If the Customer Provides the VIN Code, Could You Help Confirm Whether the Dodge Parts Are Compatible?

Understanding the Function of the VIN in Parts Compatibility

The Vehicle Identification Number (VIN) is a structured code uniquely assigned to each vehicle, enabling precise identification of manufacturing details, configuration, and production variations. When customers inquire whether Dodge parts are compatible, the VIN becomes a foundational reference that enhances accuracy in parts matching. For Dodge vehicles, especially models that span multiple production years or carry trim variations, small differences in engine design, electrical components, body panels, or structural reinforcements can influence compatibility. Juncheng Vehicle Industry Group, which specializes in the research, development, production, and sales of automotive sheet metal parts, relies on the VIN as a technical indicator to examine parameters such as production site, equipment version, and configuration differences. This approach supports a more reliable assessment of whether a replacement part aligns with original specifications. The VIN therefore functions as an essential verification tool, reducing the risk of selecting an unsuitable component and promoting efficient communication between suppliers and end users.

Why VIN-Based Verification Is Essential for Dodge Models

Dodge vehicles cover a broad lineup of sedans, SUVs, and performance-oriented models, each potentially containing different structural designs based on year or production batch. Even when the exterior design appears similar, interior components, reinforcement plates, mounting points, and sheet metal geometries may differ. Dodge models such as the Charger, Challenger, Durango, and Ram series often undergo mid-cycle upgrades, which influence part specifications. By using VIN data, Juncheng Vehicle Industry Group can accurately identify these subtle but important distinctions. This method minimizes uncertainties that arise from visual inspection or general model descriptions, which are often insufficient for determining exact part compatibility. As a company engaged in sheet metal parts production and equipped with extensive experience in manufacturing and supplying components for automotive applications, Juncheng uses VIN analysis to align products with precise Dodge requirements and to support high manufacturing accuracy.

Key VIN Segments Relevant to Dodge Parts Confirmation

For compatibility verification, not all VIN characters carry the same level of relevance. Specific positions in the VIN encode the model series, engine type, body configuration, restraint system details, and manufacturing location. These elements directly influence part selection, especially in sheet metal components, exterior trims, or mounting structures. Juncheng Vehicle Industry Group, which has a strong engineering and production background, interprets these segments to identify distinctions such as steel grade variation, panel thickness, frame dimensions, and hole positioning. The following table summarizes several common VIN segments and their primary uses in parts compatibility checking:

| VIN Segment Position | Information Category | Relevance to Dodge Parts Selection |

|---|---|---|

| 1–3 | Manufacturer & region | Determines production site standards and regulatory variations |

| 4–8 | Vehicle attributes | Identifies body type, restraint systems, engine model, and structural layout |

| 9 | Check digit | Confirms VIN validity to avoid data errors |

| 10 | Model year | Distinguishes design updates or structural revisions |

| 11 | Assembly plant | Identifies manufacturing differences between plants |

| 12–17 | Serial number | Specifies production batch variations |

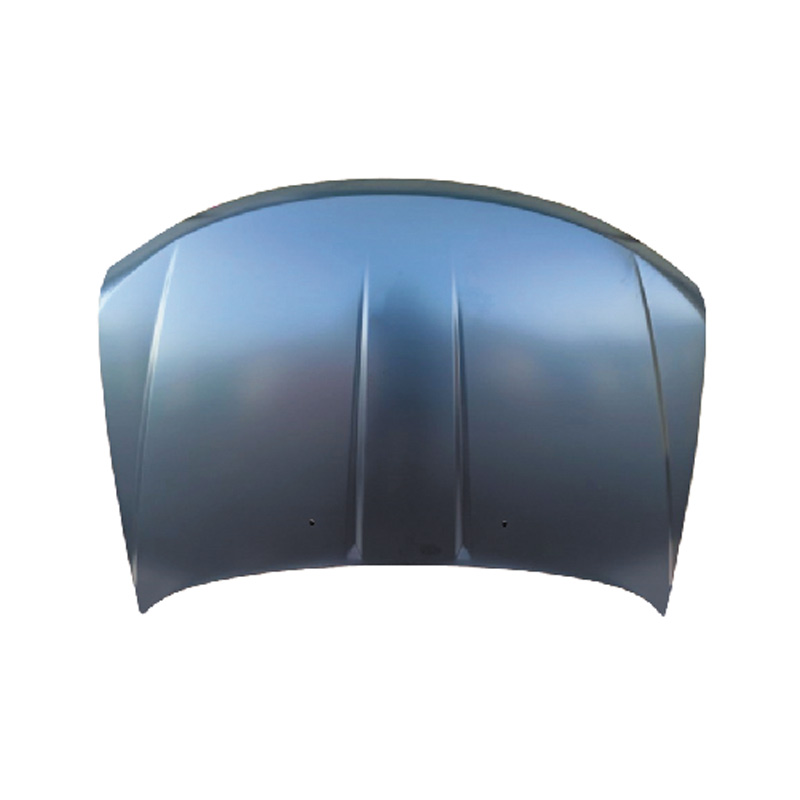

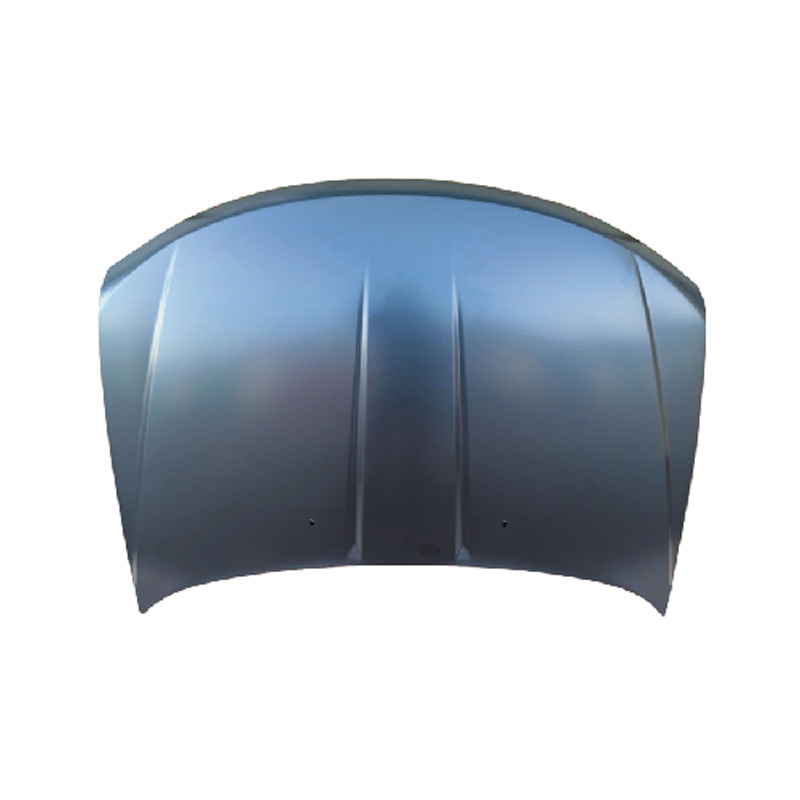

Applications of VIN Verification for Sheet Metal Components

For sheet metal components such as fenders, hoods, doors, reinforcements, rocker panels, and underbody structures, even minor design changes can affect installation compatibility. Dodge vehicles often incorporate model-specific geometric shaping, weld positioning, and reinforcement layouts, making generic part matching risky. Juncheng Vehicle Industry Group, which has extensive expertise in producing automotive sheet metal parts, analyzes the VIN to confirm whether the structural layout corresponds with the intended replacement part. For example, a Dodge Charger rear fender from a specific year may include an updated curvature or flange thickness that differs from earlier versions. Using the VIN, engineers can identify such revisions and ensure the selected part aligns with the original characteristics. This process enhances fitment quality, reduces installation adjustment needs, and strengthens the reliability of replacement parts across manufacturing batches.

VIN Usefulness in Identifying Structural and Safety-Related Components

Safety-related parts such as bumper beams, crumple zones, side intrusion beams, and subframe components require accurate matching due to their influence on vehicle integrity. VIN-based verification allows suppliers to identify whether a Dodge model uses a particular reinforcement structure, thickness specification, or mounting point arrangement. Juncheng Vehicle Industry Group applies engineering analysis when interpreting this data to ensure that sheet metal parts used in structural zones meet design intentions. Incorrectly matched safety components can impact energy absorption performance, and VIN data helps avoid such risks by providing clarity on body type variations and safety equipment configurations. This enables accurate identification of compatible parts and supports the vehicle’s designed safety performance.

Using VIN Data to Distinguish Trim-Level Variations

Trim levels within Dodge models introduce variations in attachments, mounting brackets, and accessory compatibility. A Dodge Durango with a performance package may include alternative engine mounts, different cooling layouts, or revised hood structures. VIN verification helps confirm these trim distinctions, preventing the use of parts designed for a different specification level. For Juncheng Vehicle Industry Group, incorporating VIN-based interpretation into product matching helps align sheet metal components and accessory mounting points with the correct trim level. This approach reduces the errors that may arise when trim features are identified solely by external appearance or customer descriptions.

Ensuring Compatibility for Classic Dodge Vehicles

Older Dodge models or those with long production histories often have modifications or limited documentation available. For these vehicles, the VIN becomes an essential reference for identifying production periods and determining matching components. Juncheng Vehicle Industry Group, through its complete vehicle business segment involving classic cars, has accumulated experience in managing compatibility challenges for older vehicles. This experience applies directly to verifying structural differences and selecting compatible sheet metal parts for classic Dodge models. The VIN helps trace original production characteristics and provides a structured means of identifying part variations between early and late versions, supporting restoration and maintenance work.

Advantages of VIN-Based Compatibility Checks for Customers

From the customer’s perspective, providing the VIN simplifies the parts selection process and reduces the possibility of receiving incompatible components. VIN verification minimizes unnecessary returns, shortens consultation time, and enhances confidence in the ordering process. For suppliers such as Juncheng Vehicle Industry Group, receiving VIN data allows engineers to reference internal databases, production drawings, and standard specifications to match Dodge parts more accurately. This improves communication efficiency and contributes to stable supply chain coordination. Customers benefit from reduced installation challenges, while suppliers gain clarity in production planning and inventory allocation.

Limitations of VIN-Based Verification and Supporting Measures

While VIN verification significantly increases accuracy, there are instances where supplemental information may still be required. Aftermarket modifications, regional variations, or undocumented repairs may alter compatibility factors. In such cases, visual inspection, photographs, or part number references might be necessary. Juncheng Vehicle Industry Group uses a combination of VIN interpretation and technical assessment to confirm compatibility in these situations. By integrating engineering analysis with customer-provided vehicle details, the company ensures that the selected Dodge parts reflect the actual condition of the vehicle, enhancing the reliability of compatibility decisions.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体

.jpg)

.jpg)

.jpg)