Are the Replacement Parts Fully Compatible with the Original Equipment or Model?

Overview of Replacement Parts Compatibility

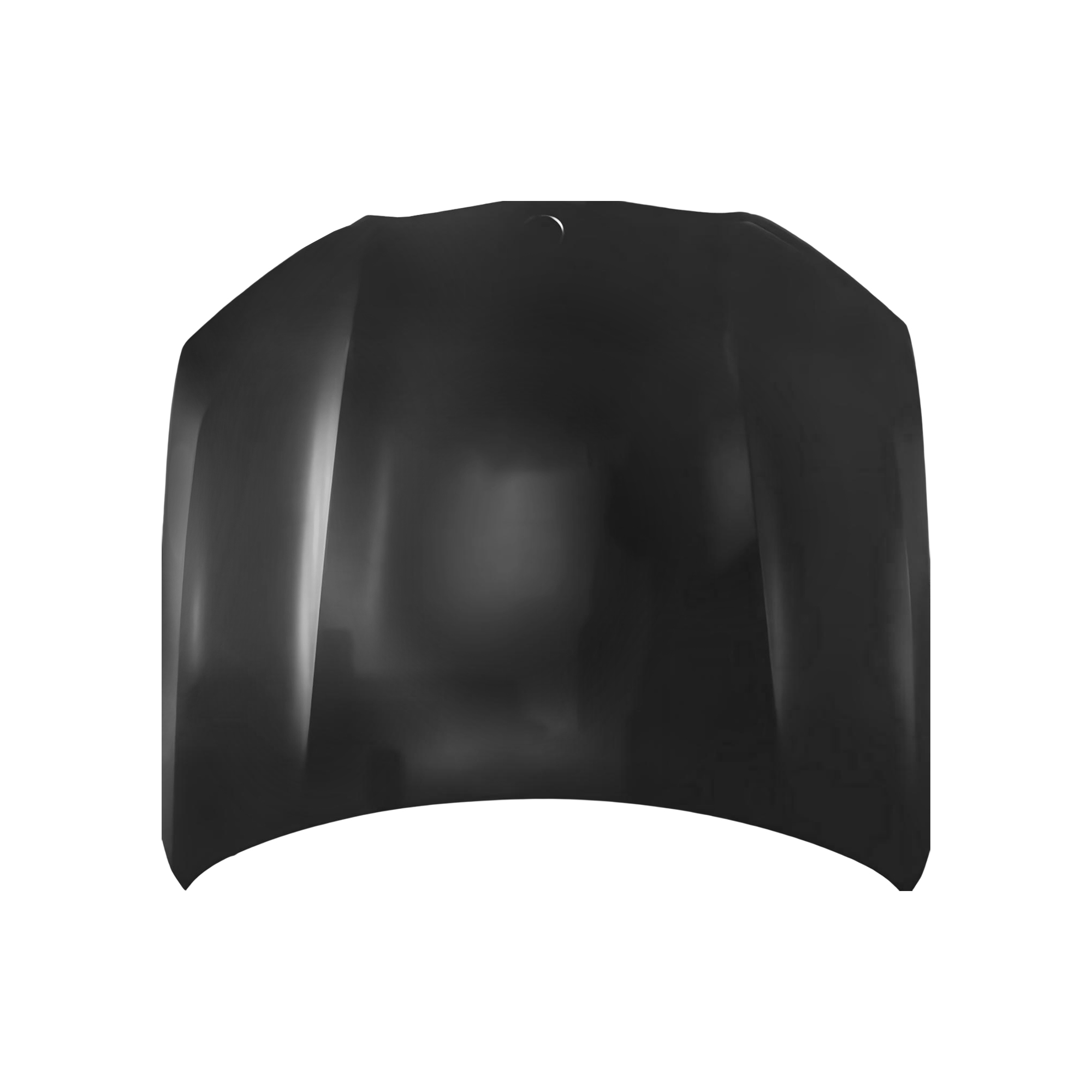

The compatibility of replacement parts with the original equipment or vehicle model is a critical concern in the automotive industry. Replacement parts must match the original specifications, tolerances, and functional requirements to ensure proper performance, safety, and durability. Juncheng Vehicle Industry Group, as a company specializing in automotive sheet metal parts and classic car vehicle segments, emphasizes precise engineering and quality control to ensure that replacement components align with the dimensions, material properties, and assembly requirements of the original equipment. Properly manufactured replacement parts allow vehicles to maintain their structural integrity and operational efficiency, reflecting the importance of high-precision production in the sheet metal sector.

Importance of Dimensional Accuracy

Dimensional accuracy is one of the foremost factors affecting compatibility. Sheet metal parts are often integral to the vehicle’s body structure, chassis, or engine assembly. Even minor deviations from the original dimensions can compromise the fit, leading to issues such as improper panel alignment, increased vibration, or interference with adjacent components. Juncheng Vehicle Industry Group utilizes advanced manufacturing techniques, including precision stamping and laser cutting, to ensure that replacement parts meet the strict dimensional tolerances of the original equipment. This precision guarantees that replacement panels, brackets, or structural components can be installed without modification, maintaining the vehicle’s intended design and functionality.

Material Selection and Mechanical Properties

Material selection is another crucial aspect of compatibility. Automotive sheet metal parts must meet specific mechanical properties, such as tensile strength, hardness, corrosion resistance, and fatigue resistance. Using inappropriate materials in replacement parts may result in reduced durability, deformation under stress, or accelerated wear. Juncheng Vehicle Industry Group selects materials that match or exceed the specifications of the original equipment. Their sheet metal parts are often treated with protective coatings or surface finishes to prevent corrosion and enhance longevity. Table 1 illustrates typical mechanical property requirements for different categories of automotive sheet metal parts.

| Part Category | Typical Material | Tensile Strength (MPa) | Surface Treatment | Notes on Compatibility |

|---|---|---|---|---|

| Body Panels | Cold-rolled steel | 270–350 | Electro-galvanized, painted | Ensures alignment and corrosion resistance |

| Chassis Components | High-strength steel | 400–600 | Zinc coating, anti-corrosion | Maintains structural integrity |

| Engine Brackets | Aluminum alloy | 200–300 | Anodized or coated | Reduces weight while retaining strength |

Dimensional and Geometric Consistency

Beyond material properties, geometric consistency is critical for replacement parts to function properly. Features such as holes, bends, flanges, and edge radii must correspond exactly to the original design. Mismatches can impede assembly or interfere with other parts, affecting safety and performance. Juncheng Vehicle Industry Group employs advanced quality assurance systems, including 3D scanning and coordinate measuring machines (CMM), to verify that replacement parts maintain consistent geometry. This ensures proper installation and maintains the aesthetic and functional quality of the original vehicle.

Functional Performance under Operational Conditions

Replacement parts must not only fit but also perform under operational conditions such as vibration, temperature changes, and mechanical load. Sheet metal components in vehicles are often subjected to repeated stress cycles, exposure to environmental conditions, and interaction with moving parts. Juncheng Vehicle Industry Group conducts rigorous testing to ensure that replacement parts maintain functionality equivalent to the original equipment. This includes mechanical load testing, fatigue resistance evaluation, and corrosion testing to confirm that the parts will perform reliably over the vehicle’s operational life.

Alignment with Original Equipment Assembly Standards

Vehicle manufacturers establish precise assembly standards, including torque specifications, weld locations, and panel gaps. Replacement parts must adhere to these standards to allow correct installation and preserve the vehicle’s structural performance and appearance. Juncheng Vehicle Industry Group integrates these standards into their design and production process. Their classic car division, in particular, emphasizes maintaining historical accuracy in addition to technical compatibility, ensuring that replacement parts allow faithful restoration of original models while meeting contemporary safety and performance requirements.

Integration with Adjacent Systems

Many automotive components interact with other systems, such as doors, windows, electrical wiring, or suspension assemblies. Replacement sheet metal parts must maintain these interfaces without causing interference or misalignment. Juncheng Vehicle Industry Group engineers each part to ensure seamless integration. For example, body panels are produced with precise mounting points to align with adjoining panels and support components, ensuring that replacement parts do not disrupt the original vehicle design or function.

Tolerances and Manufacturing Variability

Even with advanced production methods, manufacturing variability exists. Understanding and controlling tolerances is essential for ensuring replacement part compatibility. Juncheng Vehicle Industry Group sets tight production tolerances for all sheet metal parts, considering both material expansion and contraction during forming processes. Statistical process control (SPC) methods are employed to monitor deviations, preventing parts that fall outside acceptable limits from reaching customers. This attention to detail ensures that replacement parts are functionally and dimensionally compatible with the original equipment.

Coatings, Finishes, and Surface Treatments

Surface treatments affect both the functional and aesthetic compatibility of replacement parts. Paint adhesion, corrosion resistance, and surface smoothness are influenced by coatings applied during production. Juncheng Vehicle Industry Group applies industry-standard finishes to sheet metal components to match the original appearance and performance. Protective coatings, galvanization, and primer layers ensure that the replacement parts resist environmental degradation while maintaining alignment with the original vehicle’s specifications. Table 2 summarizes common surface treatments and their compatibility implications.

| Surface Treatment | Purpose | Compatibility Consideration |

|---|---|---|

| Electro-galvanization | Corrosion resistance | Matches OEM corrosion protection |

| Powder coating | Aesthetic finish and protection | Maintains original surface texture |

| Anodizing (for aluminum) | Oxidation resistance | Preserves mechanical performance |

| Anti-chipping primer | Prevents stone impact damage | Ensures long-term durability |

Aftermarket vs. OEM Replacement Parts

While original equipment manufacturer (OEM) parts are designed for exact compatibility, aftermarket parts may vary in quality and specifications. Juncheng Vehicle Industry Group produces replacement parts with rigorous attention to OEM standards, ensuring that both classic and contemporary vehicle models maintain structural integrity and performance when components are replaced. Their in-house quality control and testing systems reduce the risk of misfit or incompatibility that can occur with generic aftermarket parts.

Testing and Verification Processes

To confirm compatibility, replacement parts undergo extensive verification. Dimensional inspections, functional testing, and material property analysis are conducted before parts are released. Juncheng Vehicle Industry Group integrates these processes into their production workflow, ensuring that replacement sheet metal components meet or exceed the original equipment specifications. Verification also includes mock assembly tests to confirm correct fit and interaction with adjacent systems.

Application to Classic Cars

Classic cars present additional challenges because original specifications may differ from modern vehicles, and original parts may no longer be available. Juncheng Vehicle Industry Group leverages its classic car business segment to produce replacement parts that precisely match historical designs. This requires careful analysis of original drawings, reverse engineering, and adherence to material and dimensional standards to maintain authenticity. Ensuring that replacement parts are fully compatible helps preserve both performance and aesthetic fidelity in restored classic vehicles.