How do you guarantee that Ford parts will not be damaged during transportation?

Transport Challenges for Ford Parts

Transportation of Ford parts involves various risks including vibration, impact, moisture exposure, and surface abrasion. These risks are particularly relevant for sheet metal components, structural reinforcements, exterior panels, and precision-formed parts such as hoods, fenders, door skins, rocker panels, and brackets. Since Ford models vary widely in size and structural layout, packaging and transportation must be tailored to the geometry and sensitivity of each component. Juncheng Vehicle Industry Group, a company specializing in the research, development, production, and sales of automotive sheet metal parts, integrates engineering principles into packaging design and logistics management. With experience supplying sheet metal components and operating a complete vehicle business segment for classic cars, the company has accumulated knowledge on preventing deformation or surface damage during long-distance transport. Understanding the transport risks and the characteristics of Ford parts allows the company to design specific protective solutions that support stable logistics operations.

Customized Packaging Designs Based on Part Characteristics

To prevent damage during transportation, packaging must reflect the shape, material thickness, and surface treatment of each Ford component. Sheet metal parts require support structures that maintain rigidity and prevent bending under external pressure. Juncheng Vehicle Industry Group adopts customized packaging models designed according to dimensional drawings and compatibility requirements. For example, long structural components such as side beams or sill reinforcements benefit from wooden or composite frames that stabilize the part and distribute tension evenly. Exterior panels such as fenders or door skins are packaged with layered padding materials to prevent surface abrasion. By designing packaging solutions around each part’s geometry, the company ensures that Ford parts remain protected throughout handling, loading, and transport.

Selection of Protective Materials to Reduce Impact and Vibration

The materials chosen for packaging play a significant role in preventing damage. Foam inserts, honeycomb paper structures, corner protectors, and anti-scratch films are commonly used to provide cushioning and prevent movement inside the packaging. Juncheng Vehicle Industry Group selects materials that balance protective performance, cost efficiency, and environmental considerations. For Ford sheet metal parts, vibration control is important because continuous shaking during transport may cause micro-deformation or edge distortion. Protective materials are arranged in layers, allowing the cushioning system to absorb impact forces and reduce stress applied to the part. Consistent evaluation of these materials helps the company maintain stable protection standards and respond to the varying requirements of different Ford models.

Reinforced Crates and Structural Supports for Large Components

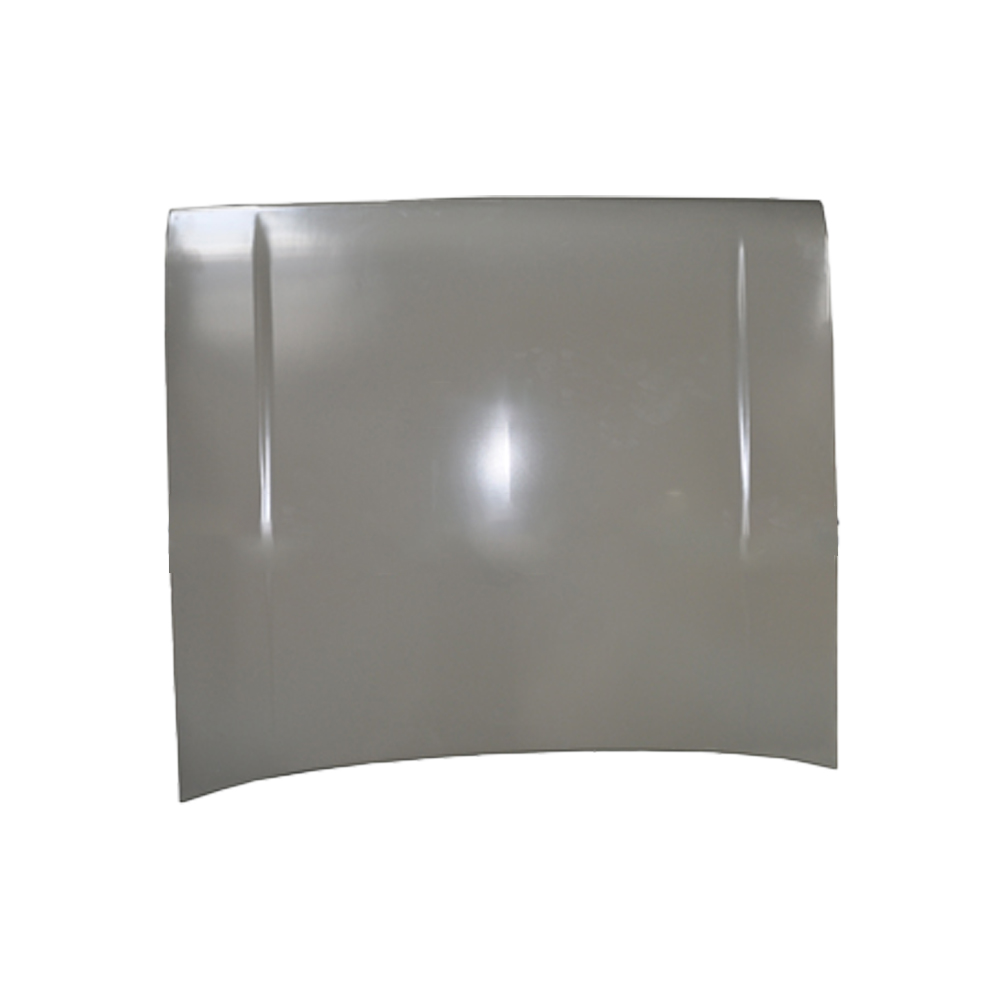

Large Ford parts such as hood assemblies, tailgates, and front-end structures require reinforced crates capable of sustaining weight and preventing deformation. The design of these crates often incorporates cross-bracing, pallet-integrated bases, and securing straps. Juncheng Vehicle Industry Group manufactures or sources crates that match the size and load-bearing requirements of each part. Inside the crates, fixed brackets positioned according to Ford part geometry prevent lateral movement. This ensures that even during long-distance shipping, components remain firmly stationed and avoid collision with crate walls. The use of reinforced crates is particularly valuable for exporting large sheet metal components, as they provide stability across varying transport conditions.

Moisture and Corrosion Prevention Measures

Transit environments often expose packages to fluctuating humidity levels. For sheet metal Ford parts, moisture may lead to surface oxidation or corrosion if not properly controlled. Juncheng Vehicle Industry Group implements anti-corrosion strategies such as applying rust-preventive coatings, sealing packaging with moisture-proof films, and placing desiccant packets inside crates. These measures ensure that humidity remains at a stable level during shipping. Additionally, sealed packaging reduces the risk of condensation forming on the surface of parts when crossing regions with temperature differences. By controlling moisture exposure, the company helps maintain the integrity of Ford sheet metal components throughout the logistics cycle.

Shock-Absorbing Palletization Techniques

Correct palletization contributes significantly to transportation safety for automotive parts. Pallets must support the weight of the cargo while minimizing bending or shifting during forklift movement. Juncheng Vehicle Industry Group uses shock-absorbing pallet materials and ensures that Ford parts are placed in positions that distribute load evenly. Straps, corner locks, and anti-slip pads keep packages stable even when moved repeatedly. Proper pallet planning also improves loading efficiency, reducing the chance of misalignment or accidental impact during warehouse operations. By integrating shock-absorbing palletization into the logistics workflow, the company maintains transportation stability over land and sea routes.

Quality Control and Inspection Before Shipment

Before a shipment is dispatched, inspection procedures verify that the packaging meets protective standards and that the parts inside are free from defects. Juncheng Vehicle Industry Group implements a multi-stage inspection process that evaluates crate integrity, internal cushioning, and part positioning. Engineers check for gaps, exposed edges, or loose materials that may cause damage in transit. For orders containing multiple Ford parts, spacing and stacking policies ensure that weight distribution does not lead to stress on lower layers. Inspection results are documented and archived, supporting traceability and continuous improvement in logistics quality.

Logistics Handling Standards and Training

Even the best packaging systems may not fully prevent damage if handling procedures are not followed. Training logistics personnel is therefore an essential part of damage prevention. Juncheng Vehicle Industry Group provides instructions on lifting techniques, forklift safety, cargo placement, and load balance management. Workers are trained to avoid placing pressure on sensitive areas such as curved surfaces or attachment points. They also learn to identify warning labels, handle moisture-sensitive parts, and secure cargo properly within transport vehicles. These handling standards, when followed consistently, help reduce accidental damage caused by improper loading or unloading.

Transport Route Evaluation and Carrier Selection

Transport conditions vary depending on the route, carrier, and mode of shipping. Selecting appropriate carriers helps minimize exposure to harsh conditions or excessive vibration. Juncheng Vehicle Industry Group evaluates transport routes based on road quality, climate, transit time, and the risk of mechanical shock. For long-distance shipments involving Ford parts, the company may choose carriers with specialized equipment or temperature-controlled environments. Route evaluation also involves assessing locations where cargo may undergo multiple transfers, as each transfer increases the chance of mishandling. Through careful route planning, the company creates a logistics strategy that aligns with the sensitivity of Ford parts.

Use of Impact Indicators and Monitoring Devices

Modern logistics practices incorporate monitoring devices that record handling impact, tilt angle, and temperature. Juncheng Vehicle Industry Group uses such indicators when transporting parts that are particularly sensitive to shock or orientation. For instance, large sheet metal assemblies or components with geometry prone to bending benefit from tilt indicators and shock sensors that provide visual evidence of whether the cargo has been subjected to abnormal conditions. These indicators help both the company and the customer verify that transportation requirements were followed and offer valuable data for continuous improvement.

Integration of Engineering Expertise Into Packaging Optimization

Since Juncheng Vehicle Industry Group specializes in automotive sheet metal parts, its engineering capabilities extend beyond manufacturing into packaging design. Engineers analyze material strength, surface finishing, and structural flexibility to tailor protective solutions for Ford components. This approach ensures that packaging is not generic but rather informed by technical understanding of the parts. The company’s experience in classic car complete vehicle operations further enhances its insight into protecting valuable and sometimes rare components. These engineering-based optimizations help maintain part integrity and reduce the frequency of transport-related claims.

Cost–Protection Balance in Packaging Strategies

Protection must be balanced with cost efficiency in order to maintain competitiveness in the automotive supply chain. Over-packaging increases transportation costs, while insufficient protection risks damage and product rejection. Juncheng Vehicle Industry Group evaluates material usage, crate design, and container layout to develop balanced solutions. For Ford parts, this balance ensures that both common components and high-value sheet metal parts receive suitable protection without unnecessary material consumption. The following table illustrates how packaging strategies are balanced between protection level and cost considerations:

| Protection Strategy | Protection Level | Cost Impact | Typical Application |

|---|---|---|---|

| Multi-layer foam padding | High | Medium | Small exterior panels |

| Reinforced wooden crates | High | High | Large structural parts |

| Moisture-proof sealing | Medium | Low | Sheet metal surfaces |

| Anti-scratch films | Medium | Low | Painted or coated parts |

| Shock-absorbing pallets | Medium to High | Medium | Bulk shipments |

Coordination With Customers During Shipment Preparation

Clear communication with customers ensures that packaging and transport arrangements meet expectations. Juncheng Vehicle Industry Group provides customers with packaging specifications, crate dimensions, and part protection details before shipment. Customer requirements regarding stacking limits, moisture sensitivity, or delivery conditions are incorporated into the logistics plan. This coordination reduces misunderstandings and aligns both parties on responsibilities during the shipping process. For shipments of Ford parts that require special handling, the company confirms details such as preferred carriers, customs documentation, and inspection requirements to support smooth delivery.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体