How Does German Auto Parts Control Welding Quality and Joint Strength During Production?

Controlling welding quality and joint strength is crucial in the production process of German Auto Parts, especially in the manufacture of body panels and critical structural components. German automakers typically employ advanced welding technologies and rigorous quality control processes to ensure the strength, stability, and durability of welded joints. Here are some key measures German Auto Parts takes in this area:

Robotic Automated Welding: German automakers widely utilize robotic automated welding systems, such as laser welding, spot welding, and arc welding. These high-precision welding processes ensure the uniformity and consistency of welded joints, reducing errors that can occur with human intervention. Automated welding not only improves production efficiency but also ensures the stability of each joint, especially in the welding of materials such as high-strength steel and aluminum alloys.

Laser Welding Technology: For precision joints and high-strength components, German Auto Parts employs laser welding technology, which offers extremely high welding precision and a minimal heat-affected zone, effectively preventing material deformation, shrinkage, and cracking. Laser welding also allows for the welding of thinner metals, reducing material usage without sacrificing strength, thus improving production efficiency and material utilization.

Spot Welding and Continuous Welding Technologies: Spot welding is a common welding method in the production of body structural components. High-end German automakers typically employ continuous spot welding or double-spot welding techniques, providing stronger bonds and ensuring joint strength, especially in high-stress body structural components such as door frames, A-pillars, and B-pillars. These welding processes can withstand strong impact forces, thereby improving vehicle crash safety.

Heat Affected Zone Control: In the welding of high-strength steel (HSS) and aluminum alloy sheet metal parts, German Auto Parts manufacturers focus on controlling the heat affected zone (HAZ). Overheating of the HAS can degrade the metal's properties, affecting the strength of the weld joint. Precise control of welding parameters (such as welding current, time, and speed) effectively avoids overheating and cracking, ensuring joint strength and safety.

Post-Weld Inspection: After welding, German Auto Parts conducts a series of quality inspections, including ultrasonic testing (UT), X-ray testing (RT), and visual inspection, to ensure that each weld joint meets strength and stability requirements. These non-destructive testing techniques allow for the timely detection of potential welding defects and the implementation of necessary corrective measures, ensuring the highest product quality standards.

What Anti-corrosion Treatment Technologies Does German Auto Parts Use?

German Auto Parts employs numerous advanced technologies for anti-corrosion treatment of metal sheet parts during the production process, especially in the production of body and chassis components. Anti-corrosion treatment is crucial for extending the lifespan of vehicles, improving vehicle performance, and reducing maintenance costs. Here are some of the main anti-corrosion technologies:

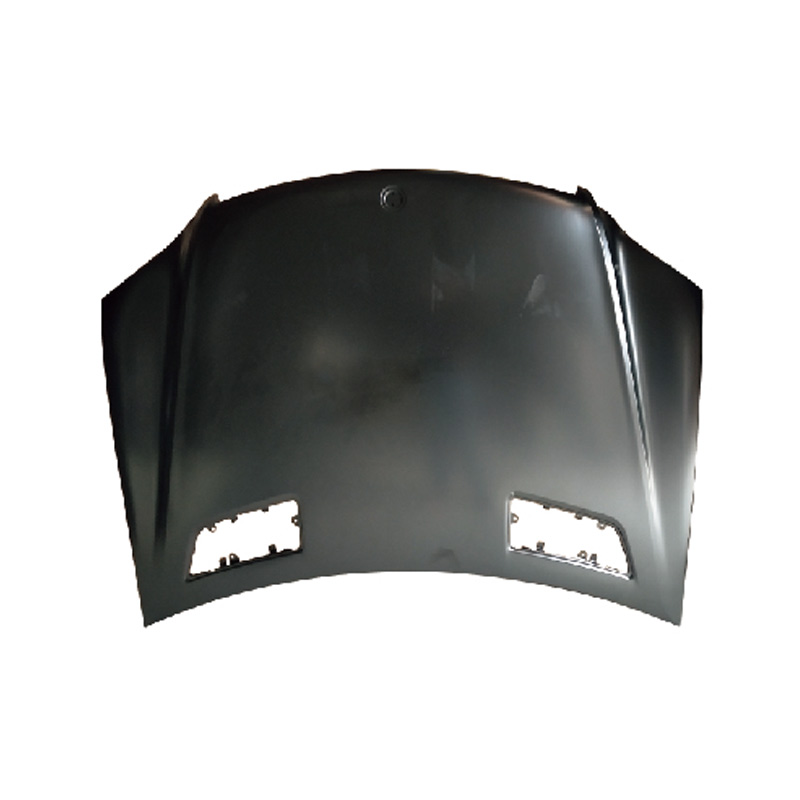

Zincing Technology: German Auto Parts widely uses hot-dip galvanizing and electro-galvanizing technologies to enhance the corrosion resistance of steel components. Hot-dip galvanizing forms a uniform zinc layer on the metal surface, providing strong anti-corrosion protection, especially suitable for components susceptible to moisture and salt corrosion, such as body chassis, door frames, and engine compartments. Electro-galvanizing is mostly used in the production of exterior components, effectively extending their durability while maintaining their aesthetic appeal.

Electrophoretic Coating (E-coating): Electrophoretic coating is an environmentally friendly and efficient coating method, very common in German automotive manufacturing. This process involves immersing sheet metal parts in a paint bath, using an electric current to evenly coat the surface with paint, forming a thin and uniform anti-corrosion coating. The advantages of electrophoretic coating are high adhesion and corrosion resistance, making it particularly suitable for mass production where consistent quality is crucial.

Application of Aluminum and Magnesium Alloys: To further enhance the corrosion resistance of vehicles, German Auto Parts actively utilizes lightweight metals such as aluminum alloys and magnesium alloys. These materials inherently possess excellent corrosion resistance, making them particularly suitable for body structural components, engine compartments, and underbody parts in high-end vehicles. Aluminum alloys not only improve corrosion resistance but also reduce vehicle weight and improve fuel efficiency.

Passivation Treatment: In the manufacturing of certain high-end vehicle components, German Auto Parts also employs passivation treatment technology, especially in the surface treatment of aluminum alloys and stainless steel. Passivation treatment forms an oxide film on the metal surface through a chemical reaction, increasing the material's corrosion resistance while also improving the surface's wear resistance and hardness.

Nano Coating Technology: With advancements in nanotechnology, German Auto Parts has begun employing nano coating technology to provide additional protection for metal surfaces. This coating technology creates an extremely thin protective film on the metal surface, offering longer-lasting corrosion resistance than traditional coatings, especially in harsh weather conditions such as cold, humid, or high-salt environments, significantly extending the lifespan of automotive components.

How does German Auto Parts align its lightweighting efforts with environmental goals?

Lightweighting is not only a key means of improving performance and fuel efficiency in modern automotive manufacturing, but also a core strategy for achieving environmental goals. German Auto Parts reduces vehicle weight by selecting advanced materials, optimizing design, and applying innovative processes, thereby effectively reducing energy consumption and emissions and promoting sustainable development. In this process, the experience and technology of Jiangsu Juncheng Vehicle Industry Co., Ltd. also provide insights for this goal, especially in the lightweight design and environmentally friendly production of sheet metal parts.

A key strategy of German Auto Parts in lightweighting is the use of lightweight materials such as aluminum alloys, magnesium alloys, and high-strength steel (HSS). These materials not only provide sufficient strength but also reduce vehicle weight, thereby improving fuel efficiency and reducing CO2 emissions. In this area, Jiangsu Juncheng Vehicle Industry Co., Ltd., as a professional sheet metal parts manufacturer, also provides lightweight solutions by optimizing sheet metal design and material usage.

Aluminum and Magnesium Alloy Applications: Jiangsu Juncheng Vehicle Industry Co., Ltd. utilizes high-strength aluminum and magnesium alloys in its sheet metal parts supply to multiple automotive brands. The lightweight properties of these materials not only meet environmental protection requirements but also ensure vehicle body strength and safety. Juncheng leverages the advantages of these materials in its custom production of automotive sheet metal parts, helping to achieve a win-win situation for both environmental protection and performance.

High-Strength Steel Applications: Both German Auto Parts and Jiangsu Juncheng Vehicle Industry Co., Ltd. employ high-strength steel (HSS) to reduce the weight of automotive components while maintaining strength and safety. Juncheng's technology maximizes the performance of high-strength steel through precise design and stamping processes, reducing unnecessary material waste and improving production efficiency. This process not only ensures high strength in sheet metal parts but also makes material use more economical and environmentally friendly.

Jiangsu Juncheng Vehicle Industry Co., Ltd., through its modular design of custom sheet metal parts, can precisely design and manufacture automotive components according to customer needs, avoiding overproduction and resource waste. German Auto Parts also places great emphasis on modular design in this area. This design approach not only improves production flexibility but also reduces the number of connections between parts and the use of excessive materials.

Optimized Structure and Shape: Both Jiangsu Juncheng Vehicle Industry Co., Ltd. and German Auto Parts prioritize the structural optimization of sheet metal parts. During the design phase, advanced design tools such as finite element analysis are used to accurately calculate the stress and shape of sheet metal parts, thereby reducing material usage and achieving lightweighting goals. For body components, this structural optimization not only reduces weight but also enhances rigidity and strength, thus improving overall vehicle performance.

Reduced Material Waste: Through modular design, Jiangsu Juncheng Vehicle Industry Co., Ltd. can produce sheet metal parts that meet the needs of multiple vehicle models, making material use more efficient and reducing waste in the production process. German Auto Parts's lightweight design also achieves energy conservation and emission reduction goals by reducing redundant parts and optimizing material ratios.

German Auto Parts places great emphasis on the application of environmentally friendly production processes while implementing lightweight design. By employing low-energy production technologies, green painting processes, and sustainable material usage, they have not only achieved vehicle lightweighting but also minimized the negative environmental impact of the production process. Jiangsu Juncheng Vehicle Industry Co., Ltd. has also adopted similar environmentally friendly production measures.

High-efficiency stamping and hot forming processes: In the production of sheet metal parts, Jiangsu Juncheng Vehicle Industry Co., Ltd. utilizes high-efficiency stamping technologies and hot forming processes. These technologies not only improve production efficiency but also reduce energy consumption and waste generation. For example, hot forming technology heats sheet metal parts at high temperatures, making them easier to shape while maintaining the material's strength and hardness. This technology not only helps Juncheng produce lightweight and high-strength automotive parts but also meets environmental standards, reducing energy consumption.

Green Coating and Surface Treatment: Both German Auto Parts and Jiangsu Juncheng Vehicle Industry Co., Ltd. employ environmentally friendly electrophoretic coating technology. This process uses water-based paints instead of traditional solvent-based paints, reducing the emission of harmful substances. During the coating process, the electrophoretic coating evenly covers the metal surface, providing strong corrosion protection while reducing waste gas and wastewater emissions during production, meeting environmental standards.

Material Recycling and Reuse: Jiangsu Juncheng Vehicle Industry Co., Ltd. also emphasizes waste recycling and reuse, especially in the production of sheet metal parts. Waste is sorted, recycled, and reprocessed, maximizing the use of every inch of raw material. This recycling practice not only reduces resource waste but also lowers the carbon footprint of the production process. Regarding environmental goals, German Auto Parts also achieves efficient material use through a similar resource recycling system.

With the increasing global demand for electric vehicles (EVs), both German Auto Parts and Jiangsu Juncheng Vehicle Industry Co., Ltd. are actively committed to lightweight design for electric vehicles. In electric vehicles (EVs), weight reduction is crucial for increasing driving range and improving energy efficiency.

Customized Sheet Metal Parts for EVs: Jiangsu Juncheng Vehicle Industry Co., Ltd. utilizes lightweight materials and optimized structural designs when producing sheet metal parts for EVs. The lightweight components required for EVs demand higher strength and lower weight. Jiangsu Juncheng Vehicle Industry Co., Ltd. flexibly adjusts designs and uses environmentally friendly materials in the customized production of sheet metal parts for EVs, ensuring compliance with environmental and performance requirements.

Improved Battery Efficiency: By using lightweight metal materials, EVs can reduce the burden on the battery, extend battery life, and improve energy efficiency. Both German Auto Parts and Jiangsu Juncheng Vehicle Industry Co., Ltd. emphasize lightweight design in EVs to support longer driving range and lower energy consumption, which also aligns with the carbon reduction goals of the German automotive industry.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体