Our factory has successively introduced 4 domestic and foreign advanced stamping production lines, 4 welding production lines, 1 EDP electrophoresis coating production line, more than 20 ABB robot laser cutting equipment, CMM, salt spray testing machine, tensile testing machine, flaw detection Instrument and other automatic production and processing equipment and advanced testing equipment with an annual output of 1 million sets of body sheet metal production capacity.

Our factory currently has more than 20 experienced engineers and technicians, specializing in technical development in the field of automotive sheet metal.

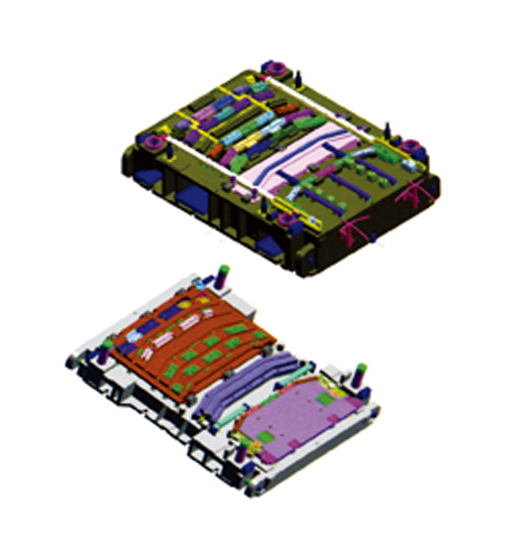

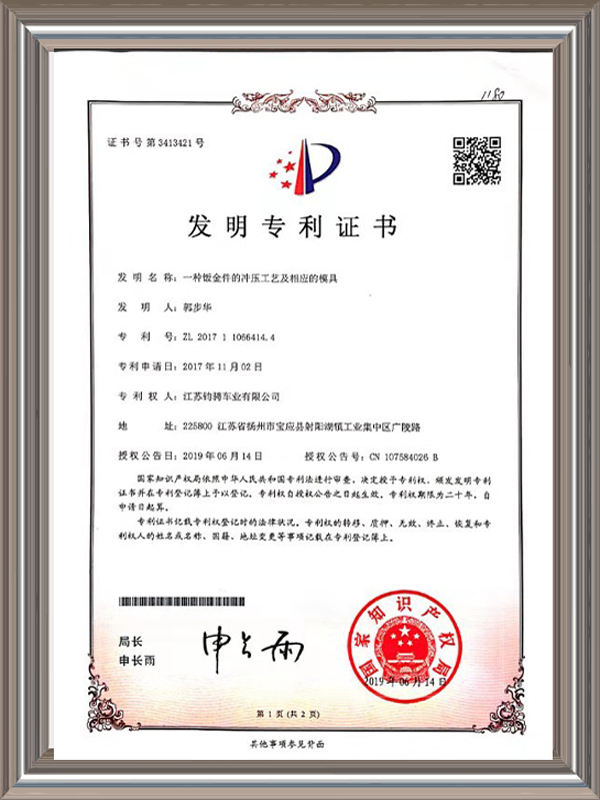

All molds, fixtures and inspection tools are developed, designed and manufactured in-house, with high efficiency, short cycle and excellent quality.

Juncheng has standardized software analysis applications: CATIA design, ALIAS design, CAE analysis, UG mold design, etc.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体