enclosures that protect the battery pack, ensuring that the pack is both securely mounted and adequately protected from impact. The cooling system plays a key role in maintaining the battery's optimal operating temperature. We manufacture parts for Tesla’s liquid cooling systems, including heat exchangers and cooling ducts, which help dissipate heat from the battery and motor to ensure safe and efficient operation.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体