Do the alloy materials used in Audi Parts' sheet metal parts possess special corrosion resistance or weather resistance?

Material selection is crucial in the design and production of Audi Parts' sheet metal parts, especially in addressing corrosion and weather resistance during long-term use. Audi utilizes high-performance alloy materials with special corrosion and weather resistance properties to ensure the long-term reliability and safety of its vehicles under various environmental conditions.

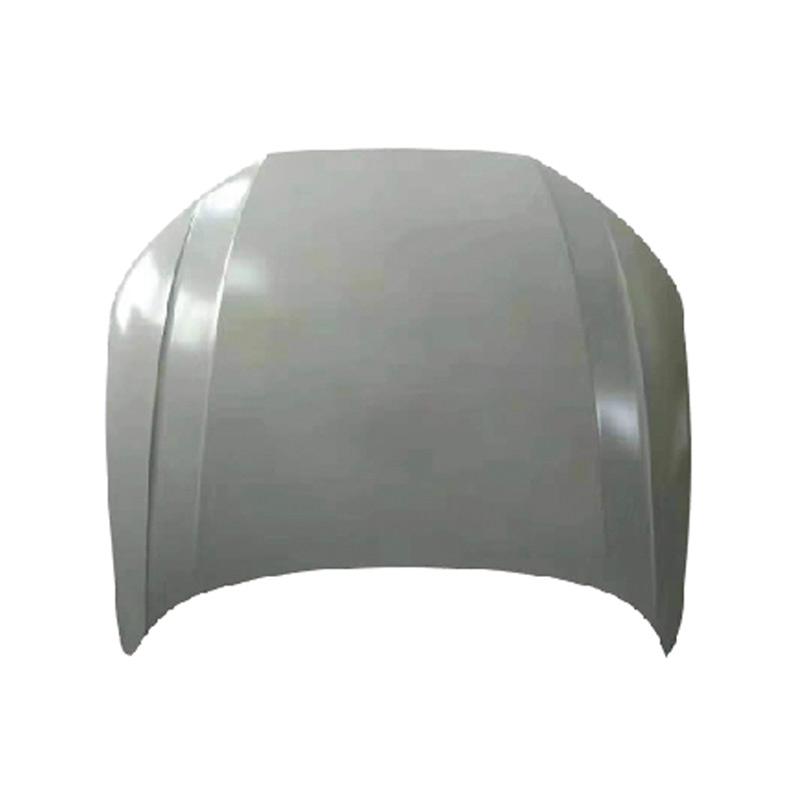

Application of Aluminum Alloys: To meet high strength requirements and reduce vehicle weight, Audi Parts uses aluminum alloys in many sheet metal parts. Aluminum alloys not only have a lower density, helping to reduce vehicle weight, but also excellent corrosion resistance, especially in humid and salt spray environments. Furthermore, the natural oxide layer of aluminum alloys provides a protective barrier, effectively preventing corrosion.

Galvanized Steel and Aluminized Steel: For components requiring higher strength, such as the body frame and chassis, Audi Parts commonly uses galvanized steel and aluminized steel. These materials have a zinc or aluminum coating applied to their surface to increase their corrosion resistance, especially in humid and acidic environments. This method allows Audi Parts metal sheet metal parts to better resist corrosion from the external environment, extending their service life.

Weather-resistant coatings: To further enhance corrosion resistance, Audi also applies special weather-resistant coatings to the metal surfaces. These coatings not only effectively prevent the penetration of salt and moisture but also withstand the challenges of UV radiation and temperature changes, thereby improving the durability of the sheet metal parts. Audi Parts also employs electrophoretic coating (EPD) technology, which evenly distributes the protective film during the coating process, enhancing its protective effect.

Key Technologies:

Use of materials such as aluminum alloys and galvanized steel.

Surface treatment technologies: galvanizing, aluminizing, thermal spraying, weather-resistant coatings.

Electrophoretic coating (EPD) improves coating uniformity and corrosion resistance.

What welding technologies are used in Audi's sheet metal parts production to ensure the strength and stability of the joints?

Welding technology is crucial in the production of Audi Parts sheet metal parts because it directly affects the strength, stability, and safety of the vehicle body. To ensure high-quality joints and stability, Audi employs a variety of advanced welding technologies.

Laser Welding: Laser welding technology is widely used in Audi Parts' high-end models, especially in joining aluminum alloy sheet metal parts. Laser welding provides high-precision weld points, and the relatively low heat input during the welding process reduces the risk of material deformation. This makes laser welding an ideal choice for joining lightweight alloy materials (such as aluminum) and high-strength steel. Laser welding not only ensures the strength of the joints but also reduces stress generated during welding, contributing to improved overall vehicle body stability and safety.

Spot Welding: Spot welding is one of the traditional sheet metal welding methods, particularly suitable for steel body components. Audi Parts utilizes high-precision spot welding technology in steel welding to ensure the strength and durability of each weld. By optimizing welding parameters, Audi reduces the heat-affected zone, preventing weld cracking or corrosion and improving vehicle body safety.

Friction Stir Welding (FSW): For some high-strength, difficult-to-weld materials, Audi Parts also employs friction stir welding technology. This technology allows welding at lower temperatures, avoiding the welding deformation problems common in traditional welding, and is particularly suitable for joining lightweight materials such as aluminum alloys. Friction stir welding technology generates frictional heat at the welding point through a rotating tool, ensuring a high-strength connection between the two materials.

Laser-Friction Welding Combination Technology: To further improve welding efficiency and precision, Audi employs laser-friction welding combination technology in some high-end models. This combination method ensures the strength of the weld joint while increasing welding speed and reducing production time.

Key Technologies:

Laser Welding (for high-precision, lightweight material joining).

Spot Welding (traditional steel joining).

Friction stir welding (suitable for high-strength alloy materials).

Laser-friction welding combined technology (improves efficiency and precision).

How does Audi integrate sustainability into its parts manufacturing process?

In the production of Audi Parts, Audi consistently prioritizes sustainability as a core objective, particularly in the production of sheet metal parts. Through environmentally friendly processes, material recycling, and efficient energy management, Audi strives to reduce its environmental impact in automotive production and maximize product lifecycles. Similar to Jiangsu Juncheng Vehicle Industry Co., Ltd.'s technological control philosophy in sheet metal parts production, Audi rigorously controls every stage of its production process to ensure parts quality while minimizing its environmental burden.

Advanced Material Selection and Recycling: In the production of sheet metal parts, Audi uses materials with high recycling value, such as aluminum alloys and galvanized steel. These materials are not only lightweight and high-strength but also possess excellent corrosion resistance, ensuring the long-term durability of vehicles. Similar to Jiangsu Juncheng Vehicle Industry Co., Ltd., which also rigorously selects environmentally compliant materials and efficiently recycles and reuses waste during production, thereby reducing resource waste and achieving a circular economy.

Audi also collaborates with suppliers to ensure that materials in its supply chain meet environmental standards and prioritizes the use of renewable materials, such as components derived from recyclable aluminum and steel.

Green Manufacturing Processes and Energy Efficiency Optimization: Audi employs advanced technologies such as laser welding, spot welding, and friction stir welding to ensure that each weld is not only precise but also reduces energy waste. These technologies minimize energy consumption and material waste during manufacturing. Jiangsu Juncheng Vehicle Industry Co., Ltd. has also optimized stamping, welding, and surface treatment processes in production, strictly controlling every step to ensure high precision and strength while reducing costs and shortening delivery times, and ensuring an environmentally friendly production process.

Audi's production lines also optimize energy use through high automation. Similar to Jiangsu Juncheng Vehicle Industry Co., Ltd., Audi ensures the use of energy-saving technologies in its production equipment, thereby reducing its environmental impact throughout the production process.

Low Carbon Emissions and the Use of Renewable Energy: Audi Parts not only employs efficient process control in its production processes but also actively promotes low-carbon production within its facilities. Audi has implemented the use of renewable energy sources, such as wind and solar power, at multiple production sites worldwide to reduce greenhouse gas emissions. Jiangsu Juncheng Vehicle Industry Co., Ltd. similarly emphasizes energy management, reducing carbon emissions by optimizing energy use within its factories and minimizing energy waste through refined production control.

In addition to using clean energy, Audi is committed to reducing wastewater and exhaust emissions from its automotive production processes globally, and all its production facilities meet global environmental standards. Similarly, Jiangsu Juncheng Vehicle Industry Co., Ltd. strictly adheres to environmental regulations and invests resources in optimizing waste management during the production process.

Component Lifecycle Management: In Audi's component lifecycle management, Audi Parts places particular emphasis on ensuring environmental compliance at every stage, from raw material procurement to finished product completion. Audi not only uses environmentally friendly materials during the design phase but also implements an effective recycling system during vehicle retirement, ensuring the reuse of parts such as sheet metal components.

Jiangsu Juncheng Vehicle Industry Co., Ltd., as a component supplier, also strictly controls material recycling and reuse. In Jiangsu Juncheng Vehicle Industry Co., Ltd.'s sheet metal component production, every step of the material handling process is precisely controlled, ensuring the quality and environmental performance of the final product while significantly reducing production costs and improving production efficiency.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体

.jpg)

.jpg)

.jpg)