Company Profile

Your Trusted Global

Auto Body Partner

Know More

Auto Body Partner

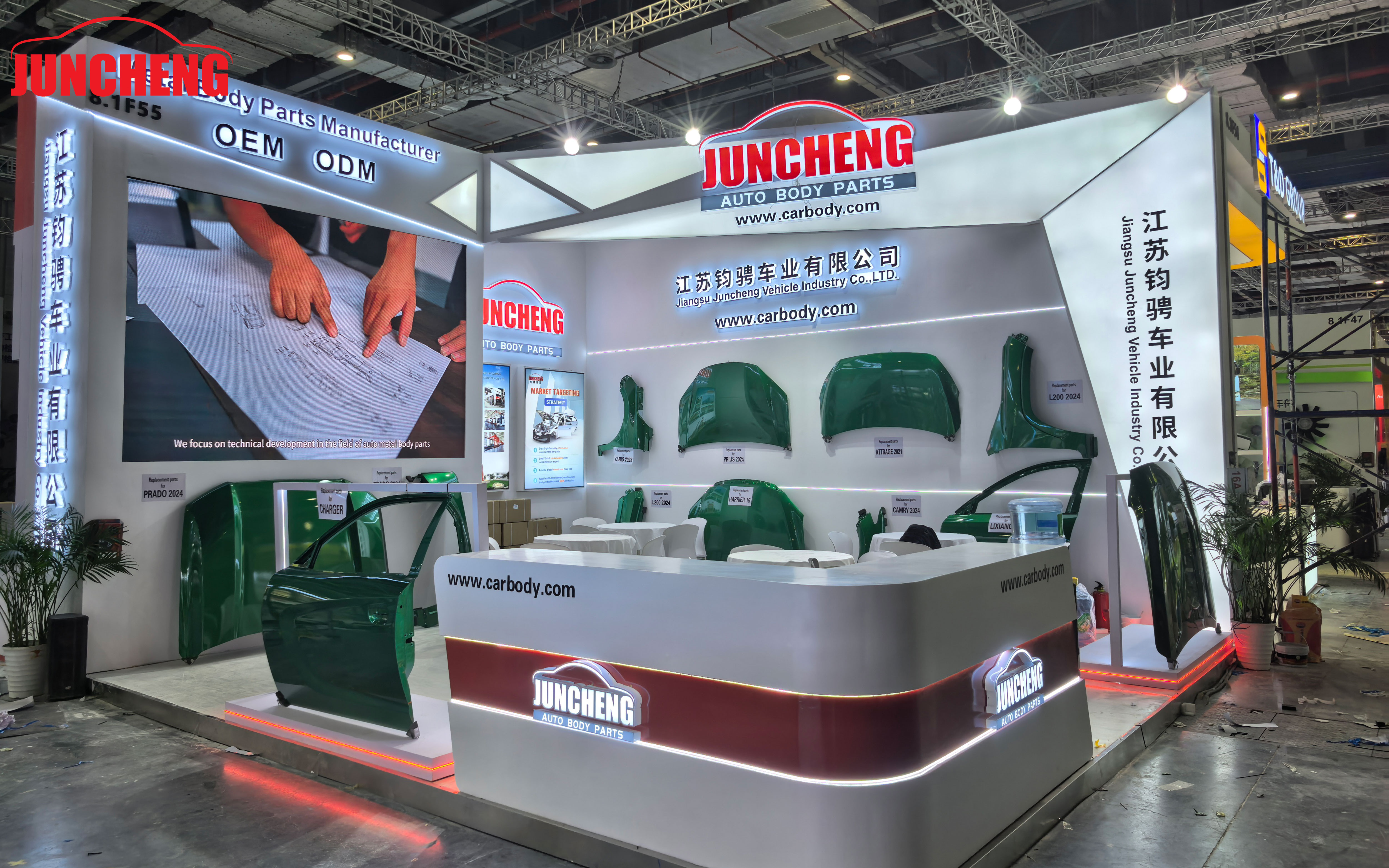

Founded in 2012 and headquartered in Baoying County, Yangzhou, Jiangsu Province, a renowned industrial hub for automotive metal components in China, Juncheng specializes in research and development, precision manufacturing and global distribution of high-quality automotive metal components.

The company is China Gmc Parts Manufacturers and Custom Gmc Parts Suppliers. With advanced production technologies, we are committed to delivering reliable automotive component solutions and continuous innovation, as well as robust quality management systems. Today, Juncheng has established itself as a trusted and influential supplier in the industry.

-

Founded in 0

Founded in 0 -

Country of Sale 0+

Country of Sale 0+ -

Employees 0+

Employees 0+ -

Factory Area 0SQM

Factory Area 0SQM

Our Certificates

News Center

Pay Attention To Our Latest News And Exhibitions

Gmc Parts Industry knowledge

Material selection is the first step in manufacturing GMC parts, and it plays a pivotal role in determining the quality, strength, and durability of the finished products. We take great care in sourcing raw materials from trusted suppliers, ensuring that all metals and alloys used in our components meet the stringent requirements of the automotive industry. The choice of material can vary depending on the specific application and design needs of the part, but it must always align with global quality standards. For instance, we often work with high-strength steel, which is essential for structural components that need to withstand considerable forces, such as chassis or suspension parts. We also source aluminum alloys for lightweight components, which are crucial for improving vehicle fuel efficiency without sacrificing strength. For parts exposed to high temperatures or harsh conditions, such as engine components, we select heat-resistant alloys that can maintain their performance even under extreme conditions. Once the raw materials are chosen, we conduct rigorous testing to ensure they meet the necessary mechanical properties, such as tensile strength, hardness, and corrosion resistance. We also check for compatibility with the design specifications, ensuring that the materials will perform optimally in the final part. This attention to material selection allows us to produce GMC parts that provide excellent performance, longevity, and safety.

The design and engineering phase of GMC parts manufacturing is one of the most intricate steps in the entire process. We employ a team of experienced engineers and designers who work collaboratively with clients to ensure that each component meets their specific requirements. The design process is an iterative one, using advanced computer-aided design (CAD) software to create precise 3D models of the parts. The use of CAD software allows us to visualize the part in great detail, simulate its performance under various conditions, and optimize its geometry. For example, when designing a suspension component, we carefully analyze the part's load distribution to ensure that it can handle the stresses placed on it during vehicle operation. Through simulations, we can also test how the part reacts to factors such as vibration, temperature fluctuations, and external forces. Our engineering team is also tasked with ensuring that the parts are manufacturable at scale while maintaining the highest levels of precision. This requires selecting the right manufacturing methods and ensuring that the design allows for efficient production without compromising the part’s integrity or quality. We take great pride in creating parts that are not only functional but also cost-effective to manufacture, providing the best value to our clients.

After the design phase, the next crucial step is prototyping. Prototypes are essential for validating the design and assessing how the parts will perform in real-world conditions. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we use advanced prototyping methods, including 3D printing and rapid prototyping, to create functional models of the parts. This allows us to quickly and efficiently test the designs before committing to large-scale production. Once the prototype is ready, we conduct a series of tests to ensure that the part performs as expected. These tests include mechanical testing to measure strength, elasticity, and resistance to wear, as well as environmental testing to evaluate how the part reacts to exposure to factors such as moisture, temperature, and UV light. For example, if we are producing an exhaust component, we simulate high temperatures and corrosive conditions to ensure that the part will perform reliably over the long term. We use the prototyping phase as an opportunity to engage with our clients, allowing them to review the prototype and provide feedback. This collaborative approach ensures that the final product will meet the client’s expectations in terms of functionality, fit, and performance. By making necessary adjustments during the prototyping phase, we can minimize the risk of costly design changes later on in the production process.

Precision manufacturing is the backbone of the GMC parts production process. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we invest heavily in advanced manufacturing technologies to ensure that every part we produce meets the highest standards of accuracy and quality. Our state-of-the-art facility is equipped with a variety of machines, including CNC (Computer Numerical Control) machines, die-casting machines, and stamping presses, all of which allow us to produce components with exceptional precision. CNC machining is one of the most important technologies we use, particularly for parts that require tight tolerances and complex geometries. The versatility of CNC machines allows us to produce parts with high accuracy and excellent surface finish. By using multi-axis CNC machines, we can create parts with intricate shapes and precise features that would be impossible to achieve with traditional manufacturing methods. We also employ die-casting for parts that require complex shapes and high production volumes. This method involves injecting molten metal into molds to create intricate designs with minimal waste. For sheet metal components, we utilize stamping presses, which provide a high-speed, efficient means of producing large quantities of parts with uniform quality. These methods allow us to meet both the design specifications and the high-volume demands of the automotive industry. Automated systems also play a significant role in our manufacturing processes. Robotics are integrated into our production lines to perform repetitive tasks such as material handling, welding, and assembly. This not only increases production efficiency but also reduces human error, ensuring a higher level of consistency and precision in every part we produce.

Surface treatment and finishing are critical steps in ensuring the longevity and aesthetic appeal of the GMC parts we produce. We apply various surface treatments to improve the durability, corrosion resistance, and appearance of the components, depending on the material and the application of the part. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we use state-of-the-art technologies to deliver high-quality finishes that meet our clients’ expectations. For parts that require enhanced corrosion resistance, we often apply galvanizing or powder coating. Galvanizing involves coating the part with a layer of zinc to protect it from rust and corrosion, particularly for parts exposed to moisture or harsh environmental conditions. Powder coating, on the other hand, provides a durable and aesthetically pleasing finish, offering both protection against corrosion and a smooth, attractive surface. Anodizing is another surface treatment we use, particularly for aluminum components. This process involves creating a thick oxide layer on the surface of the part, which improves its resistance to corrosion and wear while providing a polished, attractive finish. For parts that require a high degree of wear resistance and aesthetic appeal, we use techniques such as chrome plating or nickel plating, which not only enhance the surface’s appearance but also provide a layer of protection against scratches and damage. These surface treatments serve both functional and visual purposes. Not only do they increase the durability and lifespan of the parts, but they also enhance their appearance, ensuring that our GMC parts are as visually appealing as they are reliable.

After individual components are manufactured, the next critical step is assembly and integration. For many GMC parts, especially those that are part of larger systems such as suspension assemblies, exhaust systems, or engine components, the assembly process must be carefully coordinated to ensure that each part fits and functions correctly within the larger system. At Jiangsu Juncheng Vehicle Industry Co., Ltd., we take great care in assembling complex parts to meet the precise tolerances required by our clients. Our assembly lines are designed to handle a wide variety of components, from smaller precision parts to large structural elements. Skilled technicians oversee the process, ensuring that each part is carefully fitted, connected, and aligned to ensure optimal functionality. Integration involves connecting different parts of the vehicle’s system, such as linking suspension components with the chassis or integrating engine parts with the powertrain. This step requires precision, as even small deviations in alignment or fit can affect the vehicle’s overall performance. Once the parts are assembled, we conduct comprehensive testing to ensure that everything functions as it should. This may involve dynamic testing to assess how the components perform under real-world conditions. We also provide assembly services for custom GMC parts, working closely with our clients to ensure that each custom-built component is integrated seamlessly into the final vehicle design.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体