Are There Any Common Installation Mistakes or Precautions for Cadillac Parts?

Overview of Cadillac Part Installation Requirements

The installation of Cadillac parts requires a controlled and technically informed process due to the brand’s use of multi-material structures, advanced electronic interfaces, and precise fitment characteristics. Cadillac vehicles often integrate aluminum alloys, high-strength steels, composite components, and complex electronic modules, which means that installation accuracy has a direct influence on functionality and long-term performance. Manufacturers such as Juncheng Vehicle Industry Group, which focuses on the development and production of automotive sheet metal components, place significant emphasis on dimensional accuracy, surface treatment quality, and structural precision. While Juncheng primarily supplies sheet metal components and supports complete vehicle production for classic cars, the insights gained from its standardized processing systems offer valuable reference points for understanding correct installation procedures for Cadillac parts. Recognizing common installation mistakes helps technicians avoid operational disruptions, reduce rework, and ensure stability during vehicle operation.

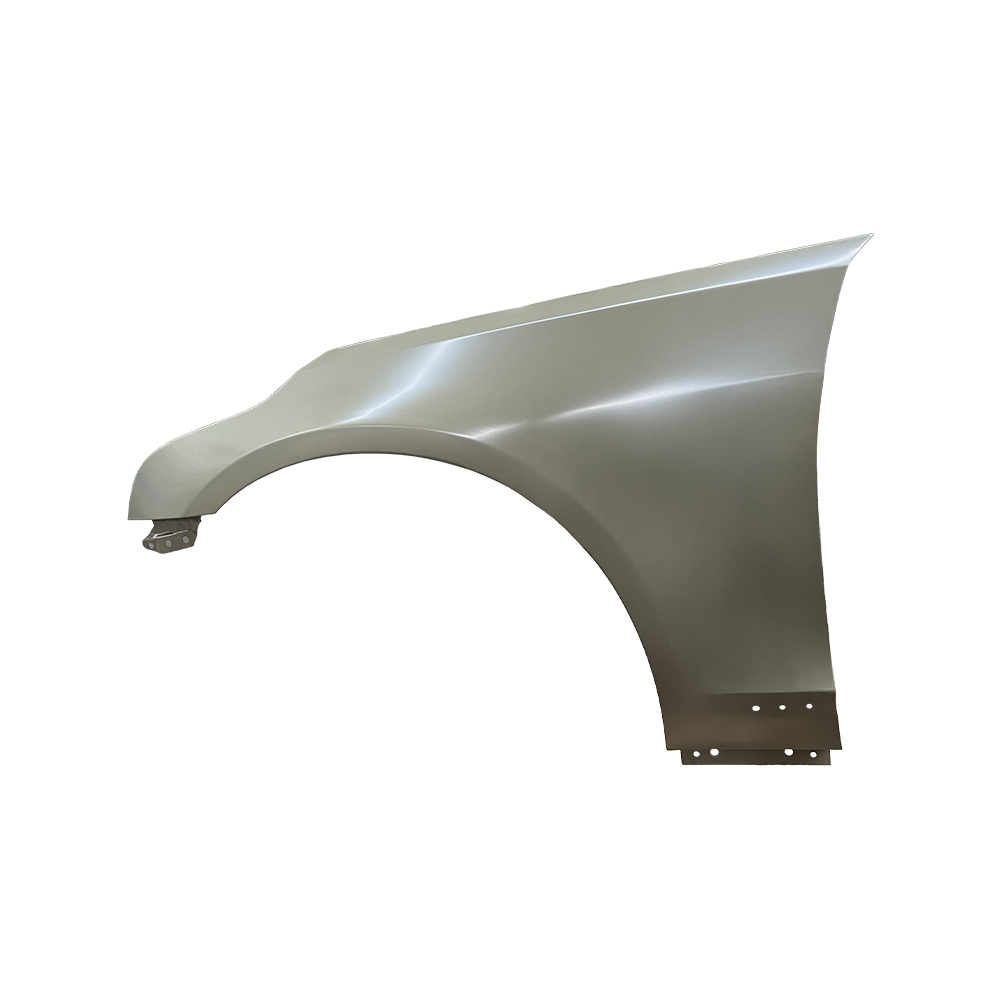

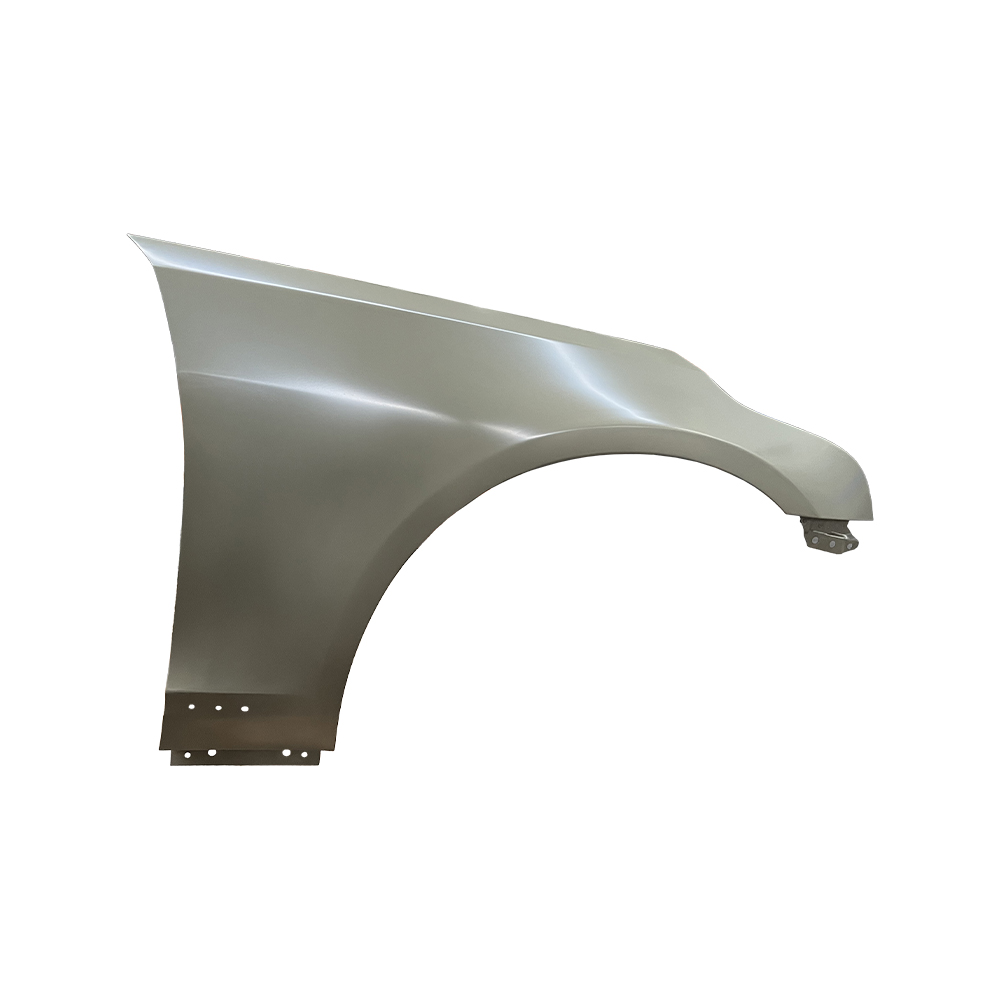

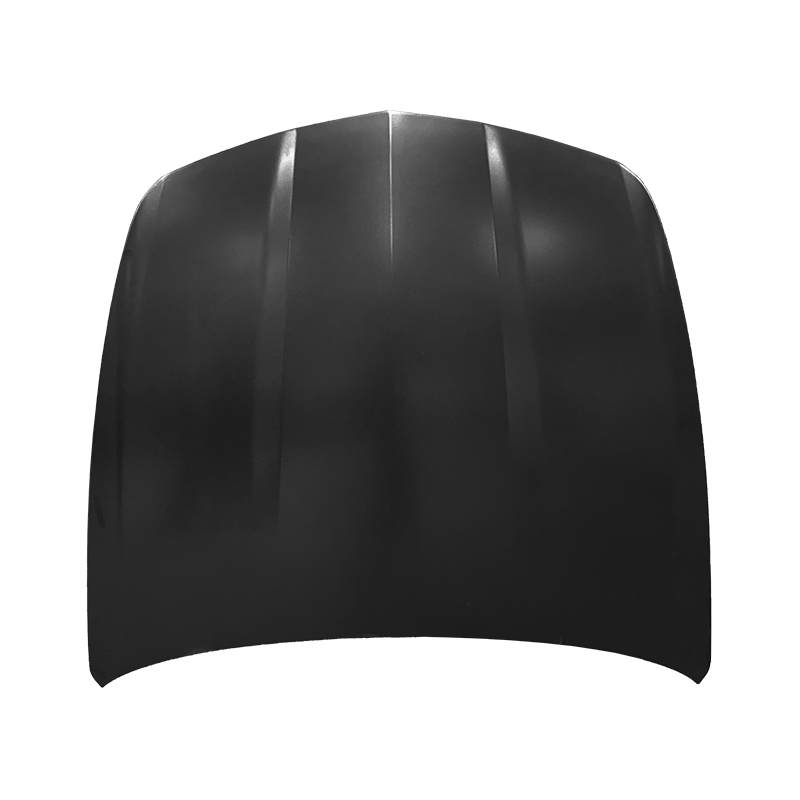

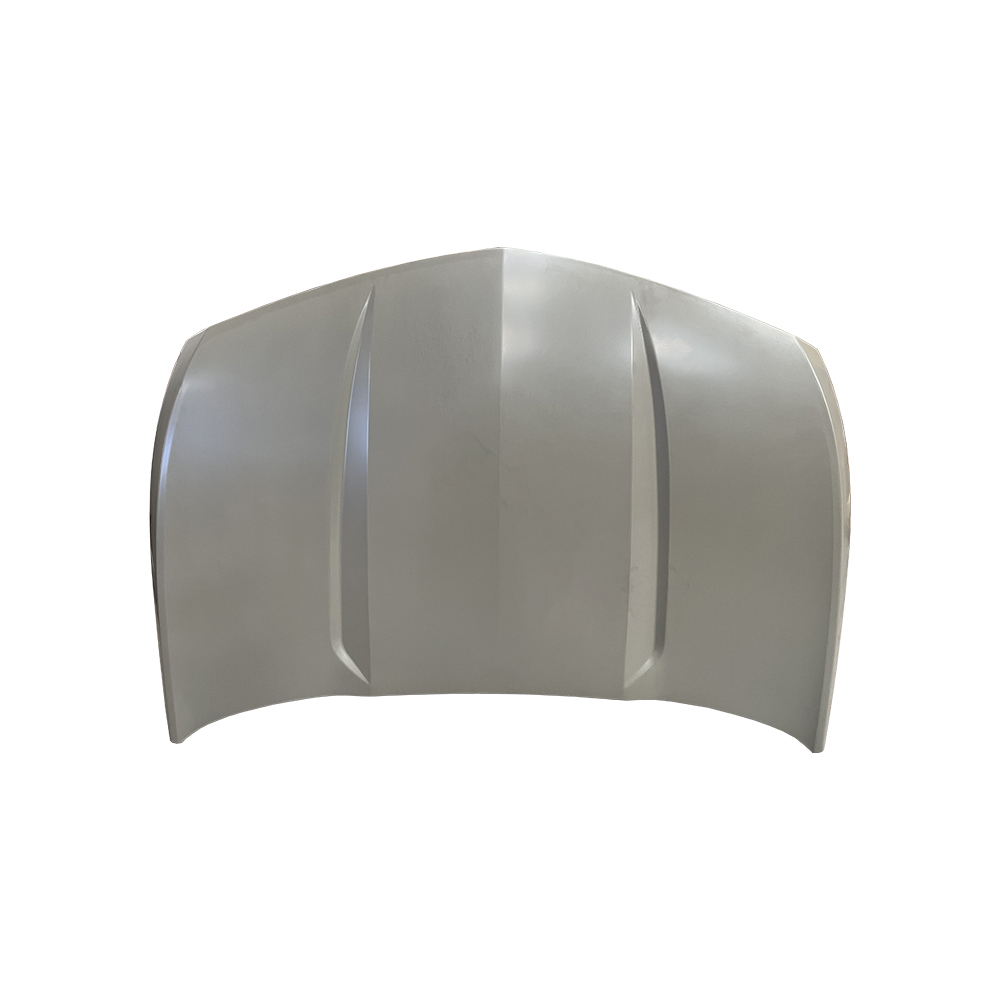

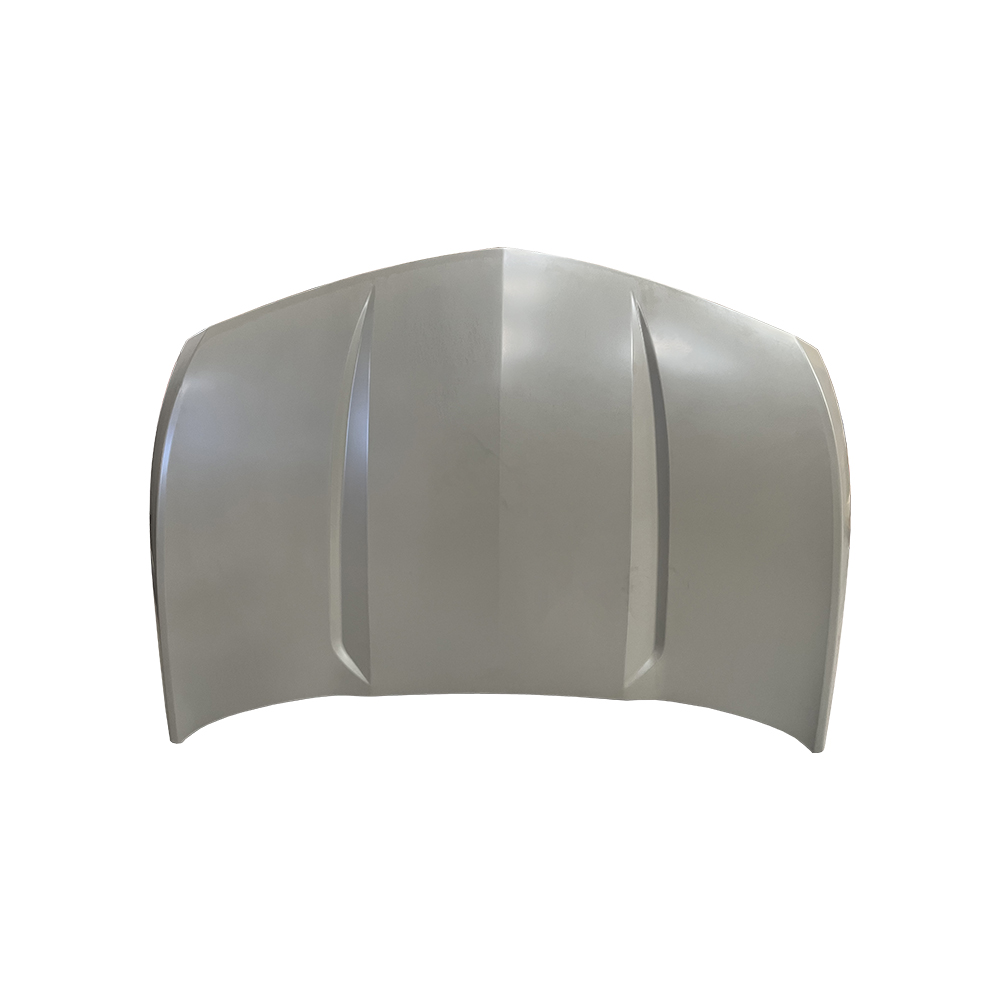

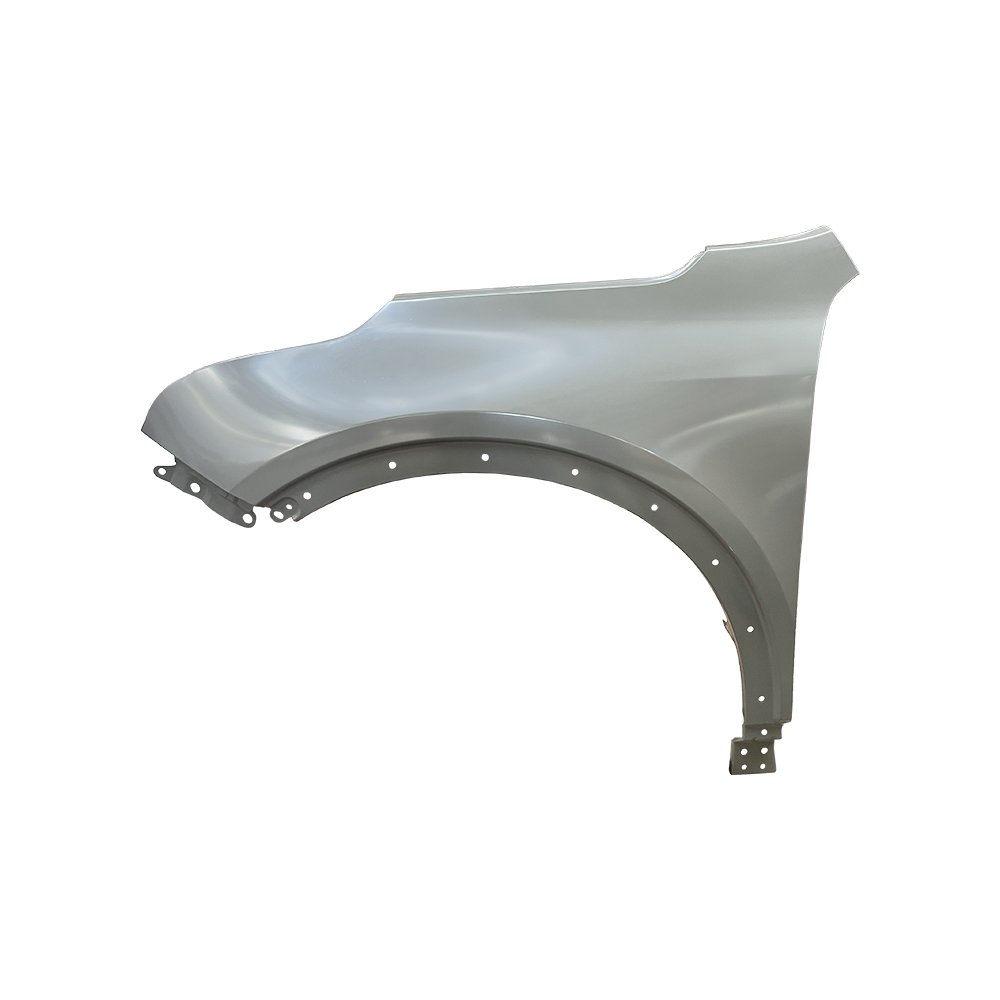

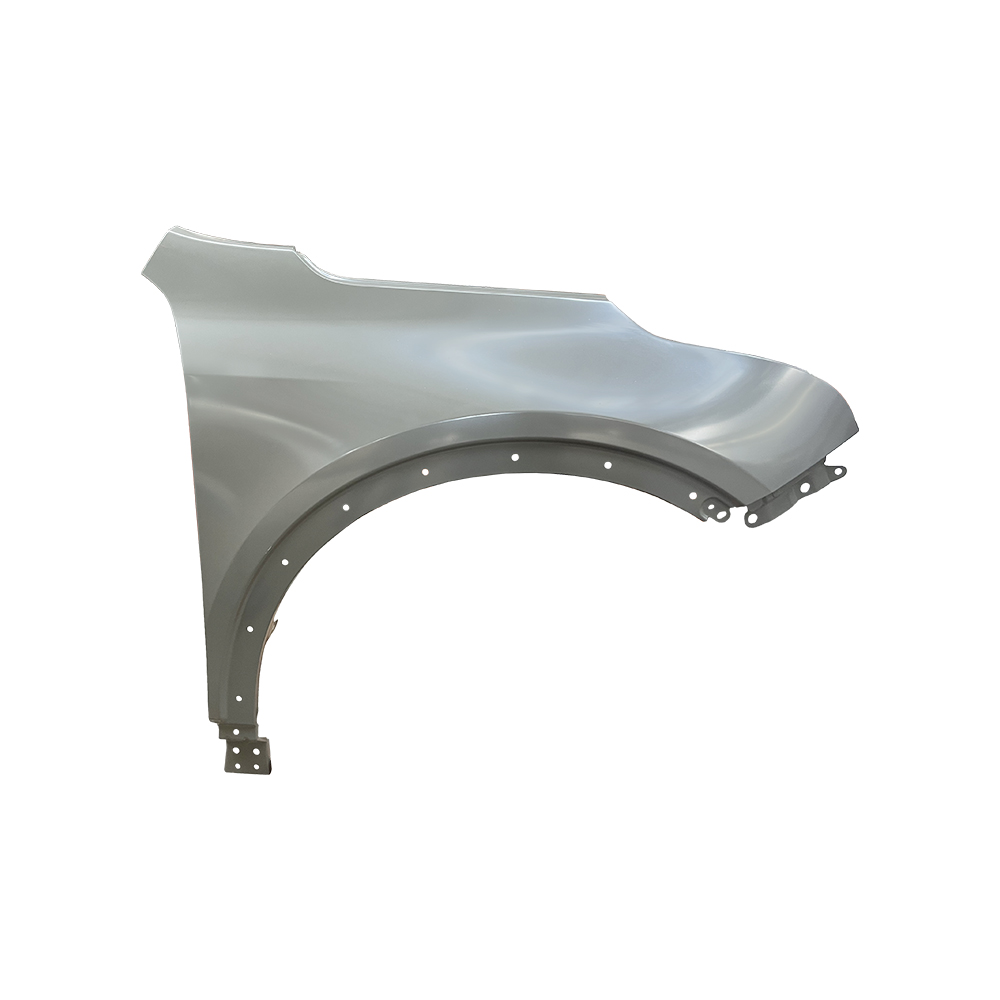

Improper Alignment of Sheet Metal Components

One of the most common installation issues with Cadillac sheet metal parts—such as fenders, hoods, door panels, and rear quarter structures—is improper alignment. These components must match the designated body gaps and flushness parameters; otherwise, the vehicle may experience sealing problems, uneven stress distribution, or unintended noise. Because Cadillac designs rely on tight tolerances, installing a component even slightly off-position may create cumulative deviations across the body structure. Juncheng Vehicle Industry Group, through its focus on precision forming, highlights the importance of verifying body reference points before installation. Technicians must avoid forcing components into position, as this may distort mounting brackets or introduce strain into the metal. Ensuring alignment requires careful measurement, use of factory-specified torque settings, and verification that the body shell itself is within the expected dimensional range.

Incorrect Torque Application During Fastening

Cadillac components, especially those related to body structures, suspension interfaces, or powertrain mounting points, must be installed using the correct torque settings. Over-tightening fasteners may deform sheet metal flanges or mounting brackets, while under-tightening creates risks of loosening during driving. Manufacturers like Juncheng Vehicle Industry Group emphasize the importance of controlled fastening processes in their own production lines, and this principle applies equally to installation procedures. Torque tools must be calibrated, and technicians should rely on Cadillac’s official specification tables rather than approximate values. Failure to apply correct torque can affect structural behavior, particularly in multi-panel assemblies where stress distribution is critical. Ensuring that fasteners are tightened in the correct sequence is also necessary to maintain panel balance and structural uniformity.

Neglecting Surface Protection and Corrosion Control

During installation, technicians sometimes overlook the need to restore surface protection layers after adjusting or modifying components. Cadillac parts often include galvanization layers, electrophoretic coatings, or sealing compounds to prevent corrosion. When sheet metal components are drilled, trimmed, or otherwise adjusted during installation, protective layers may be damaged. Juncheng Vehicle Industry Group’s coating processes highlight the importance of maintaining consistency in surface treatment to ensure long-term part performance. If exposed metal surfaces are not treated with appropriate primers, sealants, or rust-preventive coatings, corrosion may develop. This risk is especially relevant in areas such as wheel wells, door frames, and underbody sections where moisture accumulation is common. A disciplined approach to restoring protective coatings helps maintain the vehicle’s service life.

Electrical Connector Misalignment in Electronic Cadillac Components

Modern Cadillac vehicles integrate a broad range of electronic modules—including sensors, driver assistance systems, lighting units, and communication interfaces. Incorrect connection of these components or poor contact between connectors may cause malfunctions, error codes, or intermittent system failures. The installation of components such as headlamps, tail lamps, and radar units requires careful handling of wire harnesses to prevent bending stress or loose fitment. Technicians must avoid pulling, twisting, or compressing wiring during installation. While sheet metal suppliers like Juncheng Vehicle Industry Group primarily focus on structural parts, their experience with integrated mounting points highlights the need for stable support structures around electrical modules. Ensuring secure and properly oriented connections reduces the likelihood of performance issues following installation.

Failure to Verify Compatibility Before Installation

Cadillac vehicles may undergo generational changes, mid-cycle updates, or model-specific structural adjustments. Installing parts without verifying compatibility can lead to bolt pattern mismatches, incorrect panel curvature, or interference with adjacent assemblies. For example, a door panel designed for one trim level may differ in internal reinforcement layouts compared with another. Juncheng Vehicle Industry Group, with its experience producing components for different vehicle types—including classic cars—recognizes the importance of confirming part compatibility before final installation. Technicians should check part numbers, dimensional specifications, and recommended installation documentation. Accurate verification prevents unnecessary modifications and ensures that the installed part performs as intended.

Common Installation Mistakes and Preventive Measures

| Installation Area | Common Mistake | Potential Impact | Recommended Preventive Measure |

|---|---|---|---|

| Sheet Metal Alignment | Misaligned panels | Poor sealing, noise | Use reference points and measure gaps |

| Fastener Torque | Over/under-tightening | Deformation or loosening | Follow factory torque values |

| Corrosion Protection | Not restoring coating | Rust development | Reapply primers and sealants |

| Electrical Components | Connector misalignment | Intermittent faults | Ensure correct orientation and secure fit |

| Part Compatibility | Incorrect part selection | Fitment issues | Verify part number before installation |

Incorrect Handling of Cadillac Aluminum Components

Many Cadillac vehicles use aluminum panels in areas such as hoods, trunk lids, and front-end structures. Aluminum behaves differently from steel during installation because it is more susceptible to deformation if excessive force is applied. It also requires careful handling to avoid scratches or surface marks, which may later compromise corrosion resistance. Juncheng Vehicle Industry Group’s involvement in multi-material sheet metal production illustrates the importance of controlled force application and protective film usage during installation. Technicians must avoid metal-on-metal contact, should use insulated tools, and should inspect each component before installation to ensure no surface damage is present. Handling aluminum correctly ensures that structural behavior remains within design expectations.

Overlooking Calibration Requirements for Certain Cadillac Components

Certain Cadillac components—including ADAS sensors, headlights, and suspension modules—require calibration after installation. Installing the part without performing calibration may cause functional discrepancies even if the physical installation appears correct. For example, adaptive cruise control sensors require precise alignment to operate accurately. Similarly, headlights equipped with automatic leveling systems must be adjusted to achieve proper illumination patterns. Installation is only one part of the process; calibration ensures that the component integrates correctly with the vehicle’s control systems. Juncheng Vehicle Industry Group’s emphasis on precision manufacturing and component integration serves as a reminder that installation accuracy extends beyond physical fitment and includes functional configuration as well.

Key Precautions for Cadillac Part Installation

Installing Cadillac parts requires more than simply assembling components onto the vehicle structure. Proper alignment, torque application, corrosion control, electrical connection accuracy, and component compatibility all contribute to stable performance and long-term reliability. Manufacturers such as Juncheng Vehicle Industry Group, with their commitment to precision sheet metal production and structured quality control, provide valuable insights into maintaining high installation standards. By following correct installation procedures and avoiding common operational mistakes, technicians can ensure that Cadillac components deliver consistent functionality and integrate smoothly with the vehicle’s manufacturing design. Careful attention to both structural and electronic requirements helps maintain vehicle performance, supports long-term durability, and reduces the risk of post-installation issues.

English

English Español

Español عربى

عربى русский

русский 中文简体

中文简体