How do Japanese Auto Parts address collision safety requirements?

Collision safety is paramount in modern automotive design, and Japanese Auto Parts' sheet metal design fully considers this. To improve vehicle safety in collisions, especially in critical areas such as the body structure, energy-absorbing zones, and crash beams, Japanese Auto Parts employs a range of advanced technologies and materials in the design and manufacture of its sheet metal parts.

Use of High-Strength Steel: Japanese Auto Parts extensively uses high-strength steel (HSS) and ultra-high-strength steel (UHSS) in its sheet metal parts. These materials provide higher compressive strength, enhancing the vehicle's impact resistance. For example, components such as door frames, chassis, and crash beams typically utilize this high-strength steel, which effectively absorbs energy and disperses impact forces during a collision, reducing the risk of injury to passengers.

Energy Absorption Zone Design: Japanese Auto Parts incorporates specialized energy absorption zones into its vehicle body structure. These zones utilize specially shaped sheet metal parts that deform upon impact, absorbing the impact force and dispersing it to other areas of the vehicle. Particularly in the front and rear energy absorption zones, the metal sheet metal parts are precisely stamped and designed to ensure effective absorption of collision energy, protecting the occupants.

Collapse Simulation and Testing: To ensure the excellent performance of Japanese Auto Parts' sheet metal parts in real-world collisions, Japanese automakers typically conduct rigorous crash simulations and tests. These tests allow manufacturers to optimize sheet metal design, ensuring effective occupant safety under various collision scenarios. These tests include frontal collisions, side collisions, and rollover tests.

Application of Composite Materials: In some high-end or sporty models, Japanese Auto Parts also combines composite materials (such as carbon fiber or aluminum alloy) with traditional metal sheet metal parts. These materials offer superior energy absorption and lightweight properties. In these models, the combination of composite materials and high-strength steel not only enhances the body's impact resistance during collisions but also effectively reduces weight and improves vehicle performance.

Through these measures, Japanese Auto Parts has achieved a globally leading level in ensuring collision safety, guaranteeing the vehicle's safety and stability in the event of a collision.

What are the anti-corrosion treatment technologies used by Japanese Auto Parts for sheet metal parts?

Anti-corrosion treatment is crucial to ensuring the long-term durability of Japanese Auto Parts, especially for exposed metal sheet metal parts, which are susceptible to corrosion from rain, salt spray, and other environmental factors. To improve the corrosion resistance of sheet metal parts, Japanese Auto Parts employs a variety of advanced anti-corrosion technologies.

Hot-dip galvanizing: Hot-dip galvanizing is one of the most commonly used anti-corrosion technologies for sheet metal parts in Japanese Auto Parts. By immersing metal parts in molten zinc, a strong zinc coating is formed on the surface, effectively preventing oxidation and corrosion. Especially in areas such as body shells, chassis, and crash beams, hot-dip galvanizing provides additional protection against external factors such as moisture and salt spray.

Electrophoretic coating (E-Coating): Electrophoretic coating is a highly efficient surface coating method that applies a uniform and robust protective coating to the surface of sheet metal parts. Many sheet metal parts from Japanese Auto Parts, such as interior and exterior body panels and door panels, utilize this technology. Electrophoretic coating uses an electric current to evenly deposit paint, covering hard-to-reach areas of the parts and ensuring effective corrosion protection across the entire surface.

Anodizing: For certain aluminum alloy parts, Japanese Auto Parts employs anodizing. Anodizing forms a hard oxide film on the aluminum alloy surface, improving corrosion resistance, surface hardness, and scratch resistance. Anodized aluminum parts typically have a smoother surface and stronger UV resistance, making them suitable for outdoor and extreme environments.

Liquid Spraying and Phosphating: Spraying technology is also frequently used in sheet metal production, especially for parts with high corrosion resistance requirements. Applying a liquid anti-corrosion coating further enhances the corrosion resistance of sheet metal parts, particularly in environments with high levels of rain and sediment. Furthermore, phosphating is a method of forming a phosphate film on the metal surface, providing additional corrosion protection. Closed-Loop Anti-Corrosion Treatment: Japanese Auto Parts employs closed-loop anti-corrosion treatment technology in some high-end models, especially in seams, bolt holes, and hard-to-reach areas. This technology involves applying special anti-corrosion adhesives or sealants to seams and cavities to prevent moisture and air from entering the parts, thus avoiding internal corrosion.

These anti-corrosion technologies ensure that Japanese Auto Parts' sheet metal parts can withstand harsh environments for extended periods, extending the vehicle's lifespan.

What are the environmental protection measures taken by Japanese Auto Parts in producing sheet metal parts?

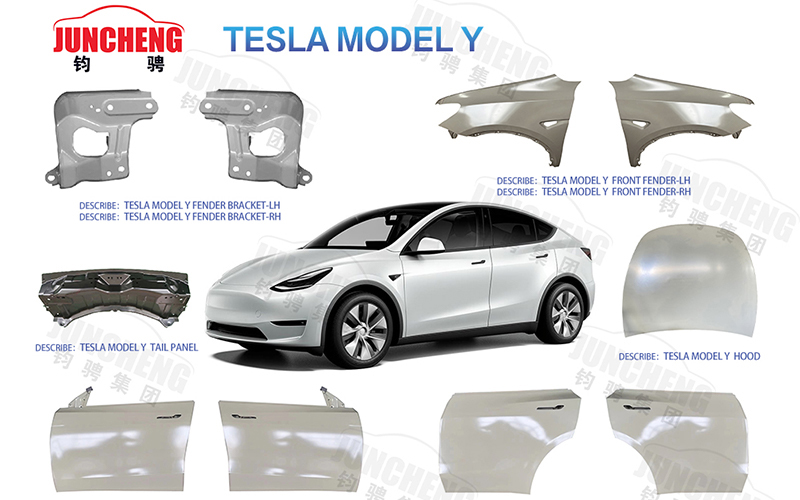

With increasingly stringent global environmental regulations, Japanese Auto Parts has adopted many innovative environmental protection measures in its sheet metal production process to reduce environmental impact and improve resource utilization efficiency. These measures not only help companies meet environmental standards but also promote the sustainable development of the automotive industry. Meanwhile, Jiangsu Juncheng Vehicle Industry Co., Ltd.'s efforts in this regard provide valuable lessons for the Japanese automotive parts industry.

Green Manufacturing Processes: Japanese Auto Parts extensively employs green manufacturing technologies in the production of sheet metal parts. These technologies include automated processes such as efficient stamping, laser cutting, and robotic welding, which minimize material waste and energy consumption during production. To further improve energy efficiency, many automakers have adopted advanced energy management systems in their factories, using intelligent control to reduce unnecessary energy consumption.

Jiangsu Juncheng Vehicle Industry Co., Ltd. has also made significant contributions to green manufacturing. This company focuses on the research and development and production of automotive sheet metal parts, leveraging its technological advantages in vehicle manufacturing to develop efficient and low-energy production processes. By adopting automated and intelligent production processes, Jiangsu Juncheng Vehicle Industry Co., Ltd. has not only improved production efficiency but also reduced waste generation, further lowering carbon emissions.

Lead-Free Soldering and Environmentally Friendly Painting: Japanese Auto Parts widely employs lead-free soldering technology in its sheet metal parts production to meet global environmental requirements. With increasingly stringent environmental regulations, the use of lead-containing materials has been restricted. Japanese automotive parts manufacturers use lead-free solder in their soldering processes, reducing emissions of harmful substances and ensuring worker health and environmental safety.

Regarding painting processes, Japanese Auto Parts also actively adopts low-volatile organic compound (VOC) coatings, reducing air and water pollution during the painting process. Low-VOC coatings reduce the emission of harmful gases into the air while improving coating adhesion and durability, extending the lifespan of parts.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also has an advantage in this regard. As a company specializing in automotive sheet metal parts, Jiangsu Juncheng Vehicle Industry Co., Ltd. is committed to developing environmentally friendly coating technologies and using environmentally compliant paints and welding materials in its production process to reduce environmental pollution. Jiangsu Juncheng Vehicle Industry Co., Ltd. also employs environmentally friendly lead-free soldering processes to ensure its products meet global market environmental requirements.

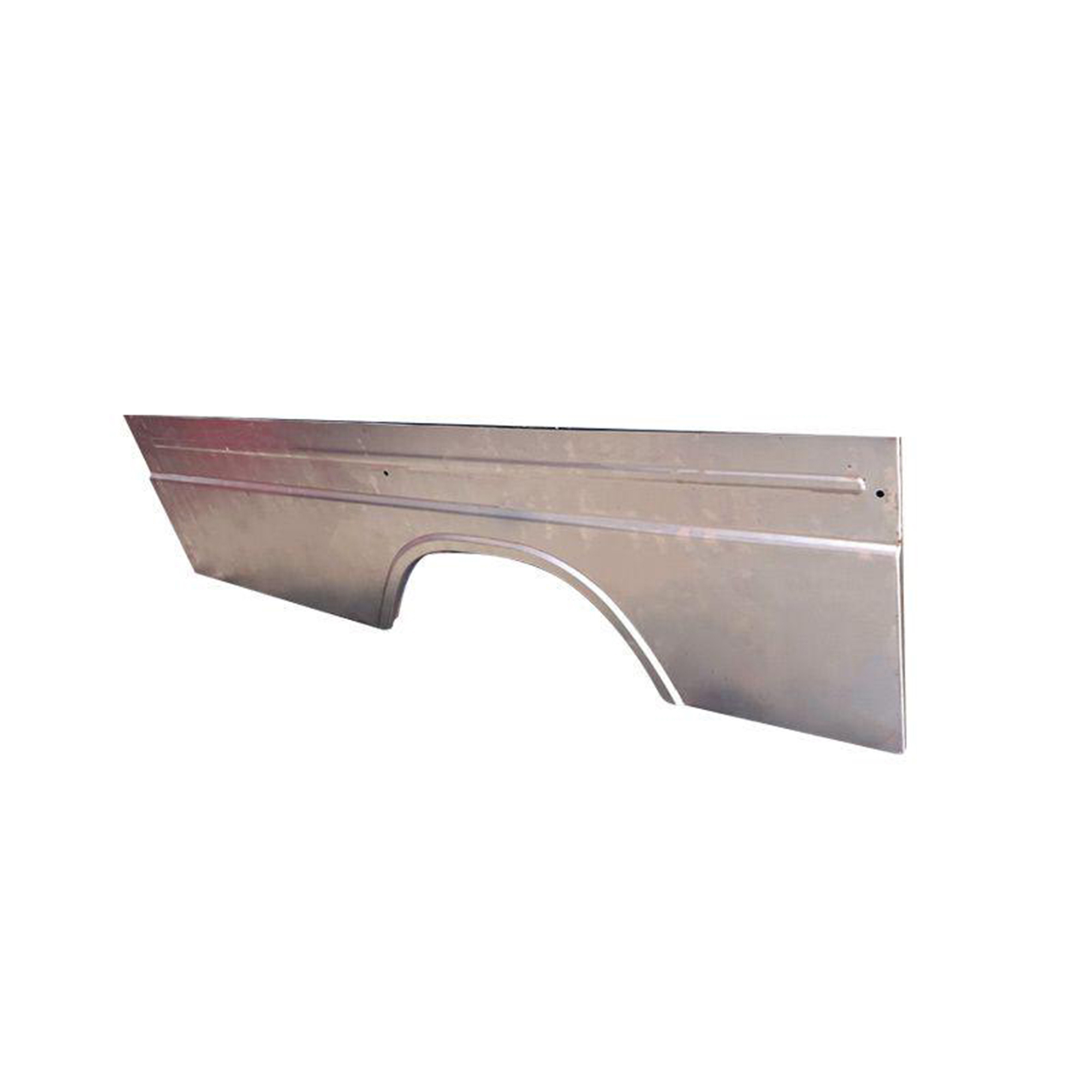

Recyclable Materials and Modular Design: To reduce the consumption of natural resources, sheet metal design in Japanese Auto Parts increasingly emphasizes material recyclability. Materials such as steel and aluminum alloys are widely used in vehicle bodies and chassis; these materials not only have high strength and durability but also high recycling value. Through careful design, many sheet metal parts adopt a modular structure, making it easier to recycle and reuse metal parts when dismantling old vehicles.

Jiangsu Juncheng Vehicle Industry Co., Ltd. also adheres to this philosophy, emphasizing the use of recyclable materials and continuously optimizing its sheet metal design to ensure efficient material recycling at the end of the product's lifecycle. Especially in its classic car restoration business, Jiangsu Juncheng Vehicle Industry Co., Ltd. focuses on using recyclable and environmentally friendly materials for restoration and replacement, providing sustainable restoration solutions for classic car enthusiasts.

Water-based Coatings and Waste Management: Japanese Auto Parts is increasingly using water-based coatings in its painting process. These coatings are not only environmentally friendly but also reduce solvent use and harmful gas emissions. Compared to traditional solvent-based coatings, water-based coatings significantly reduce VOC emissions, helping to improve factory air quality and reduce environmental pollution.

At the same time, Jiangsu Juncheng Vehicle Industry Co., Ltd. also places special emphasis on waste management in its production process. Jiangsu Juncheng Vehicle Industry Co., Ltd. employs an advanced waste recycling system to recycle waste metal and waste paint generated during production, minimizing resource waste. Jiangsu Juncheng Vehicle Industry Co., Ltd. has also implemented strict wastewater treatment and exhaust emission control measures to ensure its production activities comply with environmental regulations.

Low-Carbon Production and Carbon Footprint Control: With increasing environmental awareness, Japanese Auto Parts are also promoting low-carbon production and carbon footprint control. Many Japanese automakers have adopted green energy sources (such as solar and wind power) to reduce carbon emissions in production and have lowered the carbon footprint per unit by optimizing production processes and improving material utilization.

Jiangsu Juncheng Vehicle Industry Co., Ltd. is also actively working to reduce carbon emissions. By introducing advanced production equipment and environmentally friendly technologies, Jiangsu Juncheng Vehicle Industry Co., Ltd. has reduced energy consumption in its production processes and further reduced carbon emissions by optimizing logistics and transportation. This not only aligns with global environmental trends but also enhances Jiangsu Juncheng Vehicle Industry Co., Ltd.'s competitiveness in the international market.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体

.jpg)